Hydro-generator temperature control system used for hydroelectric power generation

A technology of temperature control system and water conservancy power generation, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of difficult realization of process and hidden danger of safe operation of generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

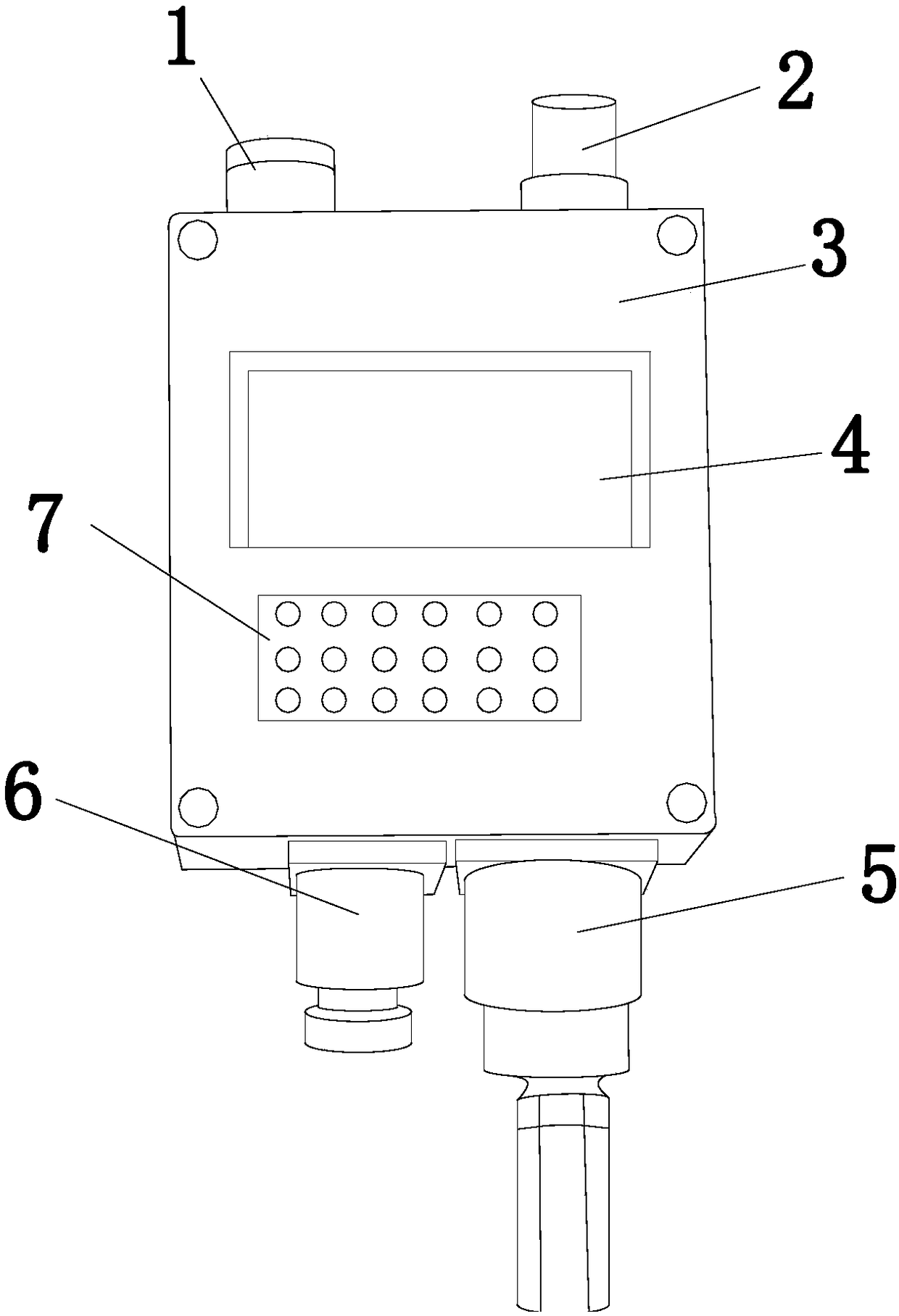

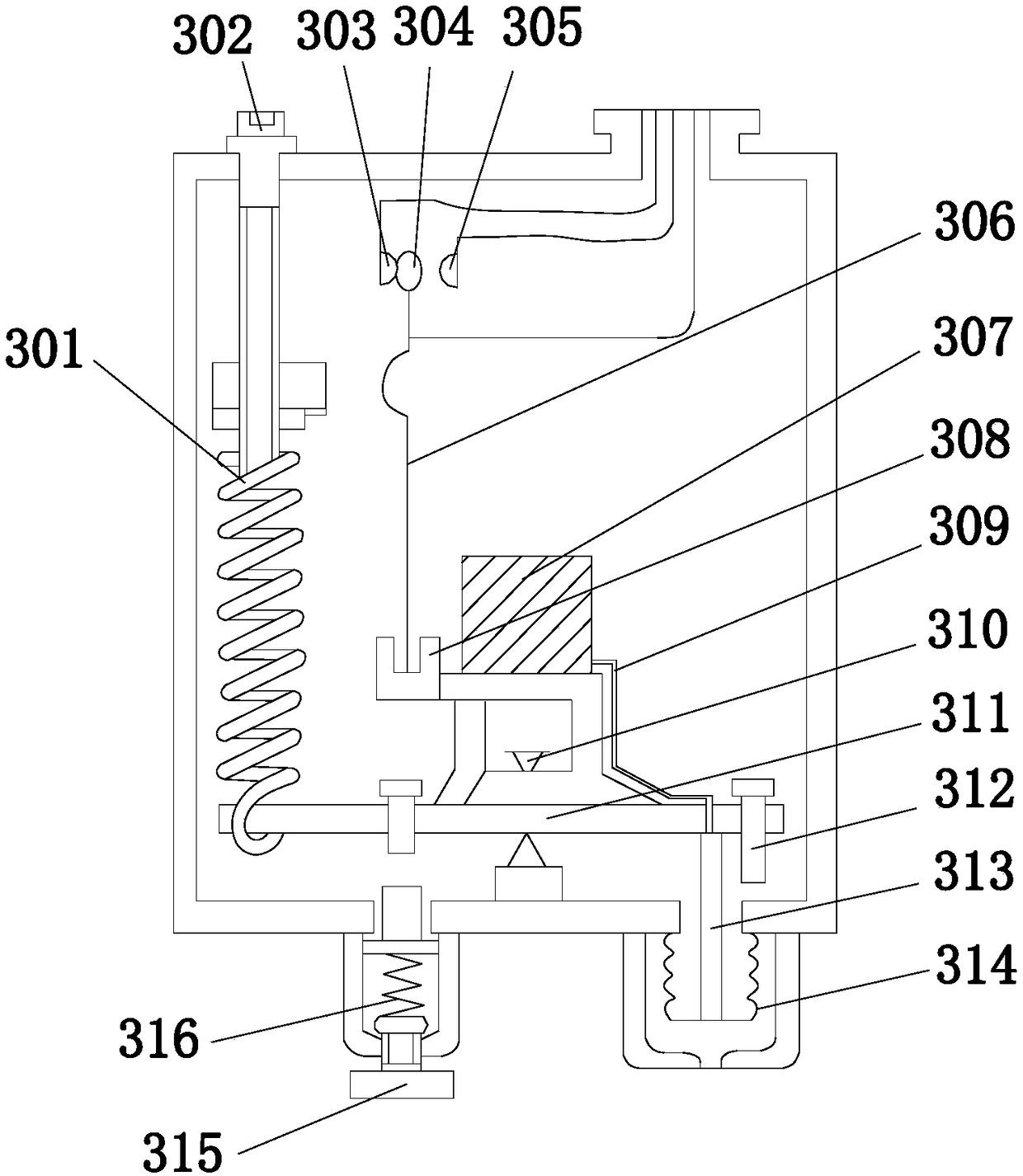

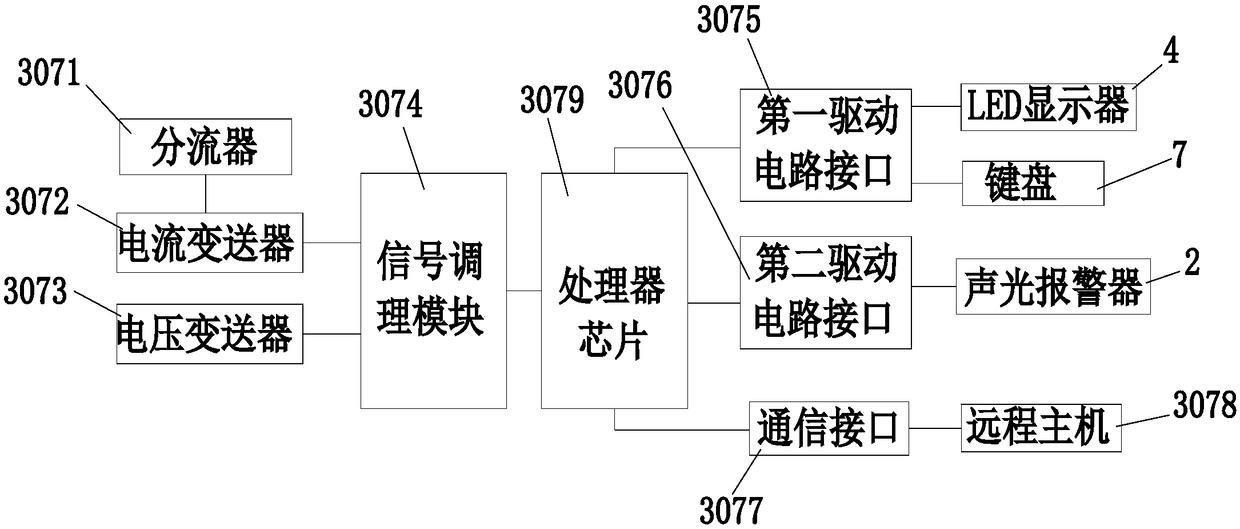

[0026] see Figure 1-Figure 5 , the present invention provides a temperature control system for hydraulic generators for hydraulic power generation, the structure of which includes an adjusting shaft 1, an audible and visual alarm 2, a temperature controller 3, an LED display 4, a bellows casing 5, and a differential spring sleeve 6 , a keyboard 7, an LED display 4 is installed at half of the front end of the temperature controller 3, the signal end of the LED display 4 is electrically connected to the signal of the keyboard 7, and the keyboard 7 and the LED display 4 are located at the same On the plane, the adjusting shaft 1 and the sound and light alarm 2 are fixedly installed on the upper port of the temperature controller 3, and the bellows shell 5 and the differential spring sleeve 6 are mechanically connected to the lower port of the temperature controller 3, so The inside of the temperature controller 3 includes a main spring 301, an adjusting rod 302, a scale 303, a s...

Embodiment 2

[0029] see Figure 1-Figure 6 , the voltage transmitter 3073 is composed of a rear cover 30731, a terminal block 30732, a circuit board 30733, a diaphragm 30734, a sealing ring 30735, a process connector 30736, and an adjustment potentiometer 30737. The inside of the rear cover 30731 is provided with wiring Terminal 30732 and circuit board 30733, the adjustment potentiometer 30737 is welded on the circuit board 30733 and electrically connected to the terminal 30732, the bottom of the circuit board 30733 is provided with a diaphragm 30734, and the diaphragm 30734 is connected to the process connector 30736 A sealing ring 30735 is installed at the joint.

[0030] The model of the voltage transmitter 3073 is SWP-T20 series. In order to improve the accuracy of temperature control, the voltage transmitter 3073 has strong anti-overload and impact resistance, high stability, and high measurement accuracy. Accuracy; its working principle is: the pressure of the measured medium direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com