LED drive circuit with adjustable current

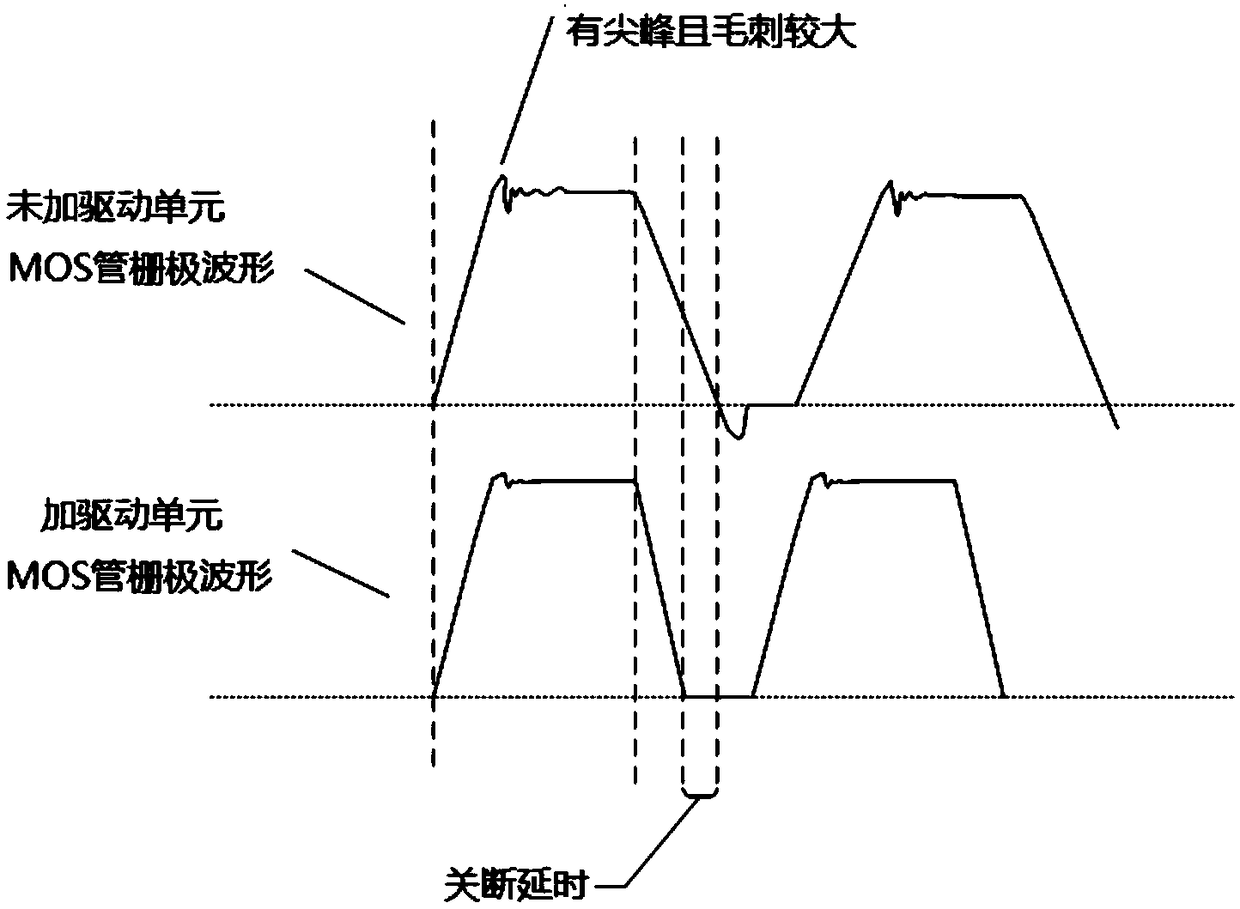

A technology of LED drive and LED lamp group, applied in the direction of electric light source, electrical components, electroluminescent light source, etc., can solve the problems of large current fluctuations flowing through the drive circuit, poor response speed, LED flickering, etc., to achieve Effects of improving efficiency and stability, reducing spikes and glitches, and accelerating turn-off time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

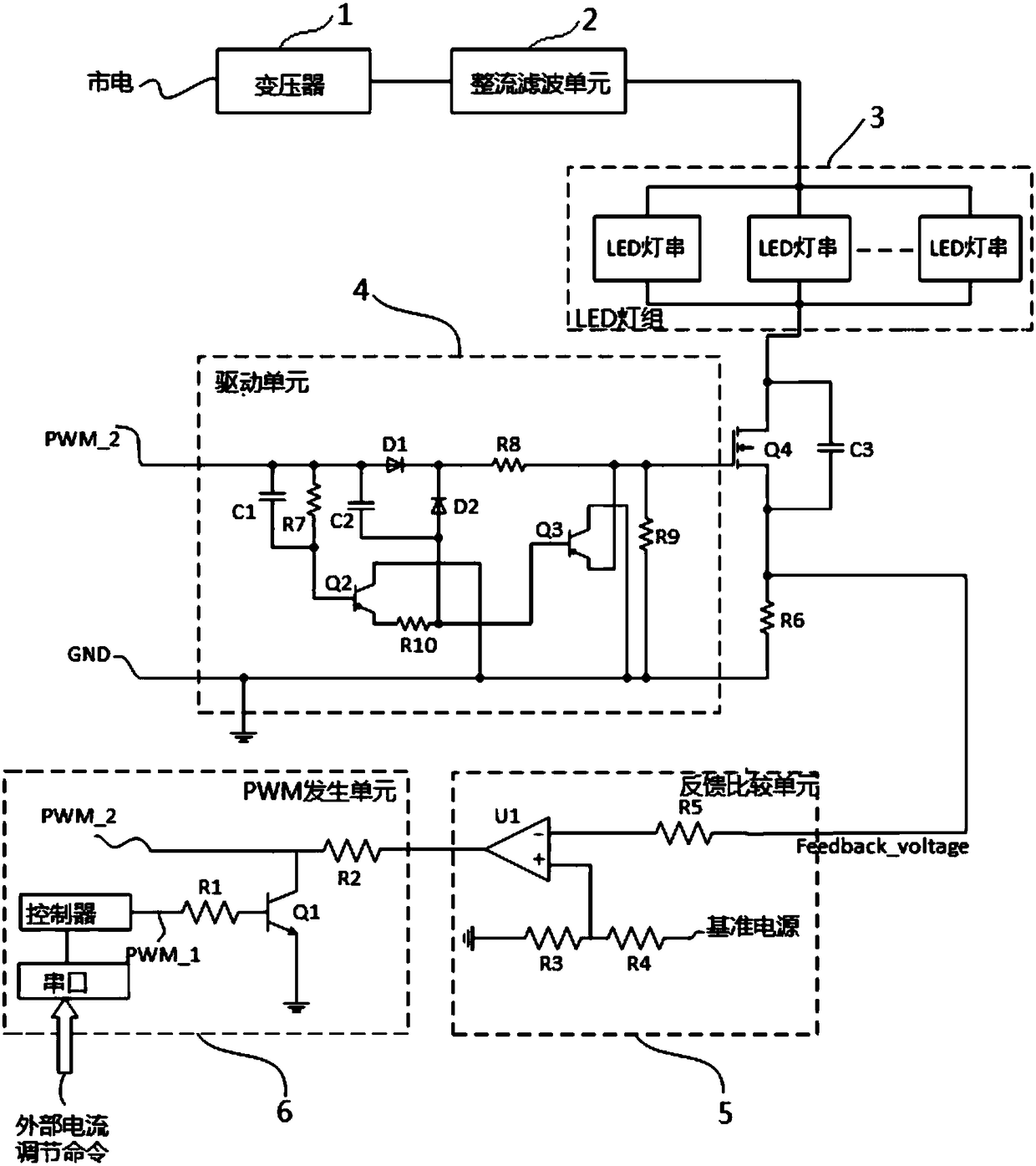

[0010] Such as figure 1 The schematic diagram of the LED drive circuit with adjustable current is shown, including transformer 1, rectification and filtering unit 2, LED lamp group 3, MOS tube Q4, drive unit 4, feedback comparison unit 5 and PWM generation unit 6, and the mains power is stepped down by transformer 1 The output is to the rectification and filtering unit 2, and the rectification and filtering unit outputs a DC power supply connected to the positive pole of the LED lamp group 3 to supply power to the LED lamp group 3. The LED lamp group 3 is composed of multiple LED lamps connected in parallel, and the negative pole of the LED lamp group 3 is connected to the MOS tube Q4 The drain and the source of the MOS transistor Q4 are connected to the feedback comparison unit 5 through the sampling resistor R6, and the MOS transistor Q4, the sampling resistor R6 and the feedback comparison unit 5 form a linear constant current feedback circuit to realize the constant current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com