Cosmetic for oily eyelashes and cosmetic method

A technology for cosmetic materials and eyelashes, applied in the directions of cosmetics, cosmetics, cosmetic preparations, etc., can solve the problems that cannot be said to have removability, insufficient water resistance of sweat and tears, etc., and achieves excellent warm water removability, excellent volume effect, easy The effect of removing makeup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

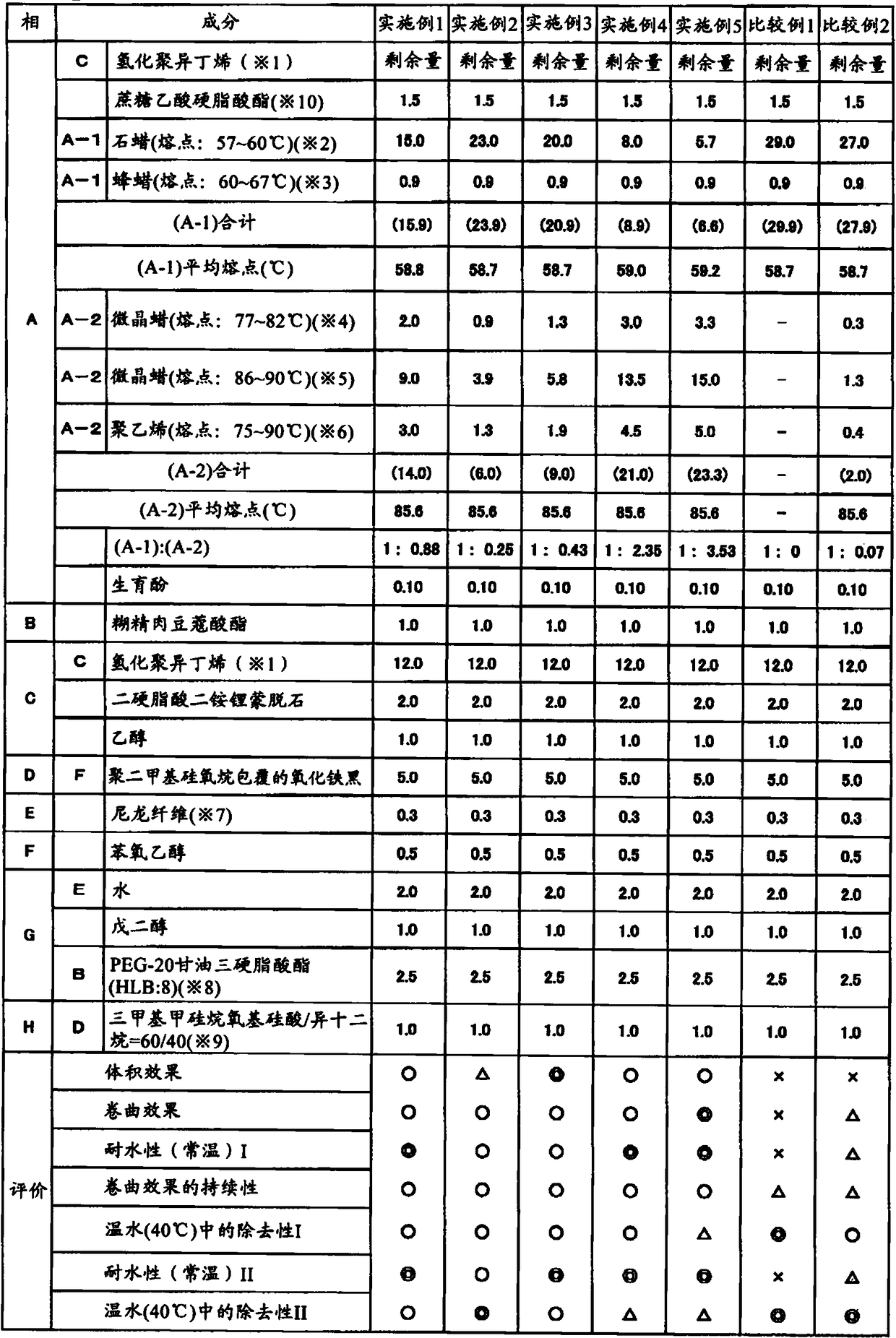

Embodiment 1~5 and comparative example 1~2

[0097]

[0098] The mascara of the formula shown in Table 1 was prepared according to the following manufacturing procedure, and the makeup effect (volume effect / curl effect) of making the eyelashes look thicker, the durability of the makeup effect (water resistance / curl effect) ), and the ease of removal with warm water for sensory evaluation. The results are also shown in Table 1 together.

[0099] (manufacturing process)

[0100] (1) The components of (A) phase to (D) phase shown in Table 1 were heated to about 110° C., and mixed uniformly.

[0101] (2) The (E) to (H) phase components shown in Table 1 were added to the mixed solution obtained in the above (1), and mixed uniformly.

[0102] (3) The mixed solution prepared in (2) above was filled into a container to form an oily mascara.

[0103] [Table 1]

[0104]

[0105] *1: Brand name IP Solvent 1620 (Idemitsu Kosan Co., Ltd.) (boiling point [distillation range]: 166 to 202°C)

[0106] ※2: Trade name paraffin wa...

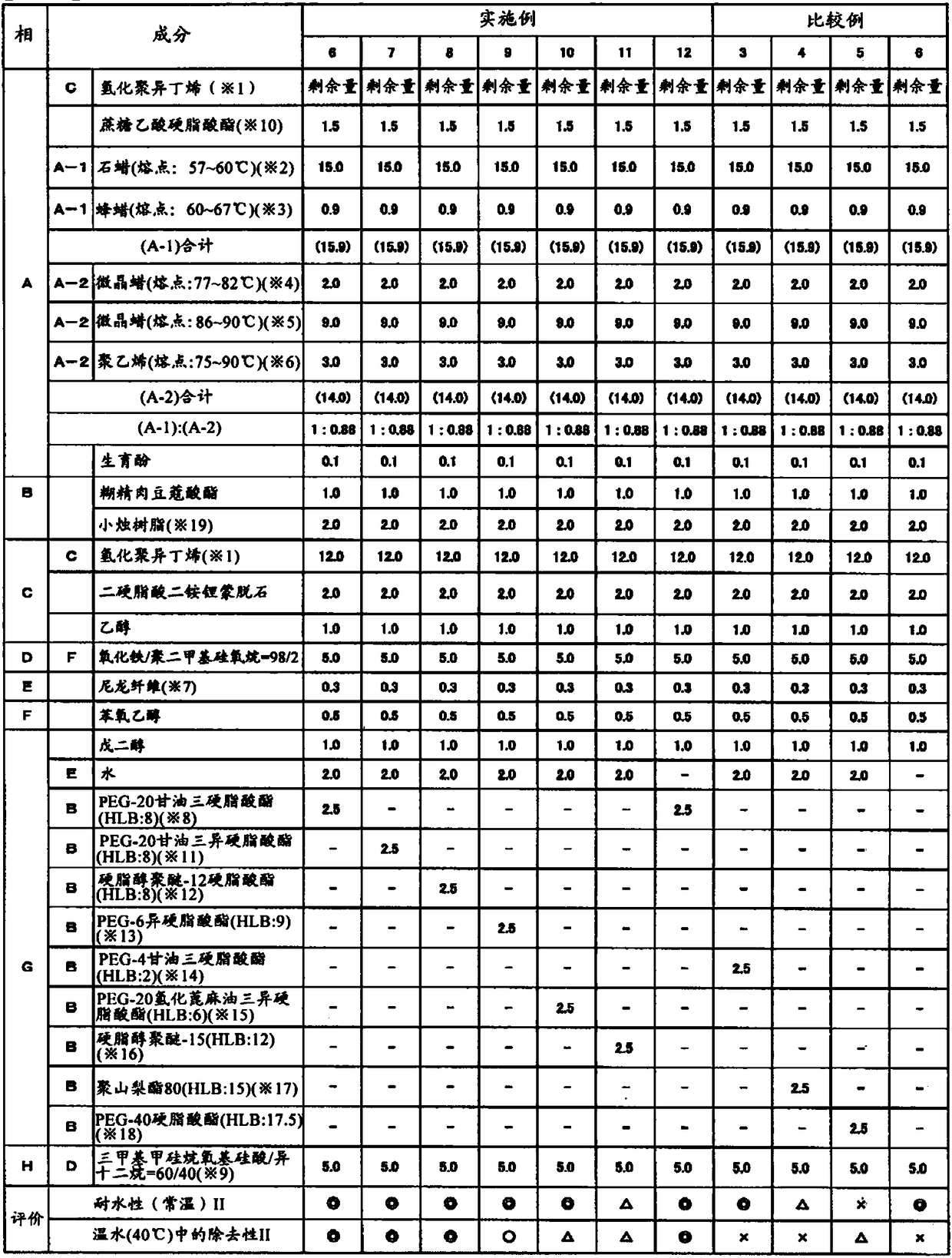

Embodiment 6~12 and comparative example 3~8

[0117]

[0118] Mascaras of the formulations shown in Table 2 were prepared by the same manufacturing procedure as above, and evaluated for water resistance and removability in warm water by the above evaluation methods f and g. The results are shown in Table 2 together with the formulations.

[0119] [Table 2]

[0120]

[0121] ※11: Trade name Uniox GT-20IS (NOF Corporation)

[0122] ※12: Product name EMALEX-SWS-12 (Japan Emulsion Company)

[0123] ※13: Product name EMALEX PEIS-6EX (Emulsion Corporation of Japan)

[0124] ※14: Product name EMALEX-GWS-304 (Emulsion Corporation of Japan)

[0125] ※15: Product name EMALEX RWIS-320 (Japan Emulsion Company)

[0126] ※16: Product name EMALEX 615 (Japan Emulsion Company)

[0127] ※17: Brand name Rheodol TW-O 120V (Kao Corporation)

[0128] ※18: Brand name NIKKOL MYS-40V (Nikko Chemical Co., Ltd.)

[0129] ※19: Trade name Candelilla resin E-1 (Natural Products, Japan)

[0130] As can be seen from the results in Table 2, ...

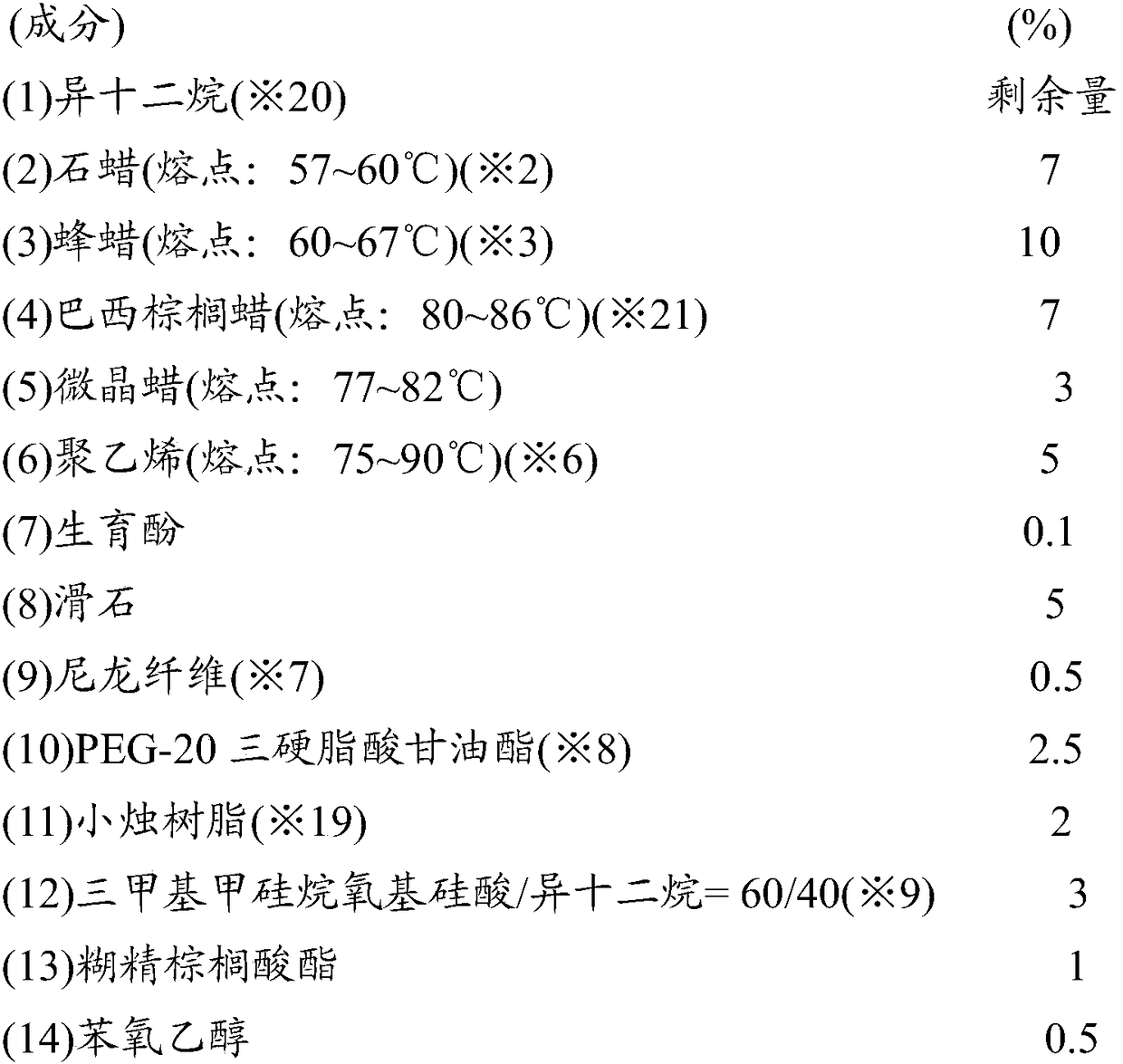

Embodiment 11

[0132]

[0133] Using the ingredients shown below, a mascara base was prepared according to the following manufacturing procedure.

[0134]

[0135]※20: Product name CREASIL ID CG (manufactured by CIT Sarl)

[0136] *21: Trade name deodorant purified carnauba wax No.1 (manufactured by Cerarica Noda Co., Ltd.)

[0137] (manufacturing process)

[0138] A. Components (1) to (14) are made uniform at about 110°C.

[0139] B. The mixed solution obtained in A above is filled in a container to form a base for mascara.

[0140] When the mascara base obtained above was applied to the eyelashes and then a commercially available mascara (Dejavu Fiberwig Ultra Long a) was used, the curling effect and water resistance were better than those without the mascara base. In addition, when removing makeup only with warm water at about 40°C, the base for mascara can be easily removed together with the mascara.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com