Cellulose-based insulation and methods of making same

A thermal insulation material, cellulose technology, applied in the direction of manufacturing tools, fiber processing, building materials, etc., to achieve the effect of reducing floor space, reducing capital costs, and being cost-competitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

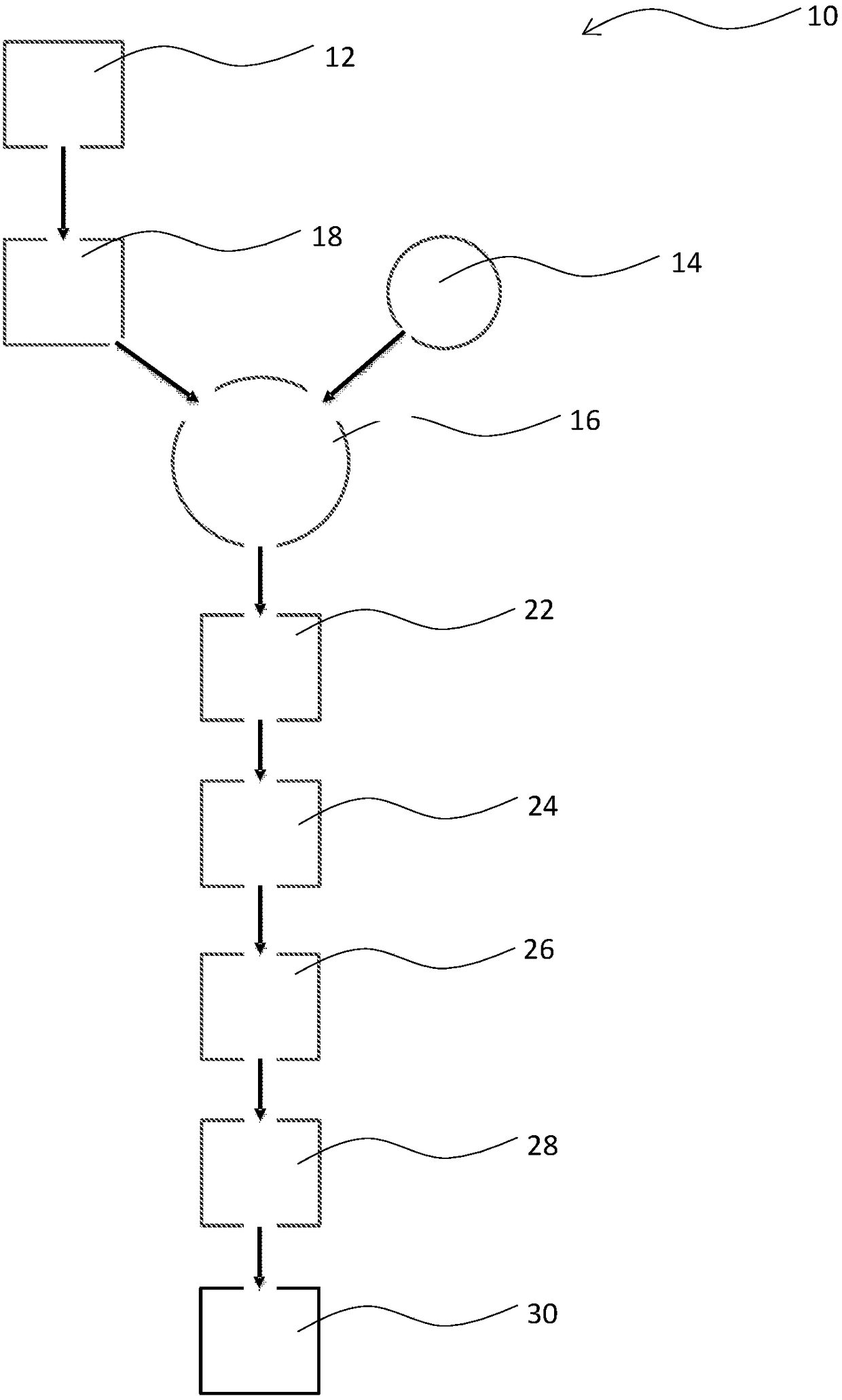

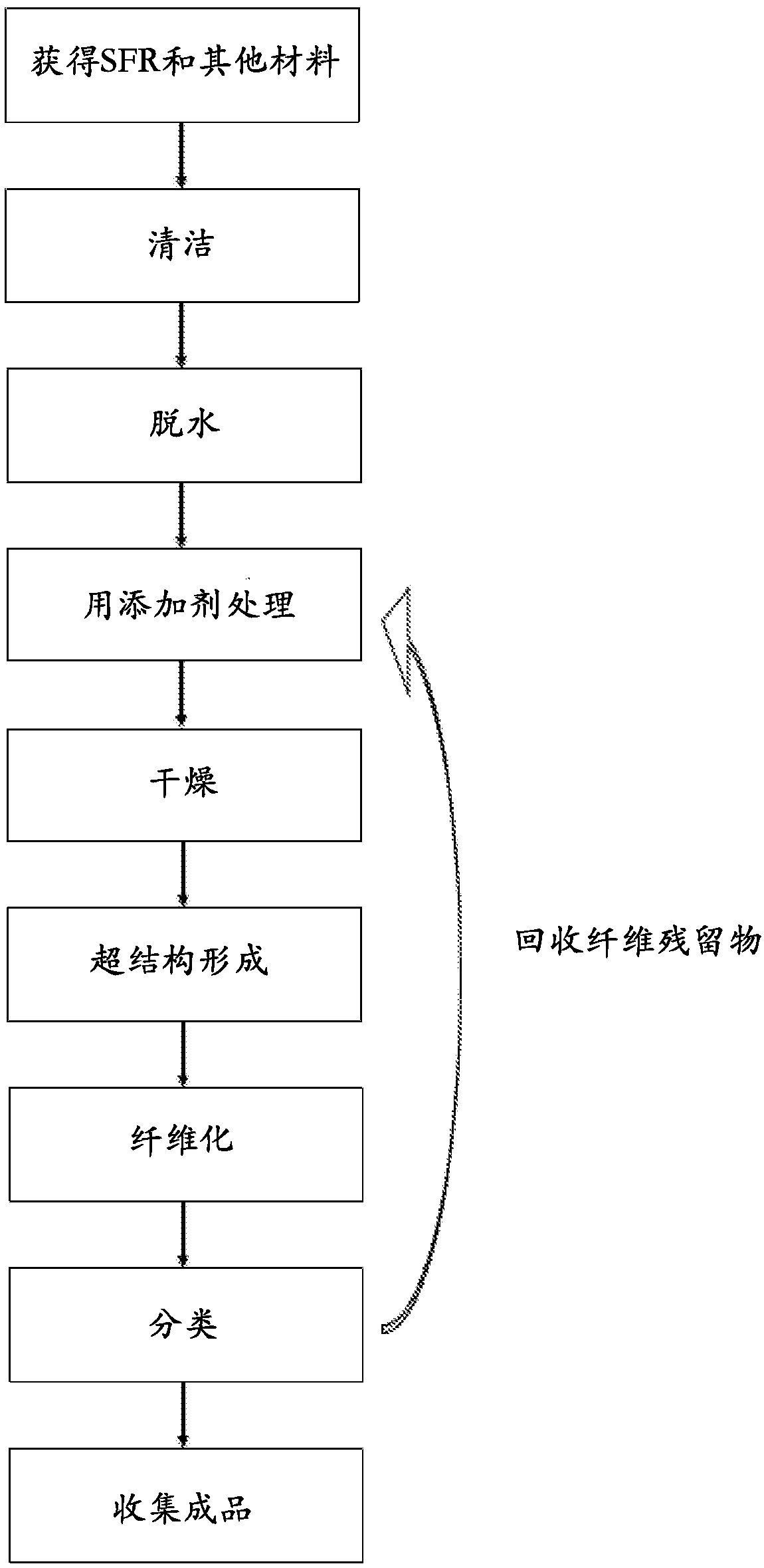

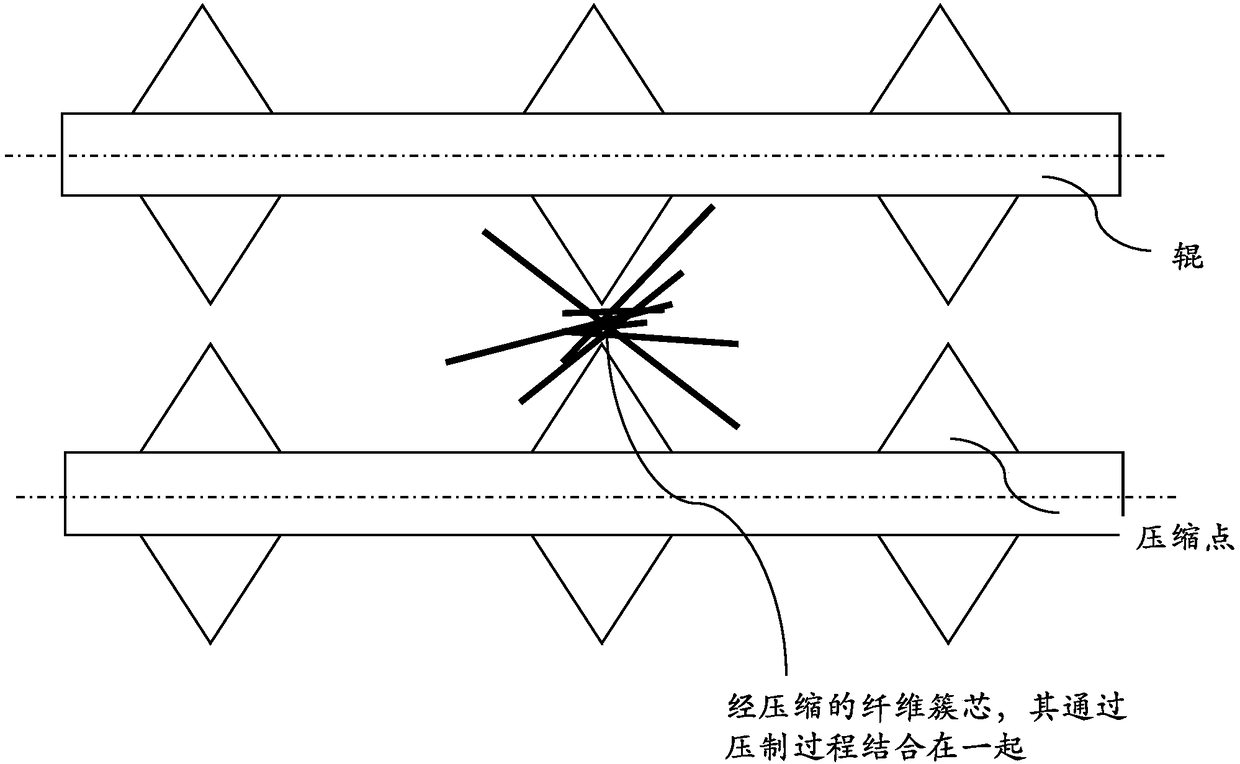

[0040] figure 1 A simplified representation of the main components of a system 10 for making a flame-retardant cellulose-based thermal insulation material of the present invention is shown in Figure 5 shown in . The insulating material of the present invention includes superstructural configurations of the raw material from which it is made which enhance the void characteristics and thus improve the thermal performance characteristics of the insulating material. The insulating material can be installed in place, for example by blowing or spraying it into place, while maintaining the integrity of the superstructure and thus the void integrity of the insulating material after installation. The main steps of the method for manufacturing the cellulose-based thermal insulation material of the present invention are in figure 2 shown in .

[0041] System 10 can be as figure 1 The configuration is shown and includes a feedstock source container 12, a chemical processing source 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com