Barrier structure made from mxdt/xt copolyamide with high tg

一种共聚酰胺、结构体的技术,应用在阻隔结构体领域,能够解决没有提及结构体阻隔性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

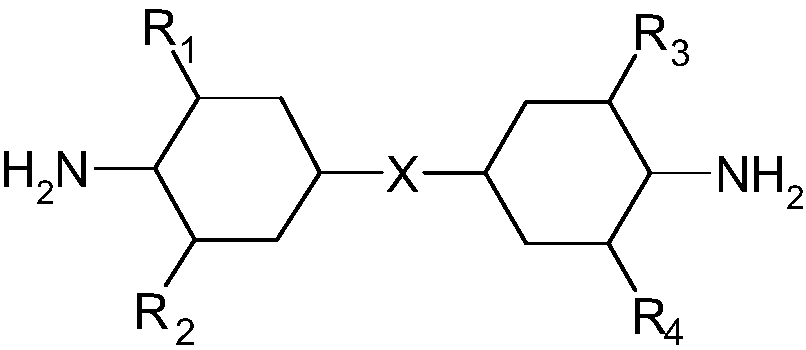

Method used

Image

Examples

Embodiment

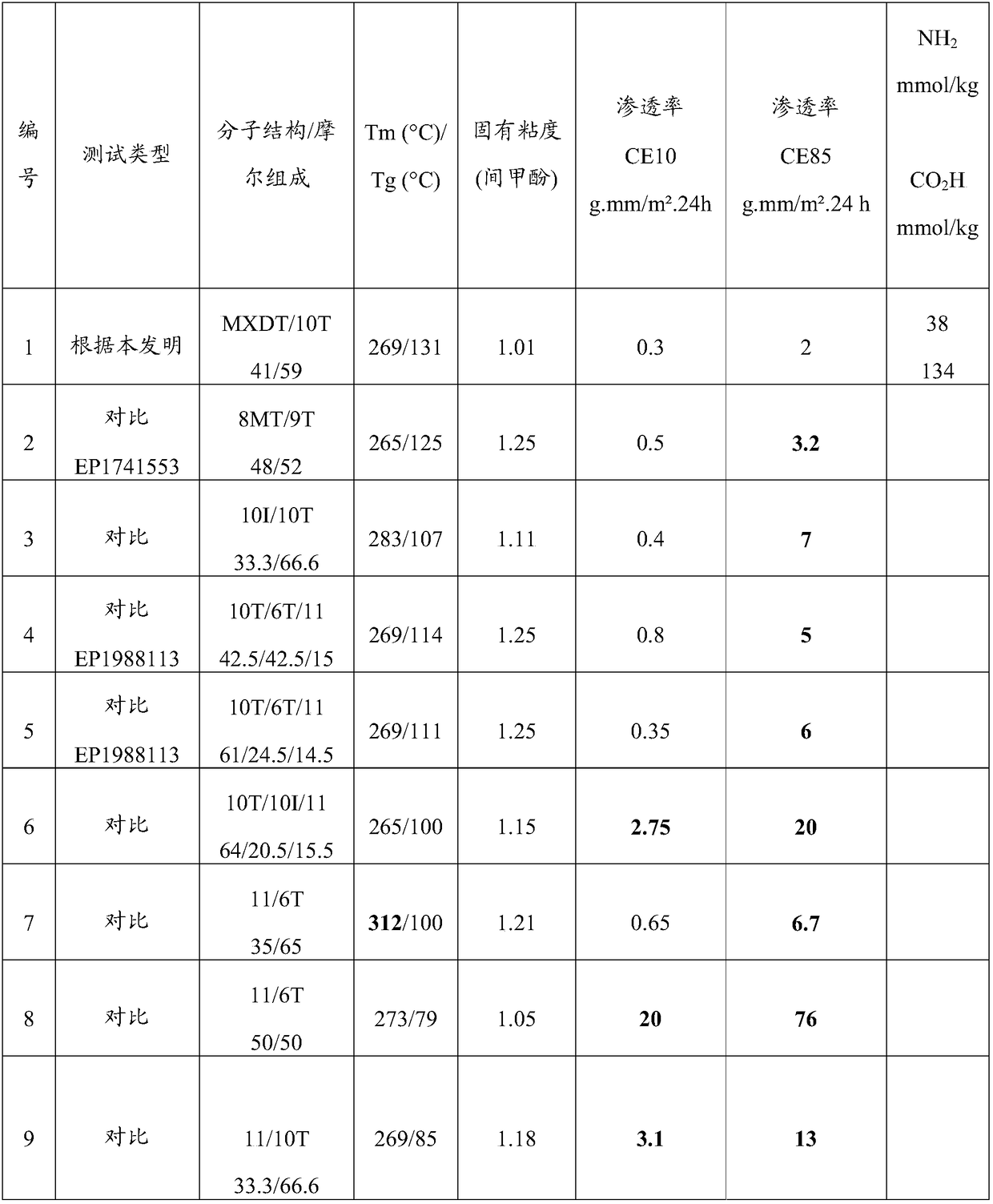

[0239] 1) Preparation of MXDT / 10T and comparative polyamide

[0240] 5 kg of the following feedstock were introduced into a 14 liter autoclave reactor:

[0241] -500g water,

[0242] - one or more diamines,

[0243] - amino acids (optional),

[0244] - one or more diacids,

[0245] - monofunctional chain regulator: benzoic acid or stearic acid in an amount suitable for the target viscosity,

[0246] - 35 g of sodium hypophosphite in solution,

[0247] - 0.1 g Wacker AK1000 defoamer (Wacker Silicones).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com