Oil-in-water light foundation makeup

An oil-in-water and foundation technology, applied in the directions of body powder, cosmetic preparations, dressing preparations, etc., can solve the problems of messiness, large spreading resistance, and color difference of makeup, and achieve the effect of good makeup retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

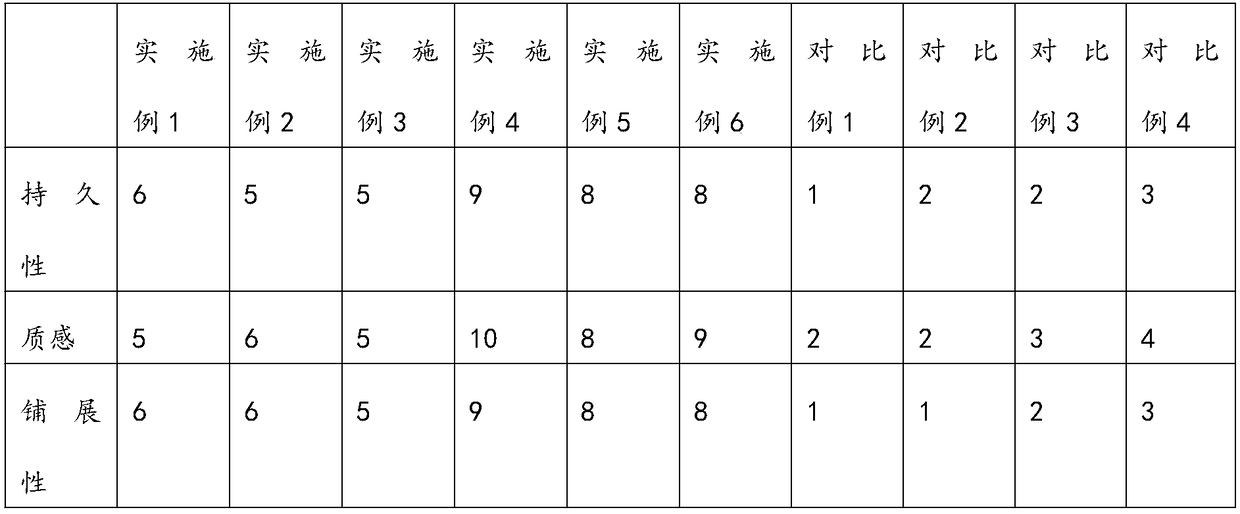

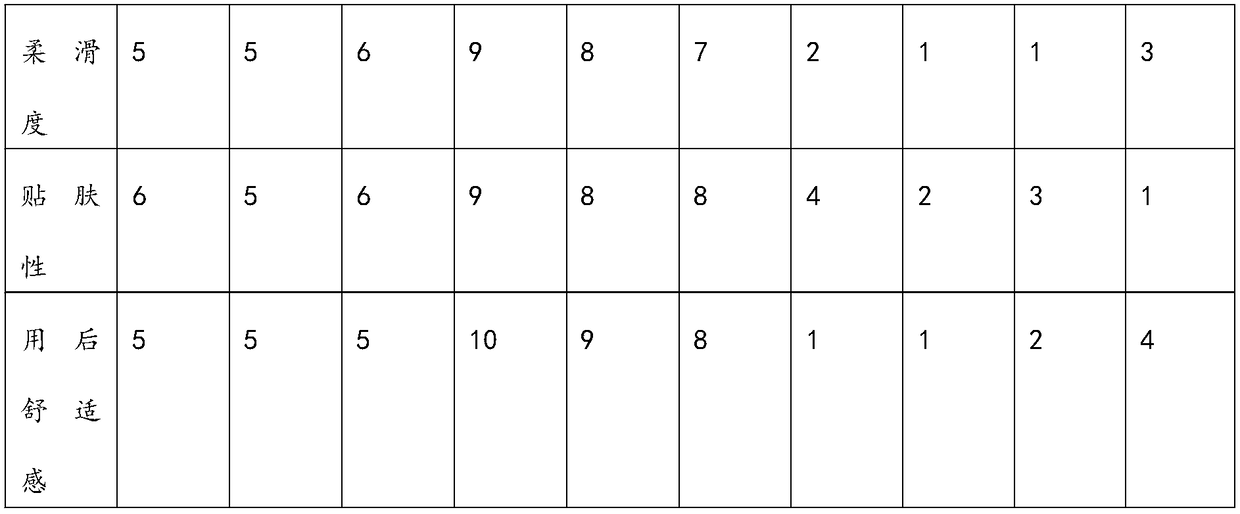

Examples

Embodiment 1

[0016] An oil-in-water lightweight foundation, containing the following components in mass percentage: 1.5% of C20-22 alcohol phosphate, 0.3% of PEG-100 stearate, 0.5% of sorbitan sesquiisostearate, octyl Polymethicone 10%, Dimethiconol 1%, Hydrogenated Polyisobutylene 3%, Pentaerythritol Tetraisostearate 3%, Talc 1.5%, Titanium Dioxide 8%, Iron Oxide 1.5% %, Polyacrylate Crosslinked Polymer-60.3%, Carbomer 0.15%, Dipropylene Glycol 8%, Glyceryl Polyether-262%, PEG / PPG / Polybutylene Glycol-8 / 5 / 3 Glycerin 2.5% , 0.1% of p-hydroxyacetophenone, 0.4% of 1,2-hexanediol / caprylyl glycol, 0.2% of triethanolamine, 0.1% of arginine, and the balance of water.

[0017] The talcum powder, titanium dioxide and iron oxide are all surface-treated powders, and the surface treatment agent is perfluorooctyltriethoxysilane.

Embodiment 2

[0019] An oil-in-water light foundation, containing the following components in mass percentage: 1% of C20-22 alcohol phosphate, 0.5% of PEG-100 stearate, 0.1% of sorbitan sesquiisostearate, octyl Polymethicone 15%, Dimethiconol 0.1%, Hydrogenated Polyisobutylene 5%, Pentaerythritol Tetraisostearate 1%, Talc 3%, Titanium Dioxide 5%, Iron Oxides 2 %, Polyacrylate Crosslinked Polymer-60.1%, Carbomer 0.5%, Dipropylene Glycol 5%, Glycerol Polyether-261%, PEG / PPG / Polybutylene Glycol-8 / 5 / 3 Glycerin 5% , phenoxyethanol / ethylhexylglycerin 0.2%, sodium hydroxide 0.4%, water balance.

[0020] The talcum powder, titanium dioxide and iron oxide are all surface-treated powders, and the surface treatment agent is perfluorooctyltriethoxysilane.

Embodiment 3

[0022] An oil-in-water light foundation, which contains the following components in mass percentage: 3% of C20-22 alcohol phosphate, 0.1% of PEG-100 stearate, 1% of sorbitan sesquiisostearate, octyl Polymethicone 5%, Dimethiconol 2%, Hydrogenated Polyisobutylene 1%, Pentaerythritol Tetraisostearate 5%, Talc 0.1%, Titanium Dioxide 15%, Iron Oxide 0.5% %, Polyacrylate Crosslinked Polymer-60.6%, Carbomer 0.1%, Dipropylene Glycol 7%, Glyceryl Polyether-267%, PEG / PPG / Polybutylene Glycol-8 / 5 / 3 Glycerin 1% , 0.7% of p-hydroxyacetophenone, 0.1% of potassium hydroxide, and the balance of water.

[0023] The talcum powder, titanium dioxide and iron oxide are all surface-treated powders, and the surface treatment agent is perfluorooctyltriethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com