Low-loss high-speed cable and flat cable

A low-loss, high-speed technology, used in cables, insulated cables, communication cables, etc., can solve the problems of low dielectric constant consistency, large signal attenuation loss, poor high temperature resistance, etc., to ensure stable and effective transmission, The effect of reducing signal attenuation loss and high dielectric constant consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

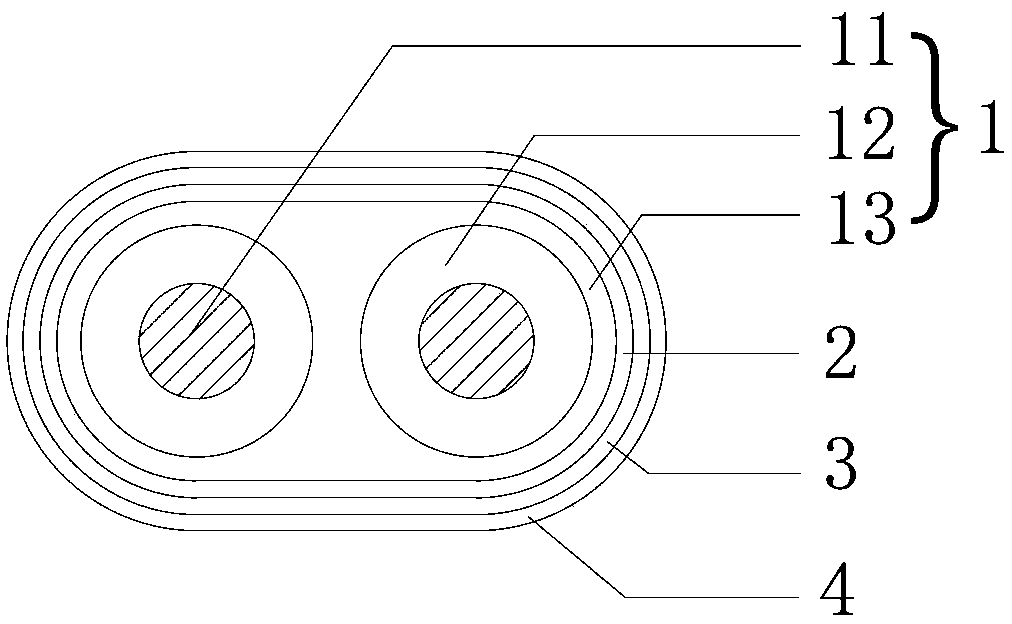

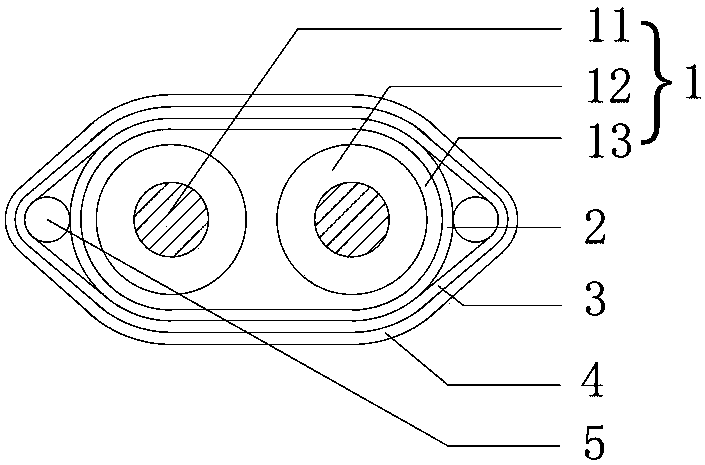

[0023] Such as figure 1 and figure 2 As shown, a low-loss high-speed cable includes a core group 1, a first shielding layer 2, a second shielding layer 3 and an outer coating layer 4; the first shielding layer 2 is wrapped outside the core group 1 , the second shielding layer 3 is wrapped outside the first shielding layer 2, and the outer layer 4 is wrapped outside the second shielding layer 3; the core set 1 includes two inner conductors 11, two The inner conductor 11 is covered with a first perfluoroethylene propylene copolymer insulating layer 12 separately, and the two first perfluoroethylene propylene copolymer insulating layers 12 are covered with a second perfluoroethylene propylene copolymer extruded at the same time. The physical insulating layer 13, the cross-sectional shape of the second perfluoroethylene propylene copolymer insulating layer 13 is racetrack-shaped.

[0024] Such as figure 1 and figure 2 As shown, the first shielding layer 2 is a copper foil la...

Embodiment 2

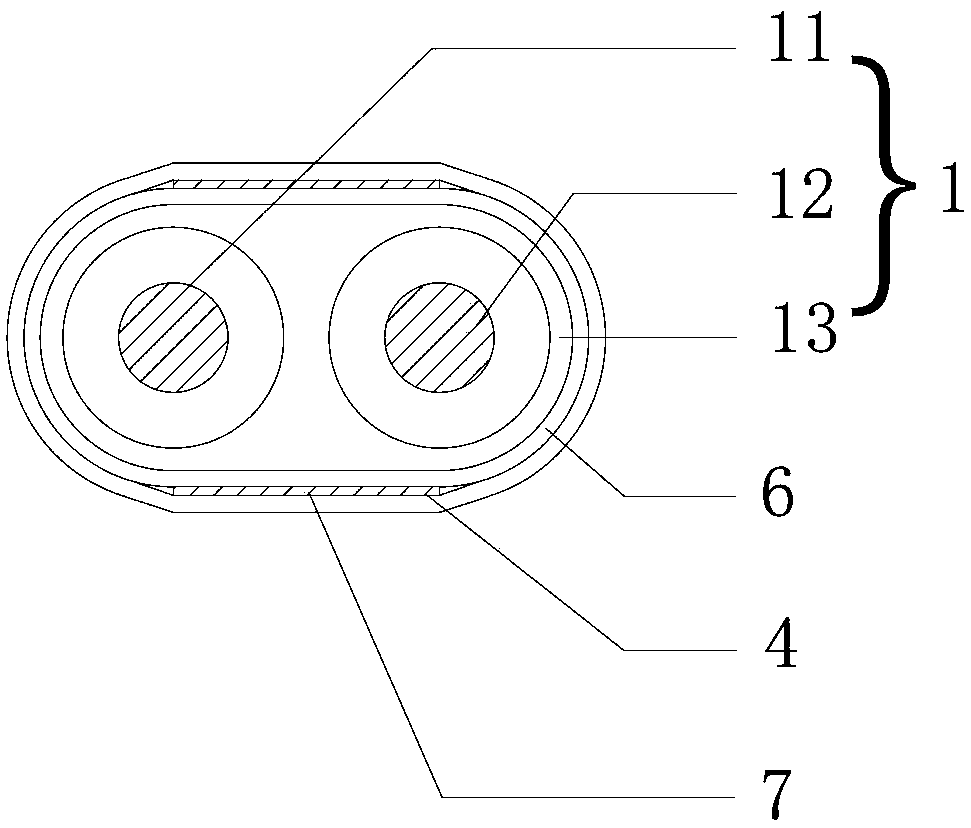

[0028] Such as image 3 As shown, a low-loss high-speed cable includes a core group 1, a shielding layer 6 and an outer coating layer 4; the shielding layer 6 is covered outside the core group 1, and the outer coating layer 4 is coated on the Outside the shielding layer 6; the core group 1 includes two inner conductors 11, and the two inner conductors 11 are separately covered with a first perfluoroethylene propylene copolymer insulating layer 12, and the two first perfluoroethylene propylene copolymers The outside of the material insulating layer 12 is covered with a second perfluoroethylene propylene copolymer insulating layer 13 extruded simultaneously, and the cross-sectional shape of the second perfluoroethylene propylene copolymer insulating layer 13 is racetrack-shaped; the shielding layer 6 and the outer Two flat ground wires 7 are sandwiched between the layers 4 , and the two flat ground wires 7 are located on the upper and lower sides of the shielding layer 6 .

[0...

Embodiment 3

[0031] Such as Figure 4 As shown, a low-loss high-speed flat cable is composed of at least two groups of low-loss high-speed cables arranged in the first technical solution above, and each low-loss high-speed cable is also covered with a second thermal insulation layer. Melt PET tape layer8. The low-loss high-speed cables are horizontally connected in a row through the second hot-melt PET tape layer 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com