Millimeter-level flow control technology-based water-soluble core blast bead preparing method

A water-soluble, high-tech technology, applied in e-liquid filter elements, applications, tobacco, etc., can solve the problems of low embedding rate and core material utilization, wall material deterioration and mold, poor preservation effect, etc., to achieve low production cost, Simple preparation method and strong controllability of wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of water-soluble core material pop-up beads with a size of 2mm

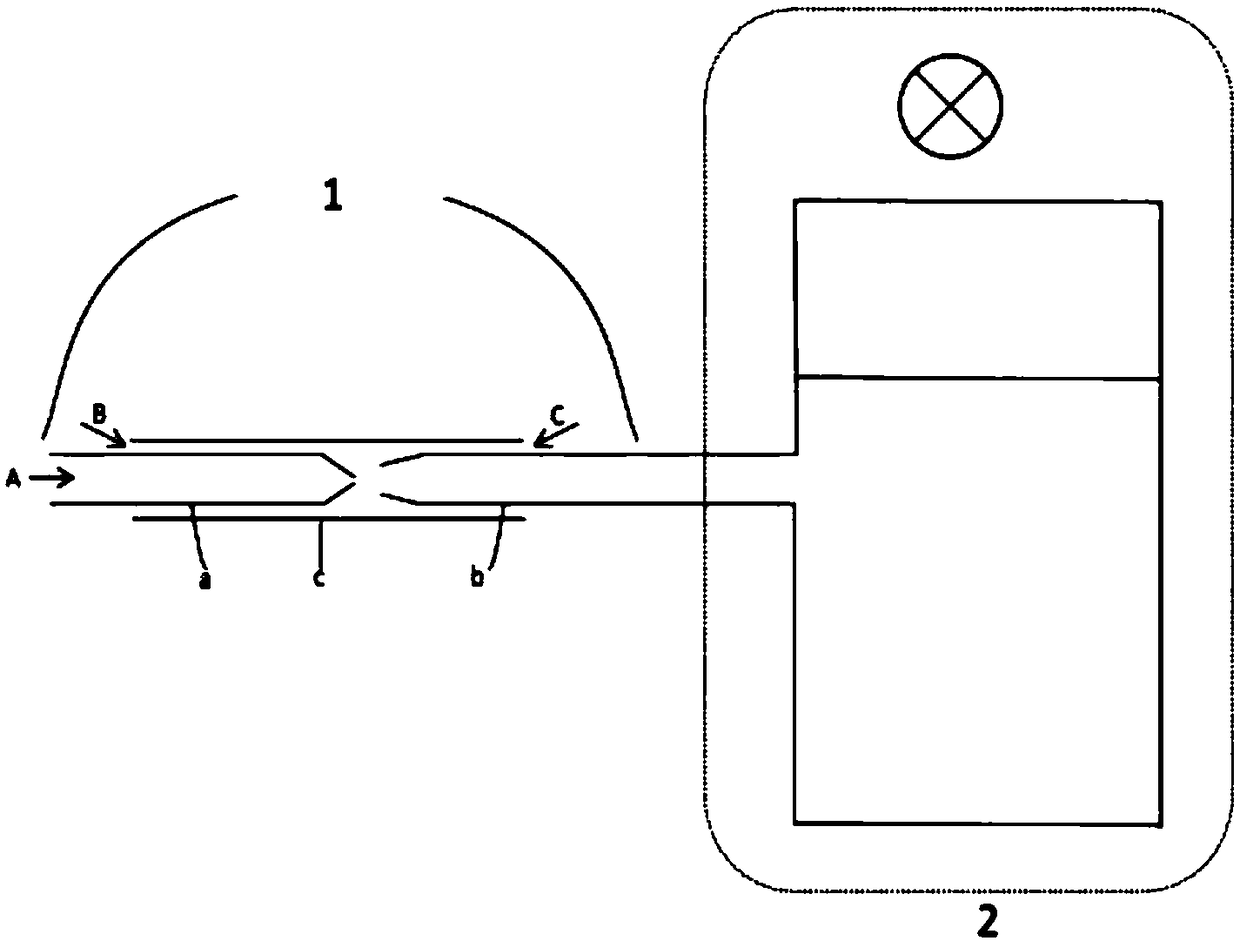

[0030] The outer diameter of the tip of the inner tube (a) is 1.15mm, the inner diameter of the tip of the inner tube (b) is 1.85mm, the distance between the two tips is 2-2.5mm, the inner diameter of the non-tip part of the two inner tubes is 2.25mm, the outer diameter is 3mm, and the inner diameter of the outer tube (c) is 3.13mm mm. Inner phase selects perfume aqueous solution (containing 30% ethanol solution), and intermediate phase selects the epoxy acrylate resin containing 2wt.% photoinitiator I-184, and external phase selects the water containing 1wt.% F108, internal phase, intermediate phase and The external phase is pumped into A, B, and C of the three-dimensional confocal emulsion generation channel 1 at 10mL / h, 12mL / h, and 110mL / h respectively, and W / O / W emulsification is generated through the action of shear force and gravity Droplets, after the droplets flow to the photocuring de...

Embodiment 2

[0032] Preparation of water-soluble core material pop-up beads with a size of 1.5mm

[0033] The outer diameter of the tip of the inner tube (a) is 1.15mm, the inner diameter of the tip of the inner tube (b) is 1.85mm, the distance between the two tips is 2-2.5mm, the inner diameter of the non-tip part of the two inner tubes is 2.25mm, the outer diameter is 3mm, and the inner diameter of the outer tube (c) is 3.13mm mm. Inner phase selects pure fragrance aqueous solution (containing 30% ethanol solution), the intermediate phase selects the epoxy acrylate resin containing 2wt.% photoinitiator I-184, and the external phase selects the water containing 1wt.% F108, and internal phase, intermediate phase and external phase at 10mL / h, 12mL / h and 140mL / h, respectively, into A, B, and C in the three-dimensional confocal emulsion generation channel 1, and generate W / O / W through the action of shear force and gravity Emulsified droplets, after the droplets flow to the photocuring device...

Embodiment 3

[0035] Preparation of water-soluble core material pop-up beads with a size of 3mm

[0036] The outer diameter of the tip of the inner tube (a) is 1.05mm, the inner diameter of the tip of the inner tube (b) is 2.12mm, the distance between the two tips is 1.5mm, the inner diameter of the non-tip part of the two inner tubes is 3.13mm, the outer diameter is 4mm, and the inner diameter of the outer tube (c) is 4.13mm. The internal phase selects perfume aqueous solution (containing 30% ethanol solution), the intermediate phase selects the aliphatic urethane acrylate resin containing 2wt.% photoinitiator I-184, and the external phase selects water containing 1wt.% PVA, and the internal phase, intermediate phase and the external phase are pumped into A, B, and C of the three-dimensional confocal emulsion generation channel 1 at 8mL / h, 12mL / h, and 130mL / h, respectively, and generate W / O / W through the action of shear force and gravity Emulsified droplets, after the droplets flow to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com