Biological fluidized bed reactor

A biological fluidized bed and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as corrosion of nozzle materials, failure of fluidized bed reactors to discharge heat smoothly, material deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

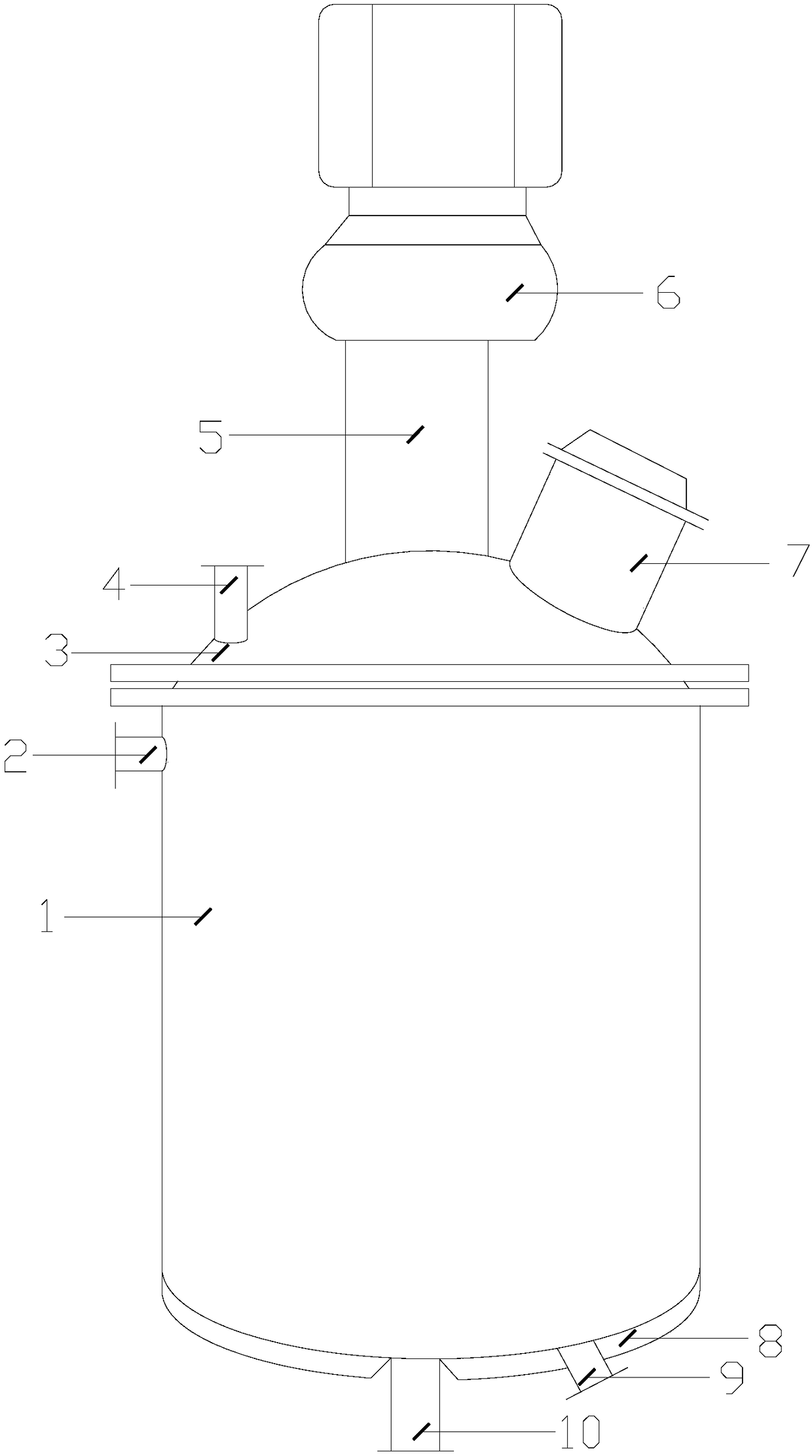

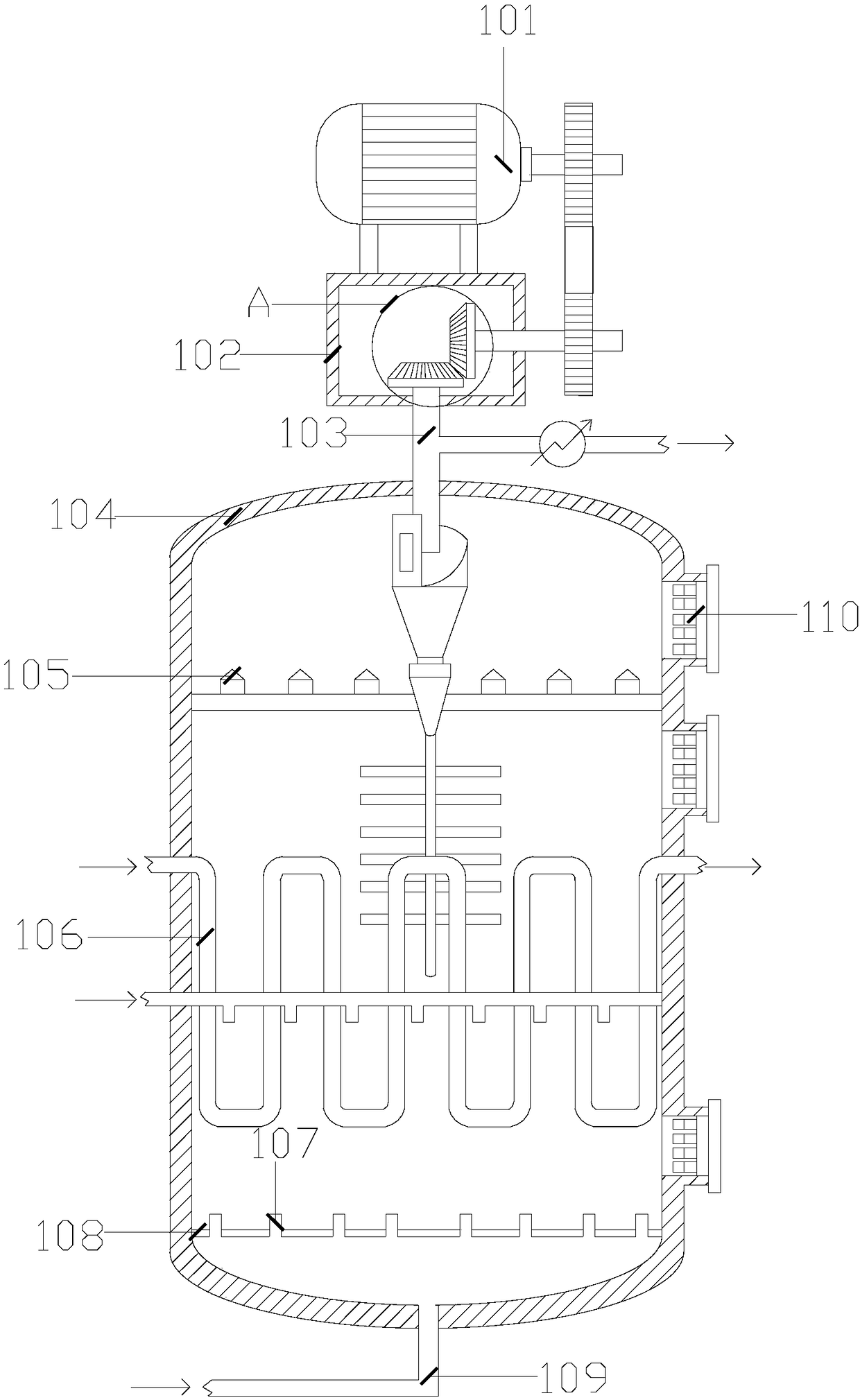

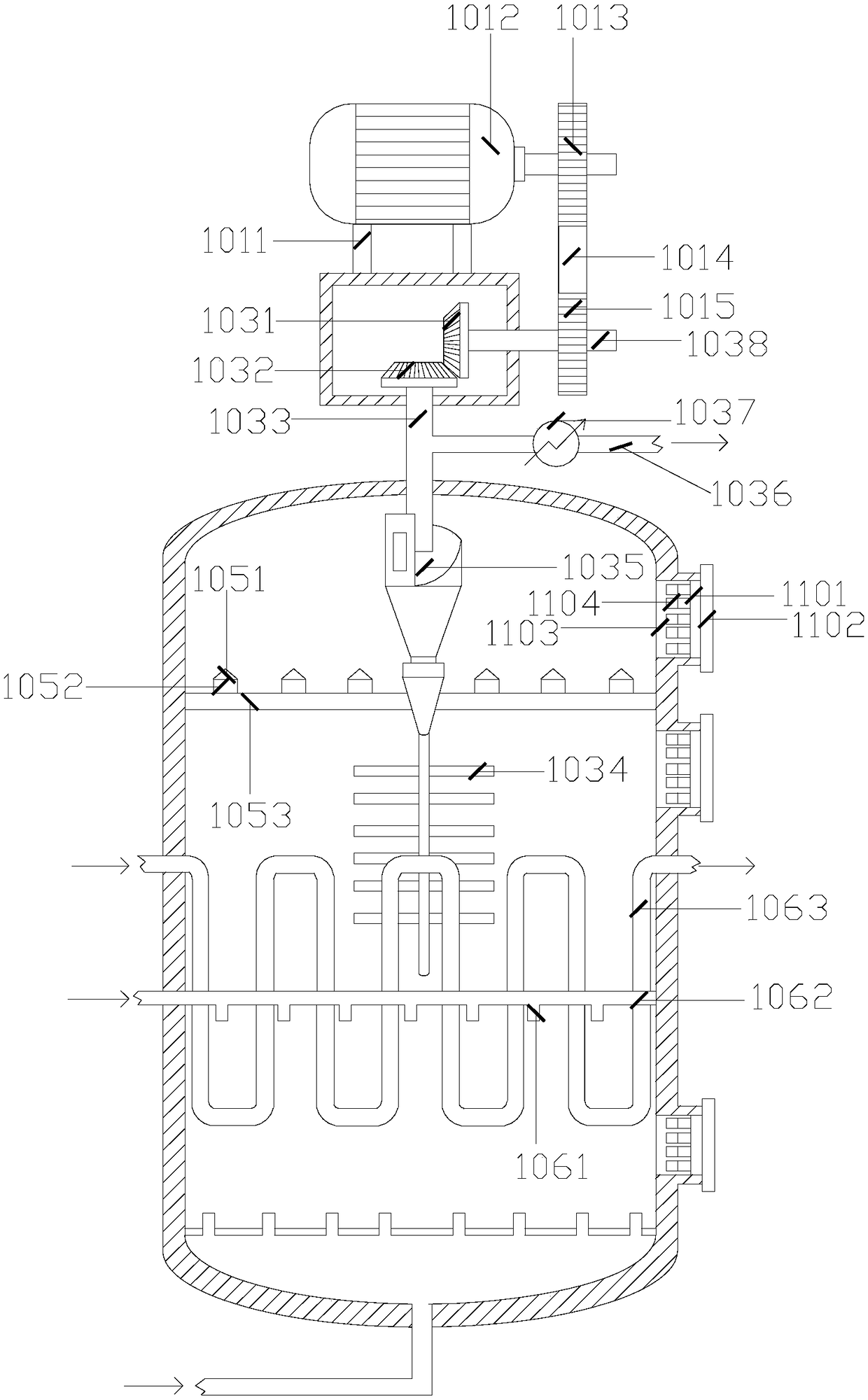

[0022] Such as Figure 1-Figure 5As shown, the present invention provides a biological fluidized bed reactor, the structure of which includes a high temperature heating mechanism 1, a first jacketed straight pipe 2, a top cover 3, a feeding pipe 4, a sealing device 5, a control device 6, and a manhole 7. The bottom of the kettle 8, the second jacket straight pipe 9, and the discharge pipe 10. The bottom of the kettle 8 is fixedly welded to the bottom of the anti-high temperature heating mechanism 1 and the two are integrally formed structures. The discharge pipe 10 is fixed It is located in the middle of the bottom end of the anti-high temperature heating mechanism 1 and the inside of the two is connected. The first jacketed straight pipe 2 and the second jacketed straight pipe 9 have the same size, and the second jacketed straight pipe 9 is fixedly embedded. On the right side of the kettle bottom 8 and in contact with the high-temperature heating mechanism 1, the first straig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap