A method for manufacturing a main girder with a hanging point pierced through an I-shaped weather-resistant steel side

A manufacturing method and technology of weathering steel, applied in bridges, buildings, etc., can solve the problems of high manufacturing precision, high welding process requirements, and complex structure of side main girders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

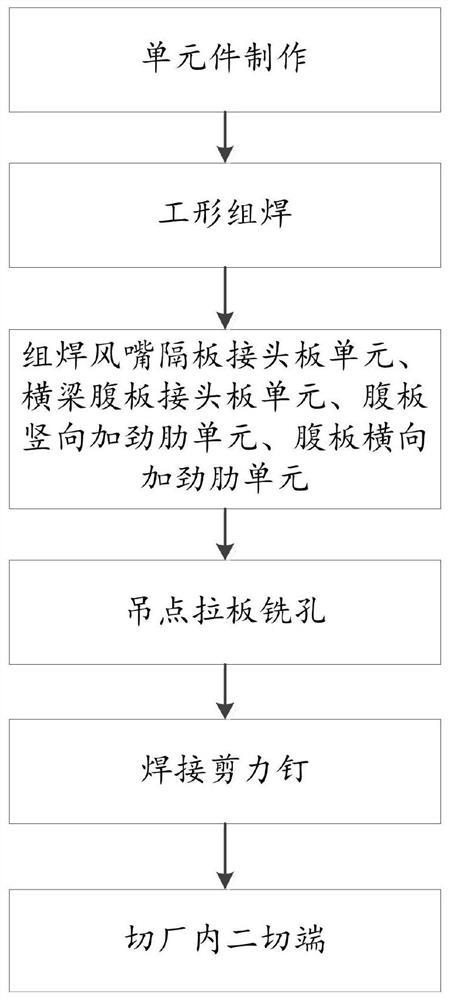

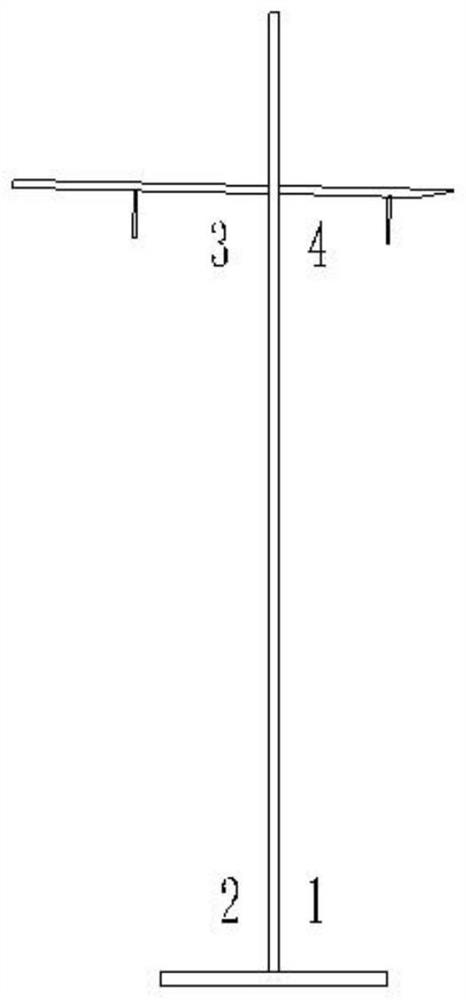

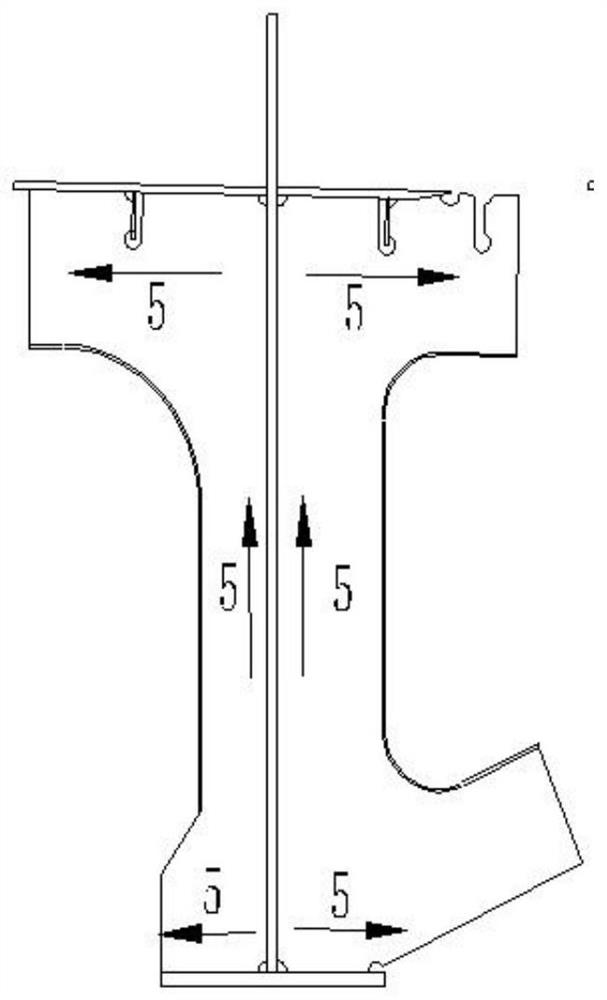

[0035] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , which is a method for manufacturing the main girder with the I-shaped weathering steel side with the hanging point pierced by the embodiment of the present invention, such as figure 1 As shown, the method includes the production of unit elements, and each unit element is manufactured according to the design requirements, and the unit elements include a web unit, an upper horizontal plate unit, a lower horizontal plate unit, a nozzle partition joint plate unit, and a beam web joint plate unit, web vertical stiffener unit, and web transverse stiffener unit; when the web unit is manufactured, the steel plate is first cut to the required size, and after cutting, it is flattened and corrected. The milling machine mills the slope, processes the groove and assembles it and welds it. After passing the weld seam flaw detection, it is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com