Efficient machining center machine

A machining center and high-efficiency technology, applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of the need to improve the processing accuracy, the low equipment utilization rate, and the machining accuracy deviation, and achieve high equipment utilization and equipment. Low cost and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

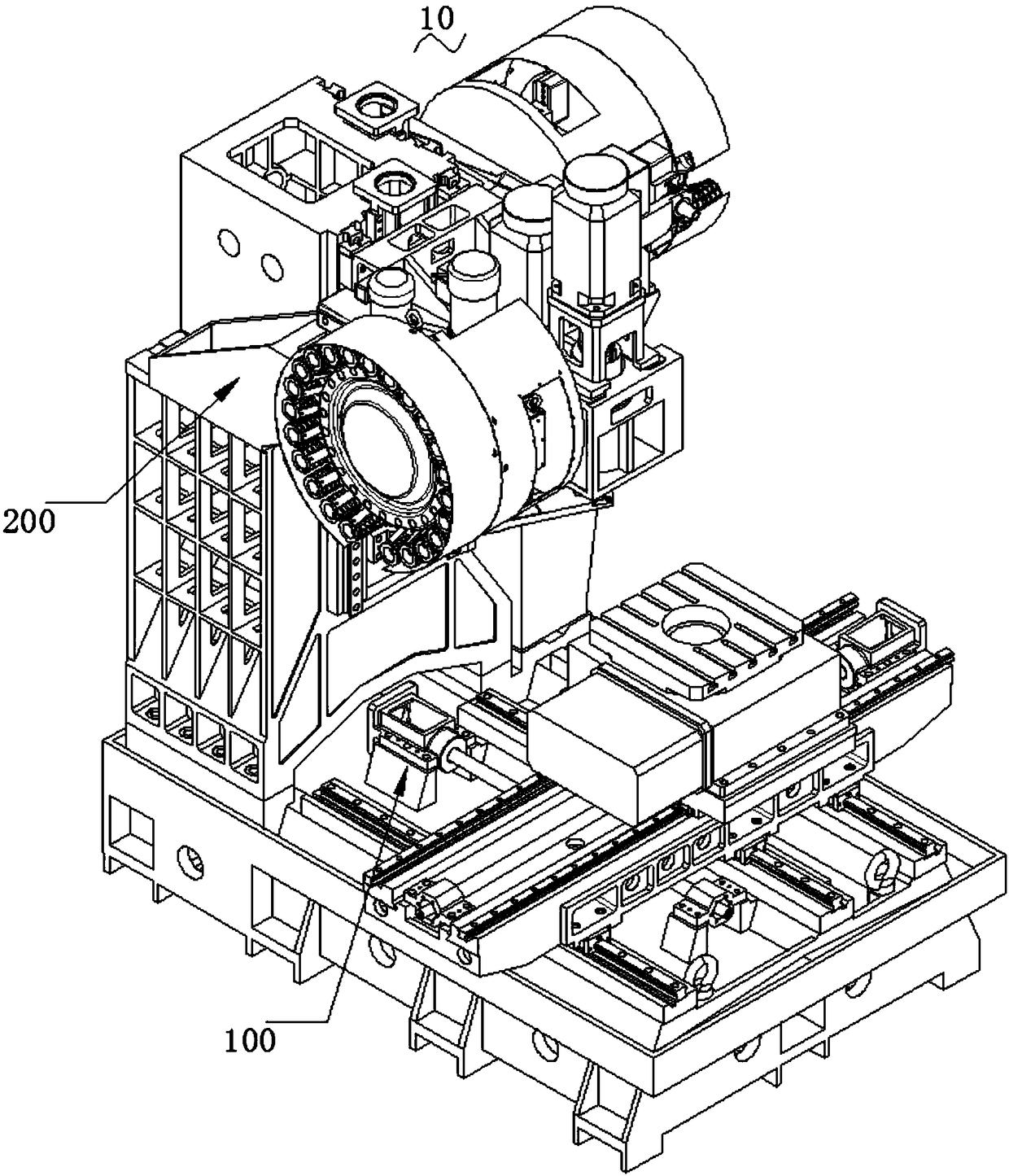

[0035] Such as Figure 1 ~ Figure 2 Shown are respectively perspective views of different viewing angles of the present invention.

[0036] The high-efficiency machining center 10 includes a workbench 100 and a processing part 200 located at one end of the workbench 100 .

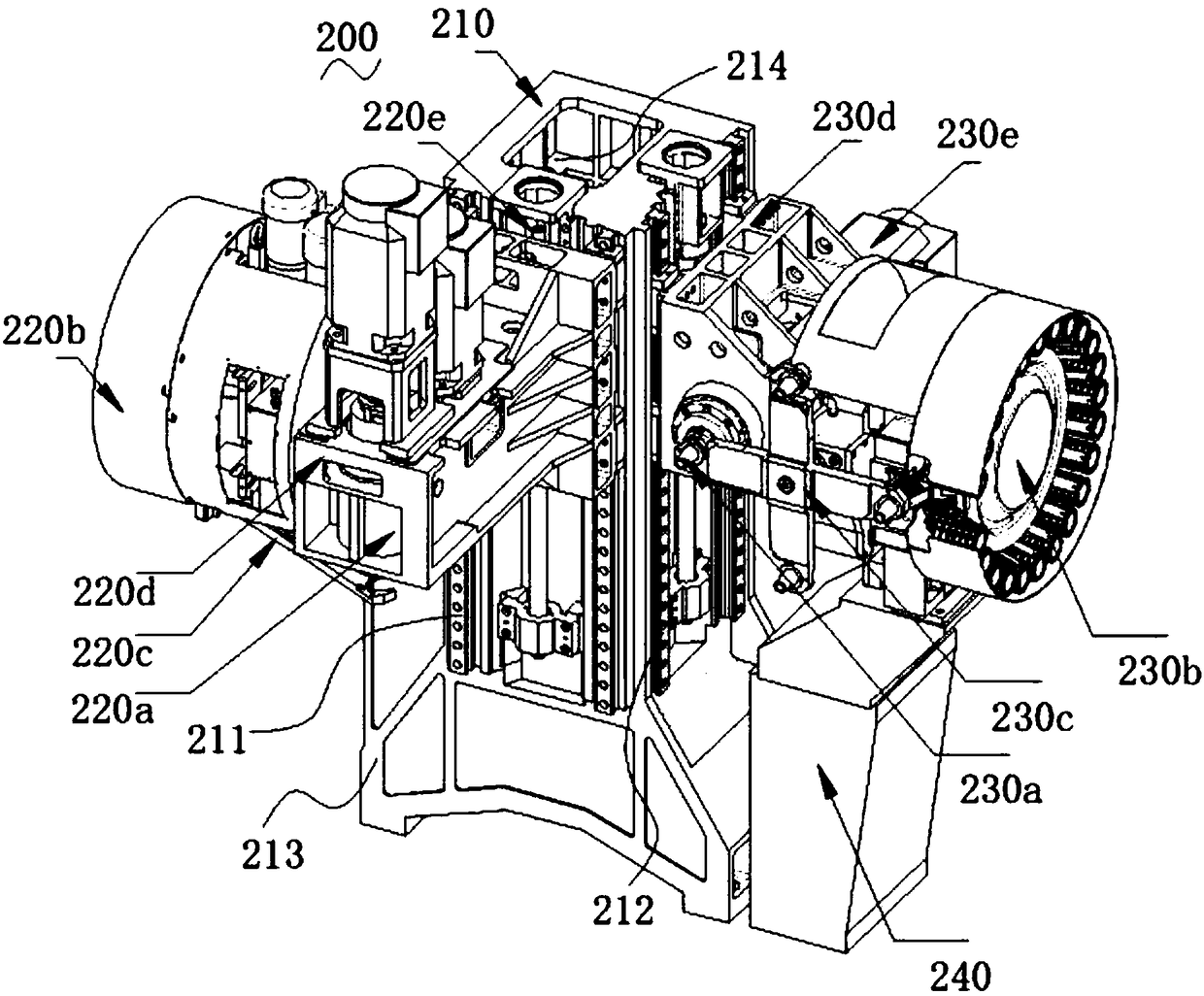

[0037] Such as Figure 3 ~ Figure 5 Shown are perspective views and front views of the processing part of the present invention at different angles of view.

[0038] The processing part 200 includes a square column 210, a first processing machine head 220a and a first tool magazine 220b slidingly arranged on one side of the square column 210, and a first tool magazine 220b connected to the first processing machine head 220a and the first tool magazine 220b. The knife arm 220c is slidably arranged on one side of the square column 210 and is located on the second processing head 230a and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com