Cleaning and descaling device

A technology for cleaning and descaling and cleaning surfaces, applied in the field of descaling, can solve the problems of low descaling efficiency, large volume, hidden dangers to user safety, etc., and achieve the effects of saving electrolysis energy consumption, simple device structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

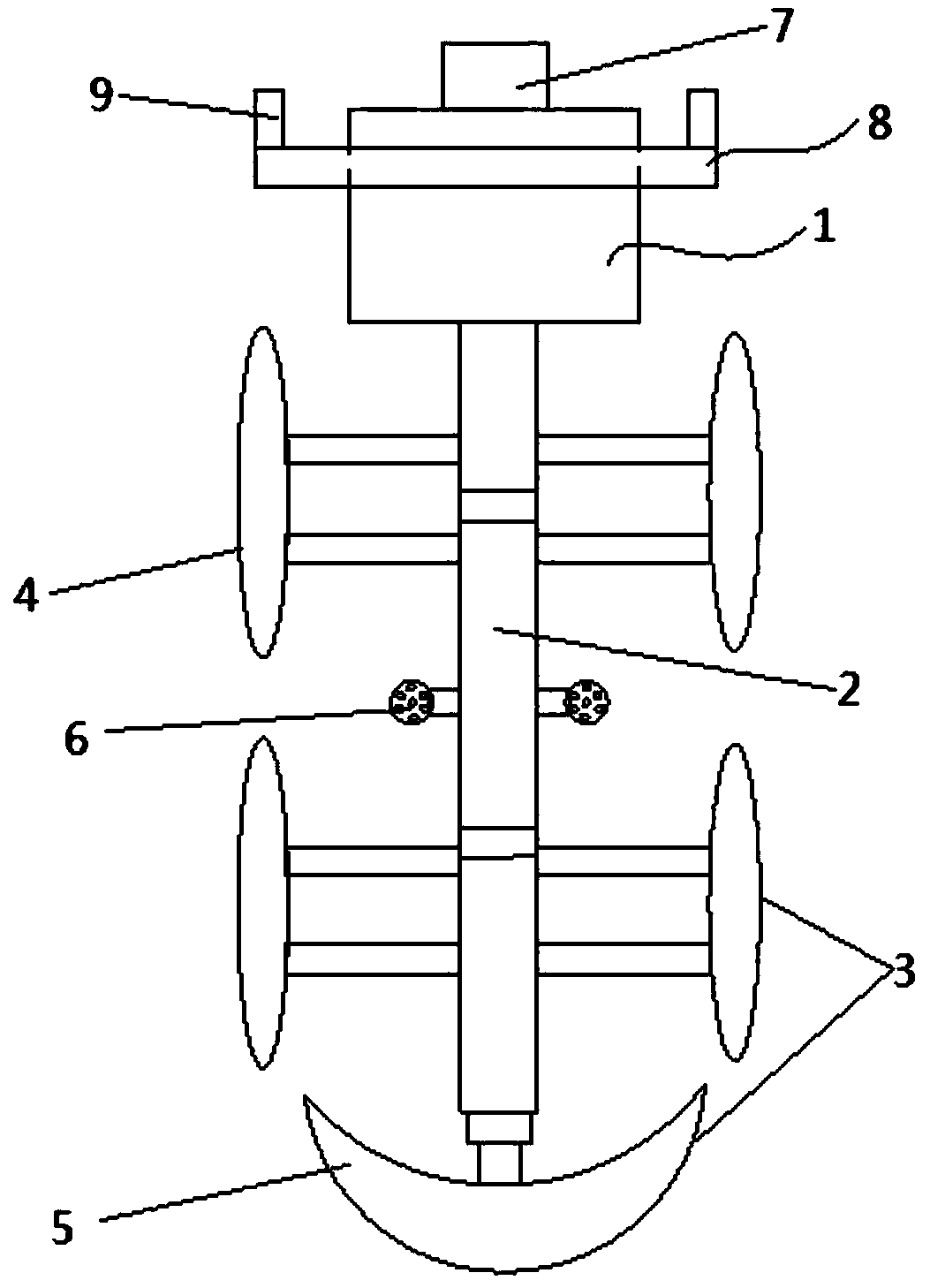

[0030] Such as figure 1As shown, a cleaning and descaling device is disclosed in this embodiment, which includes a descaling drive device 1, a descaling drive rod 2 and a cleaning mechanism 3, and is characterized in that: the descaling drive device 1 is provided with an acidic electrolyzed water generator One end of the descaling driving rod 2 is connected with the motor in the descaling driving device 1, the descaling driving rod 2 can rotate, and the rod body of the descaling driving rod 2 is a telescopic structure; the cleaning mechanism 3 includes a side cleaning surface 4 and a bottom cleaning Surface 5, side cleaning surface 4 has at least two, and side cleaning surface 4 is arranged on the bar body side of descaling driving rod 2, and side cleaning surface 4 and descaling driving rod 2 joints are provided with side spring mechanism, bottom cleaning surface 5 and The descaling driving rod 2 is connected to one end away from the descaling driving device 1 , and a bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com