Acrylic polyurethane paint and preparation method thereof

A technology of acrylic polyurethane and hydroxyacrylic acid, applied in the field of coatings, can solve the problems of high VOC emissions, low volume solid content, poor weather resistance, etc., achieve low VOC content, high volume solid content, and improve anti-corrosion performance

Inactive Publication Date: 2018-08-10

无锡市太湖防腐材料有限公司

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The invention provides an acrylic polyurethane paint and a preparation method thereof to solve the problems of poor corrosion resistance, poor weather resistance, low volume solid content and high VOC emission of common acrylic polyurethane topcoats in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

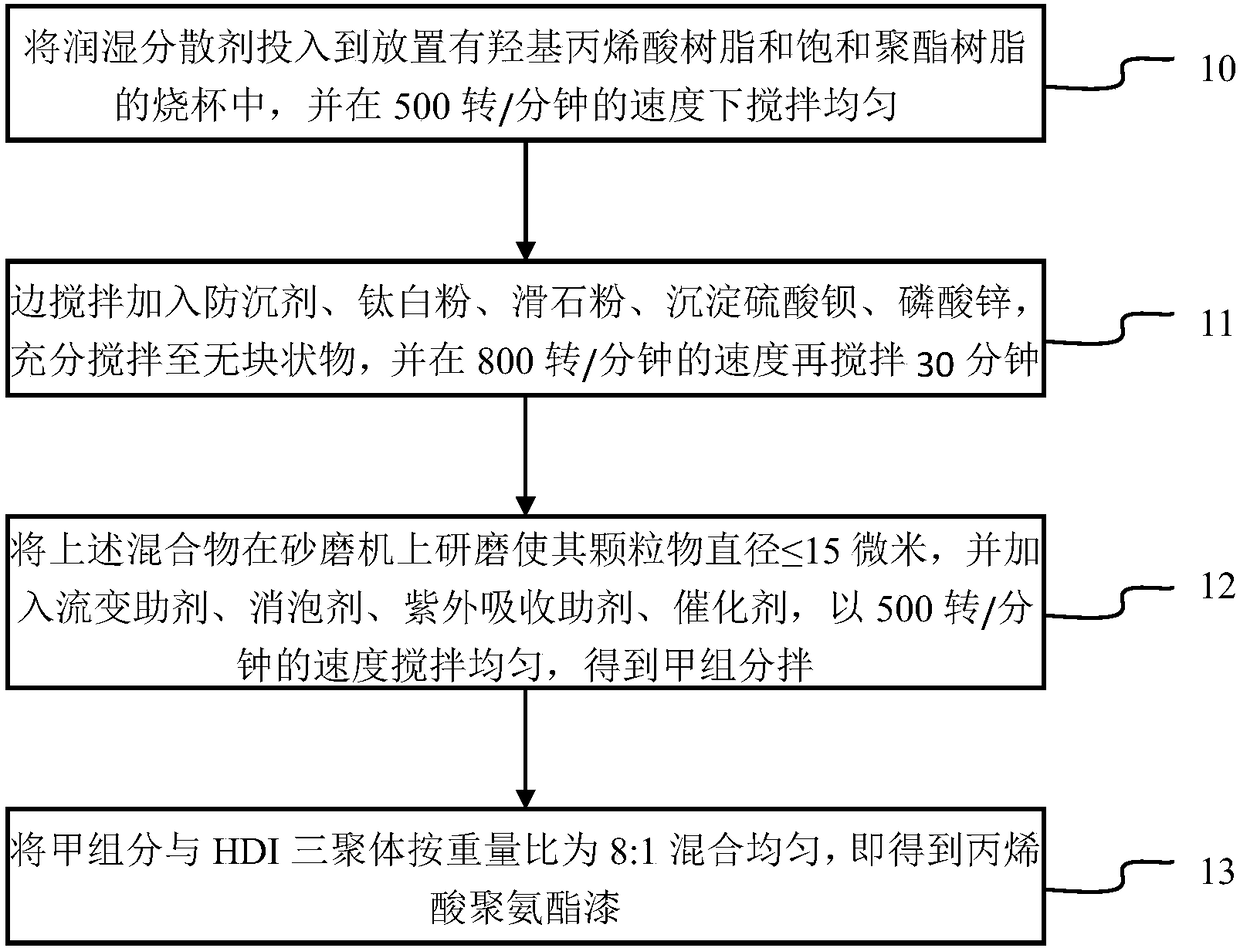

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

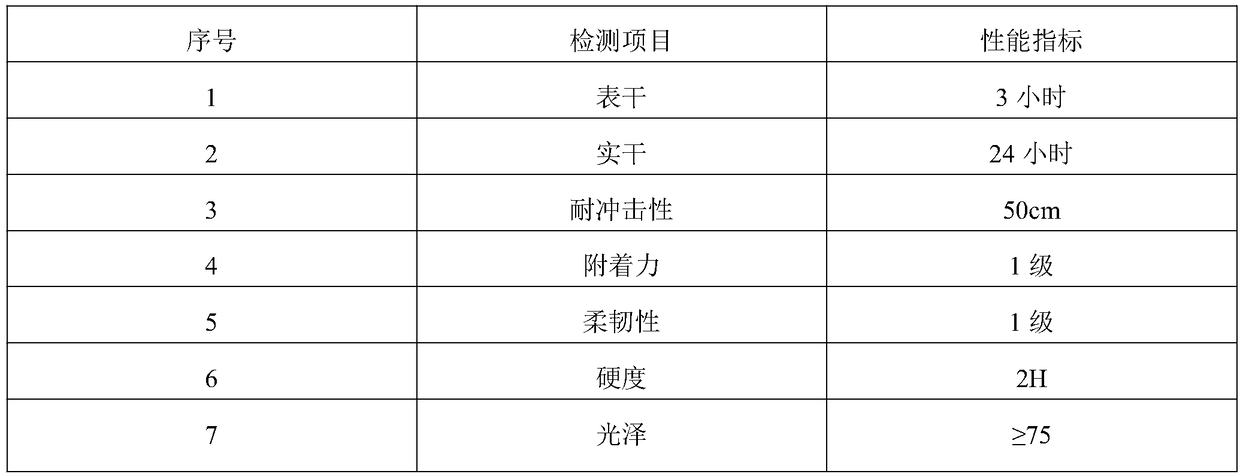

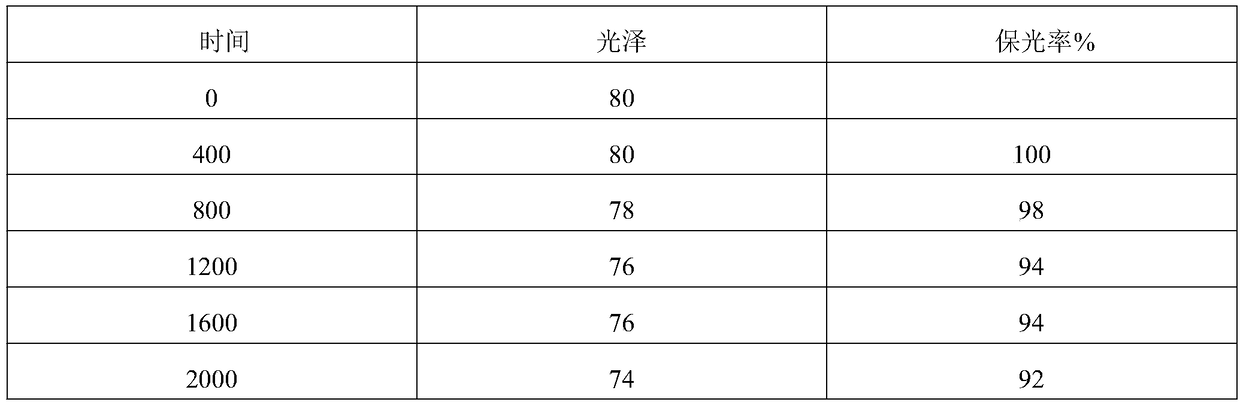

The invention provides an acrylic polyurethane paint and a preparation method thereof. The acrylic polyurethane paint is composed of a component A and a component B. The component A is composed of thefollowing components by weight percentage: 20-25% of hydroxyl acrylic resin (75% solid content), 10-15% of saturated polyester resin (80% solid content), 18-25% of rutile titanium dioxide, 15-20% oftalc powder, 15-20% of precipitated barium sulfate, 10-15% of zinc phosphate, 0.1-0.5% of a wetting dispersant, 0.5-1% of an anti-sedimentation agent, 0.5-1% of a rheological assistant, 0.1-0.5% of anultraviolet absorbent, 0.1-0.5% of a defoamer, 5-10% of a solvent, and 0.01-0.05% of a catalyst. The component B is an HDI trimer. And the weight ratio of the component A to the component B is 8:1. The invention solves the problems of poor corrosion resistance, poor weatherability, low volume solid content and high VOC emission of common acrylic polyurethane finish paint in the prior art.

Description

technical field [0001] The invention relates to the field of coatings, in particular to an acrylic polyurethane paint and a preparation method thereof. Background technique [0002] With the rapid development of my country's industrial construction and marine construction, the anti-corrosion requirements for steel facilities are getting higher and higher. The representative supporting system for heavy-duty anti-corrosion coatings is epoxy zinc-rich primer-epoxy mica iron intermediate paint-acrylic polyurethane topcoat. Traditional solvent-based epoxy zinc-rich primer, epoxy miracic iron intermediate paint and acrylic polyurethane topcoat have the disadvantages of low volume solid content, high VOC emission, and the total film thickness of spraying three layers of paint can reach 200 microns. At the same time, In the field of anti-corrosion equipment, metal surface, large-scale bridges, heavy-duty anti-corrosion projects, etc., the weather resistance, salt spray resistance, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D175/04C09D5/08C09D7/48C09D7/61

CPCC09D175/04C08K2003/2241C08K2003/3045C08L2201/08C09D5/084C09D7/48C09D7/61C08L91/06C08L91/00C08L83/04C08K3/22C08K3/34C08K3/30C08K3/00

Inventor 刘嘉东王荣

Owner 无锡市太湖防腐材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com