High performance glass fiber tape adhesive and preparation method thereof

A glass fiber tape, high-performance technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of tape tensile strength reduction, adhesion performance decline, and applicability reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

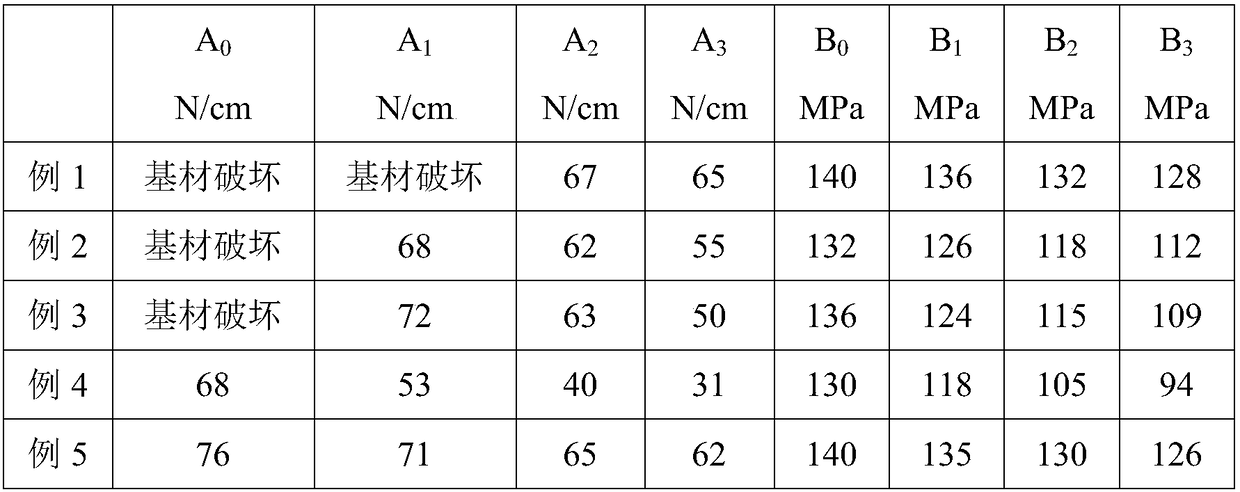

Examples

Embodiment 1

[0042] High-performance fiberglass adhesive tape, its preparation raw materials include 100 parts of polyisobutylene, 20 parts of calcium carbonate, 10 parts of soft clay, 12.5 parts of terpene resin, 12.5 parts of terpene phenol resin, N-cyclohexyl-N 0.6 parts of '-phenyl-p-phenylenediamine, 0.2 parts of hydroquinone dibenzyl ether, and 15 parts of vinyl glucopyranoside. The number average molecular weight of the polyisobutylene is 12000.

[0043] The preparation method of high-performance glass fiber tape glue, mix 100 parts of polyisobutylene and 15 parts of vinyl glucopyranoside in a mixer, heat to 155 ° C, then add 0.5 parts of lauroyl peroxide, continue stirring for 4 hours, add carbonic acid 20 parts of calcium, 10 parts of soft clay, continue to stir for 10 hours, then add 12.5 parts of terpene resin and 12.5 parts of terpene phenol resin, stir for 30 minutes, and extrude to obtain the product.

[0044] First let the glass fiber base material undergo low-temperature p...

Embodiment 2

[0046] High-performance fiberglass adhesive tape, its preparation raw materials include 100 parts of polyisobutylene, 20 parts of calcium carbonate, 10 parts of soft clay, 12.5 parts of terpene resin, 12.5 parts of terpene phenol resin, N-cyclohexyl-N 0.6 parts of '-phenyl-p-phenylenediamine, 0.2 parts of hydroquinone dibenzyl ether, and 15 parts of vinyl glucopyranoside. The number average molecular weight of the polyisobutylene is 5000.

[0047] The preparation method of high-performance glass fiber tape glue, mix 100 parts of polyisobutylene and 15 parts of vinyl glucopyranoside in a mixer, heat to 155 ° C, then add 0.5 parts of lauroyl peroxide, continue stirring for 4 hours, add carbonic acid 20 parts of calcium, 10 parts of soft clay, continue to stir for 10 hours, then add 12.5 parts of terpene resin and 12.5 parts of terpene phenol resin, stir for 30 minutes, and extrude to obtain the product.

[0048] First let the glass fiber base material undergo low-temperature pl...

Embodiment 3

[0050] High-performance fiberglass adhesive tape, its preparation raw materials include 100 parts of polyisobutylene, 20 parts of calcium carbonate, 10 parts of soft clay, 12.5 parts of terpene resin, 12.5 parts of terpene phenol resin, N-cyclohexyl-N 0.6 parts of '-phenyl-p-phenylenediamine, 0.2 parts of hydroquinone dibenzyl ether, and 15 parts of vinyl glucopyranoside. The number average molecular weight of the polyisobutylene is 25000.

[0051] The preparation method of high-performance glass fiber tape glue, mix 100 parts of polyisobutylene and 15 parts of vinyl glucopyranoside in a mixer, heat to 155 ° C, then add 0.5 parts of lauroyl peroxide, continue stirring for 4 hours, add carbonic acid 20 parts of calcium, 10 parts of soft clay, continue to stir for 10 hours, then add 12.5 parts of terpene resin and 12.5 parts of terpene phenol resin, stir for 30 minutes, and extrude to obtain the product.

[0052] First let the glass fiber base material undergo low-temperature p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap