Horizontal well drilling fluid without being mixed with oil and preparation method and application of horizontal well drilling fluid

A technology for horizontal wells and drilling fluids, applied in the field of petroleum drilling fluids, which can solve problems such as increasing the difficulty of drilling construction technology, environmental pollution of crude oil, and difficulties in environmental protection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

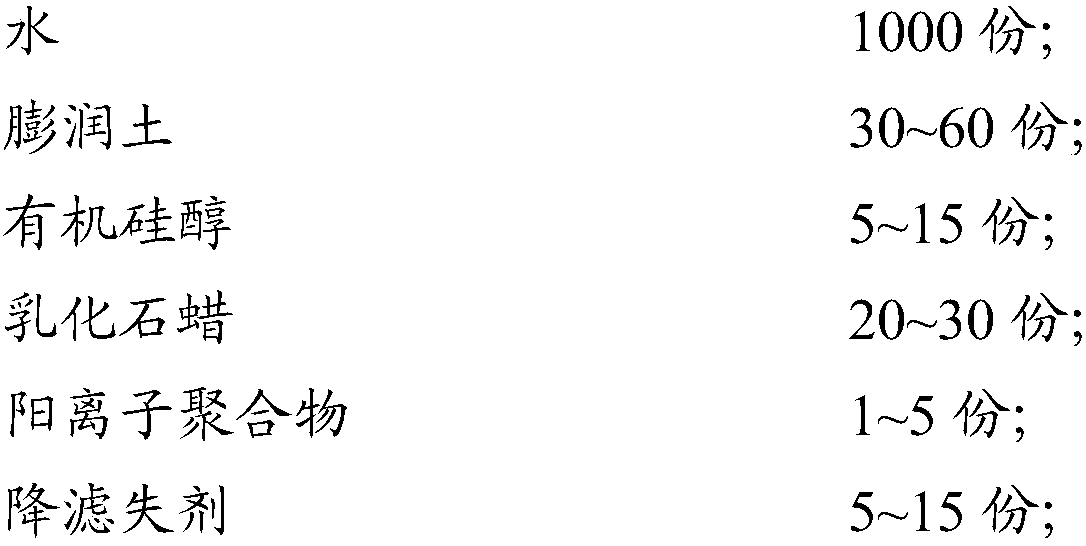

Embodiment 1

[0046] Weigh the remaining components according to the mass percentage of the remaining components in water, including 5% bentonite, 1.0% organosilicone inhibitor, 2% emulsified paraffin, 0.3% cationic emulsion polymer, and 0.5% cationic polymer fluid loss control agent. %, polyacrylonitrile ammonium salt 1.0%, sulfomethylated phenolic resin 1.5% and sulfonated lignite 1.6% to prepare drilling fluid.

[0047] Table 1 shows the basic properties of the horizontal well drilling fluid prepared in Example 1 at room temperature and after 16 hours of aging treatment at 150°C.

[0048] The normal temperature and aging treatment basic properties of the oil-immiscible horizontal well drilling fluid obtained in Table 1 Example 1

[0049] class performance

Room temperature performance

Performance after 150℃ / 16h high temperature aging

Apparent viscosity AV(mpa.s)

25~55

20~50

Dynamic shear force YP(pa)

10~20

5~15

API filtration loss FL(mL) ...

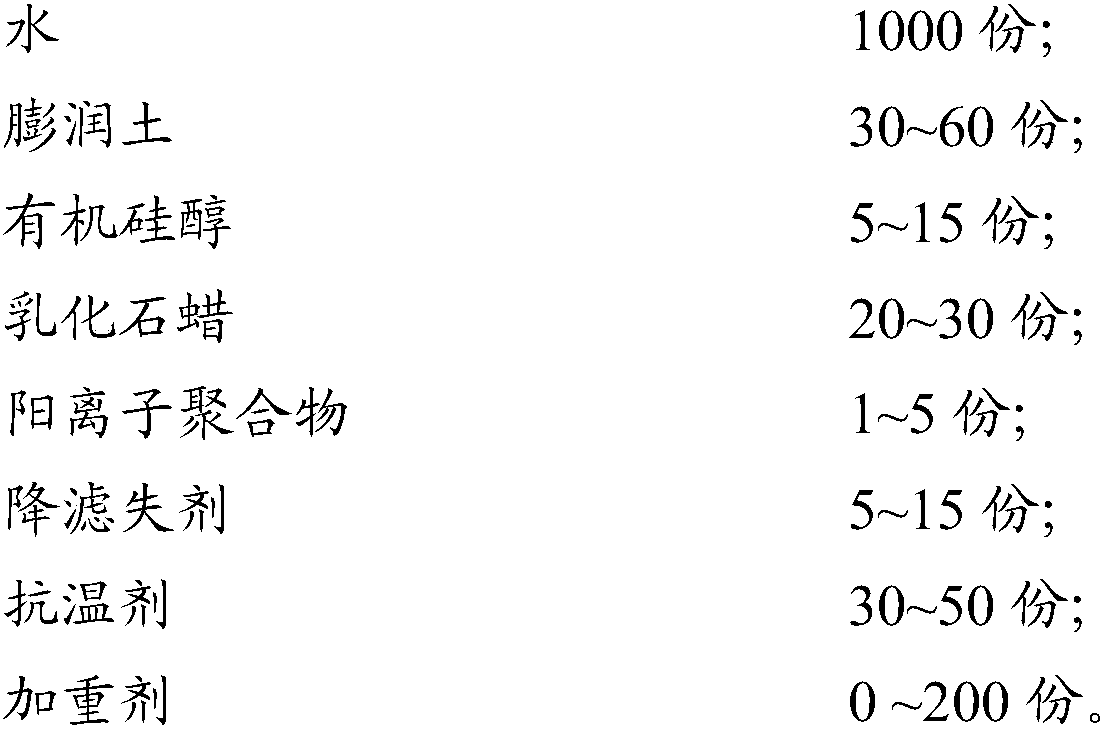

Embodiment 2

[0077] The horizontal well drilling fluid formula is: 50 parts of bentonite; 10 parts of organosilicone inhibitor; 20 parts of emulsified paraffin; 3 parts of cationic emulsion polymer; 5 parts of cationic polymer fluid loss reducer; 10 parts of polyacrylonitrile amine salt; 15 parts of methylated phenolic resin; 20 parts of sulfonated lignite; 0 parts of weighting agent; 1000 parts of water.

Embodiment 3

[0093] Weigh the remaining components according to the mass percentage of the remaining components in water, and prepare the drilling fluid, wherein, 5% bentonite, 2% RHJ-1, 0.3% DS-301, 1% DS-302, 1.5% NH4-HPAN, 2% SMP, 2% SMC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com