Steam condensing device of granulating slag pit as well as gas collecting cover thereof and using method thereof

A technology of steam condensation and gas collecting hood, which is applied in chemical instruments and methods, cleaning methods and utensils, recycling technology, etc., can solve problems such as unfavorable slag removal operations, fog hindering operations, and polluting the environment, so as to reduce environmental pollution, The effect of less water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

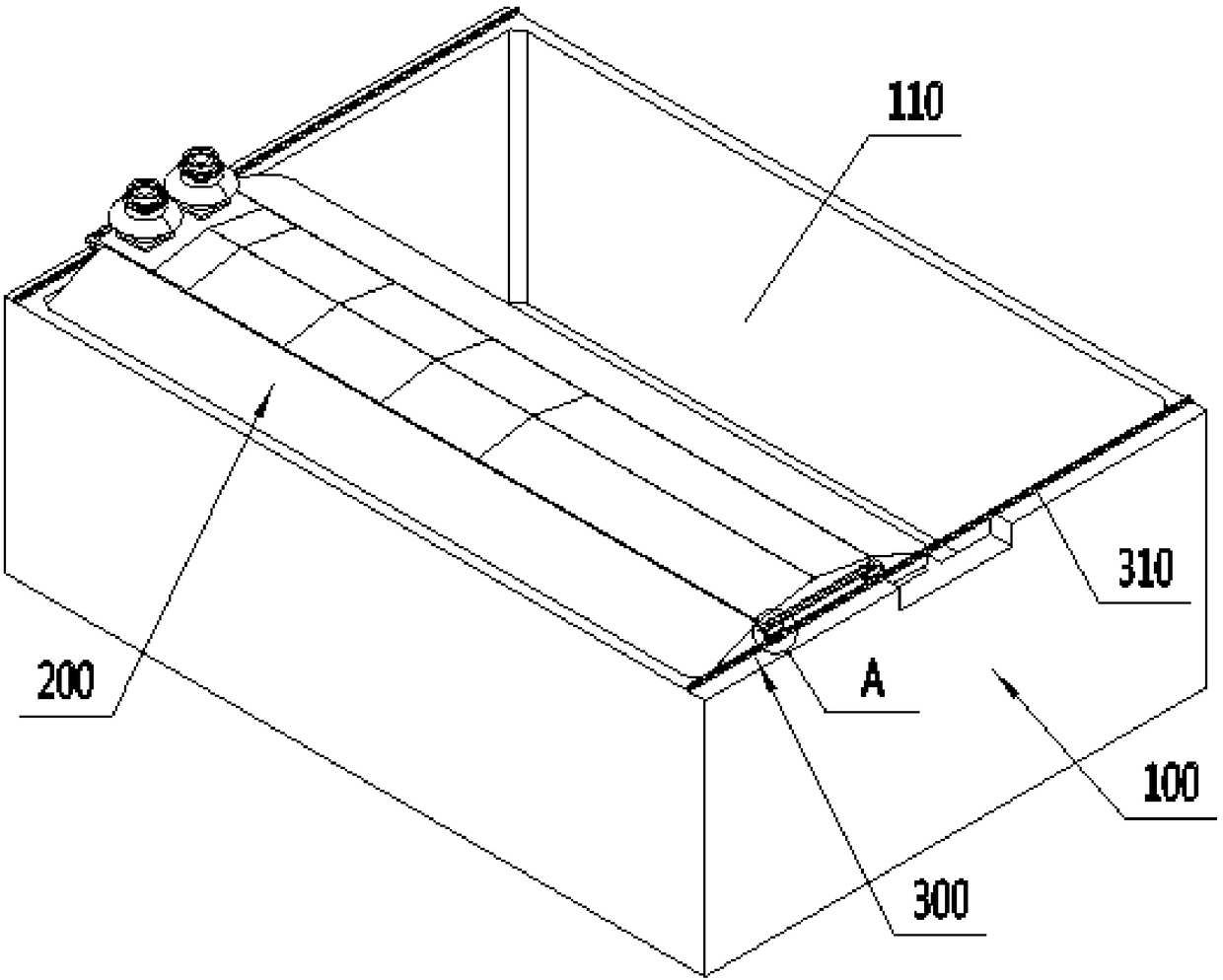

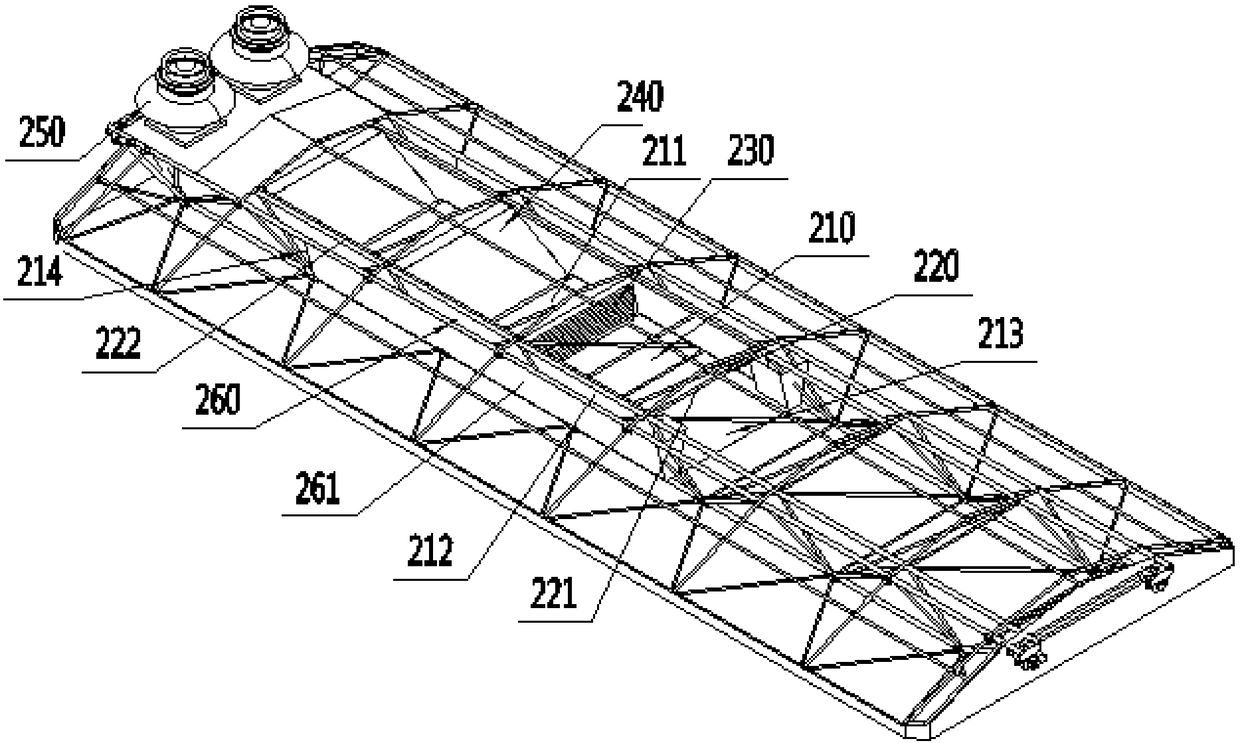

[0037] Such as figure 1 As shown, this embodiment provides a steam condensing device for a slag pool, which is mainly used in blast furnace slag precipitation treatment to obtain slag. It is different from the traditional open operation form of a slag pool. The device is innovatively designed to collect gas The cover 200 covers the water slag pool to block the generation of mist, thereby improving the operating environment. The structure and principle of the device will be described in detail below.

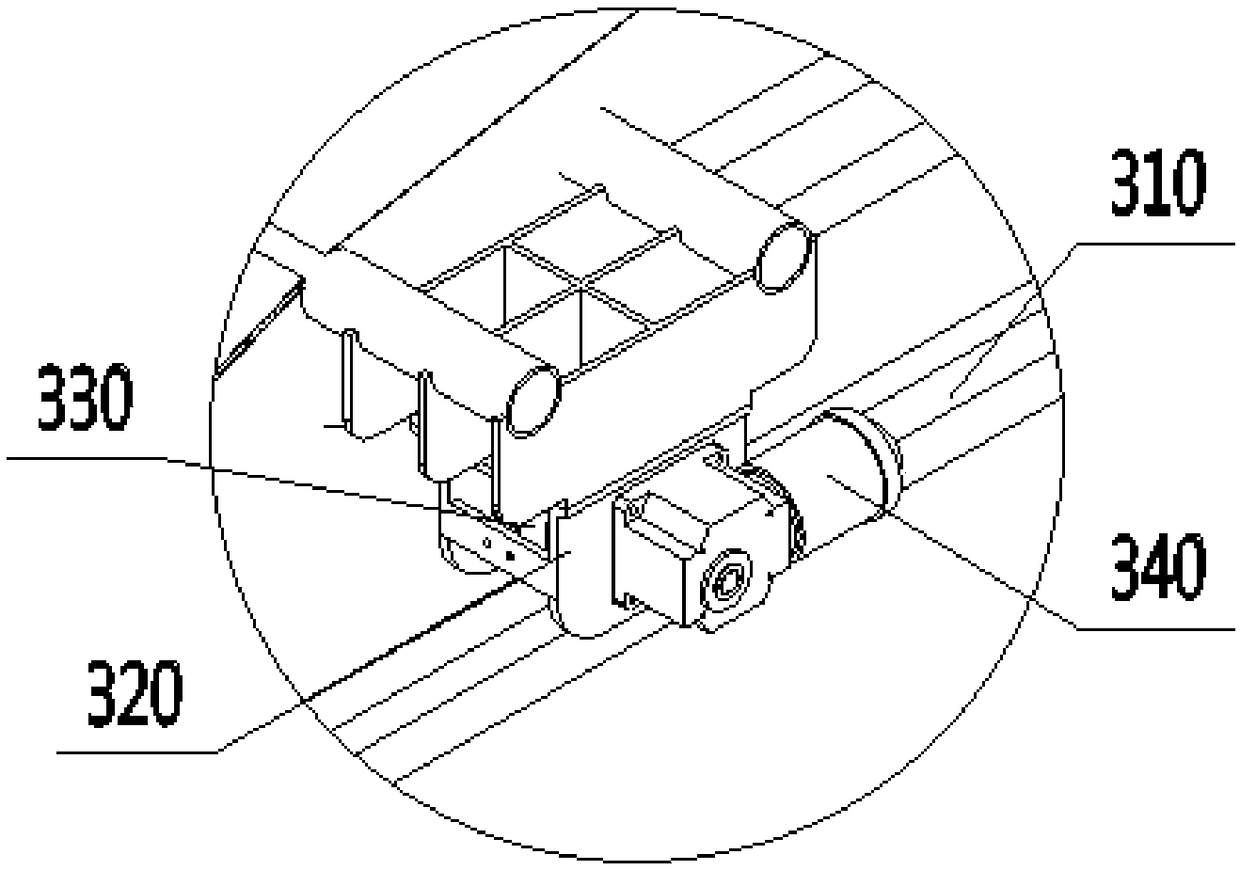

[0038]The water slag pool steam condensing device mainly includes a pool body 100 and a gas collecting hood 200 . Among them, the tank body 100 is used to receive blast furnace slag and process it. It is equipped with a slag tank 110. The number of slag tanks 110 can be set according to the needs, and it can be one or multiple side by side. Here, two slag tanks are selected to be designed. The tanks 110 can alternately process water slag, and when one is processing water slag, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com