Blast furnace furnace-front molten iron titanium removing method

A technology for removing titanium and molten iron, which is applied in the field of ironmaking, can solve the problems of reducing cleanliness, low titanium content, and reducing the electromagnetic properties of finished products, and achieves the effect of strong site adaptability and high efficiency of titanium removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

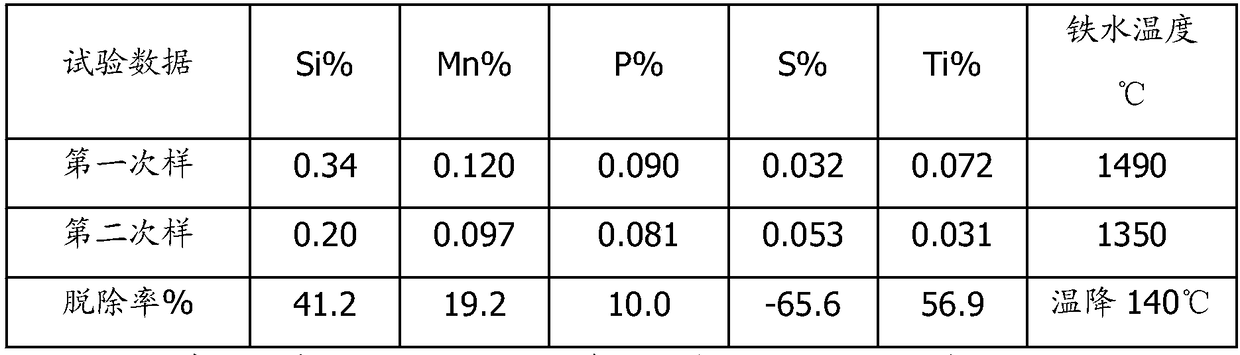

Embodiment 1

[0024] In this embodiment, the original titanium content in the molten iron is not high (0.072%), and no titanium is added to protect the furnace; the method for removing titanium from the molten iron in front of the blast furnace in the embodiment of the present invention includes:

[0025] Prepare the detitanium agent according to the mass percentage of 1% of the ton of iron, take the first iron sample to check the composition from the replacement of the torpedo tank, and then start spraying the detitanium agent, spray it into the sampling port of the iron trench according to the flow rate of 1kg / s, and spray about After blowing for 35 minutes, the torpedo tank is connected with a can of molten iron about 210t, transported to the desulfurization station, the slag is removed, and the second iron sample is taken.

[0026] The above-mentioned detitanium removal agent composition weight percent comprises: Fe 2 o 3 75%, S 0.04%, water content 0.3%, CaO 11.66%, SiO 2 7%, MgO 3%,...

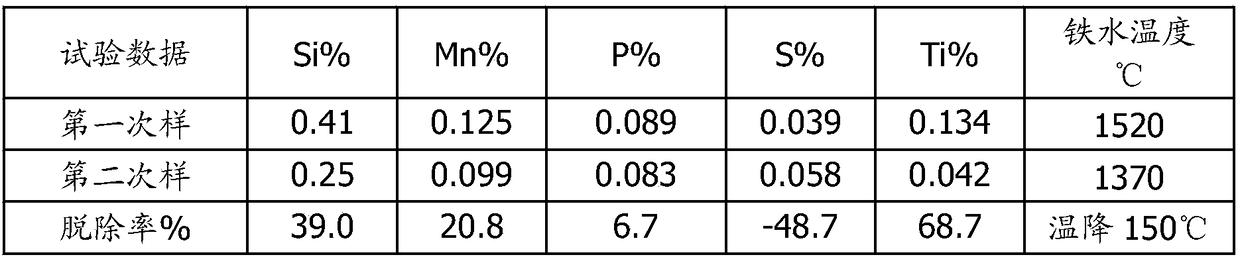

Embodiment 2

[0033] In this embodiment, the content of primary titanium in the molten iron is high (0.134%), and titanium is added to protect the furnace; the method for removing titanium from the molten iron in front of the blast furnace in the embodiment of the present invention includes:

[0034] Prepare the detitanium removal agent at 2% of the ton of iron by mass percentage, take the first iron sample to inspect the composition from the replacement of the torpedo tank, and then start spraying the detitanium agent, spray it into the sampling port of the iron trench according to the flow rate of 3kg / s, and spray about After blowing for 15 minutes, the torpedo tank received a can of molten iron about 210t, transported to the desulfurization station, slag was removed, and the second iron sample was taken.

[0035] The above-mentioned detitanium removal agent composition weight percent comprises: Fe 2 o 3 80%, S 0.02%, water content 0.2%, CaO 10%, SiO 2 5%, MgO 2.78%, Al 2 o 3 2%.

[...

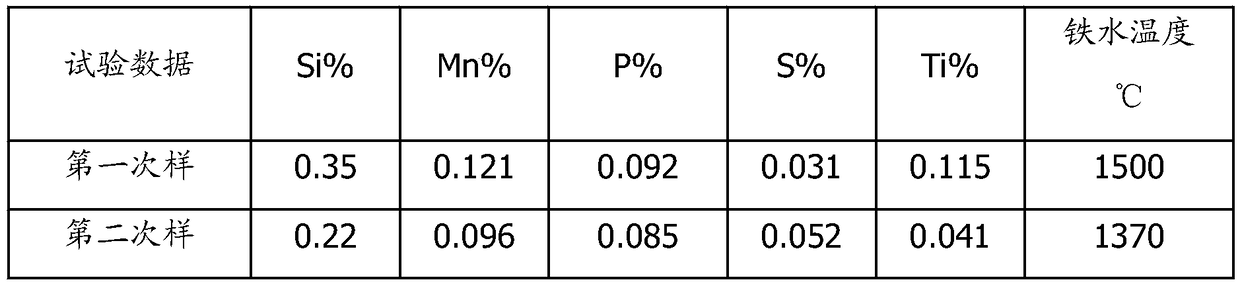

Embodiment 3

[0041] In this embodiment, the original titanium content in the molten iron is high (0.115%), and no titanium is added to protect the furnace; the method for removing titanium from the molten iron in front of the blast furnace in the embodiment of the present invention includes:

[0042] Prepare detitanium removal agent at 2% of ton of iron by mass percentage, take the first iron sample to check the composition from the change of torpedo tank, then start to spray the detitanium agent, spray it into the iron ditch sampling port according to the flow rate of 2kg / s, about spray After blowing for 20 minutes, the torpedo tank is connected with a tank of molten iron about 210t, transported to the desulfurization station, slag is removed, and the second iron sample is taken.

[0043] The above-mentioned detitanium removal agent composition weight percent comprises: Fe 2 o 3 85%, S is 0.01%, water content is 0.1%, CaO6%, SiO 2 4.89%, MgO 2%, Al 2 o 3 2%.

[0044] The particle siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com