Patents

Literature

42 results about "Kinetics reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of reaction kinetics. : a branch of chemistry that deals with the rate of chemical reactions, with factors influencing such rates, and with applications of rate studies to elucidate the mechanism of reactions — compare order of a reaction.

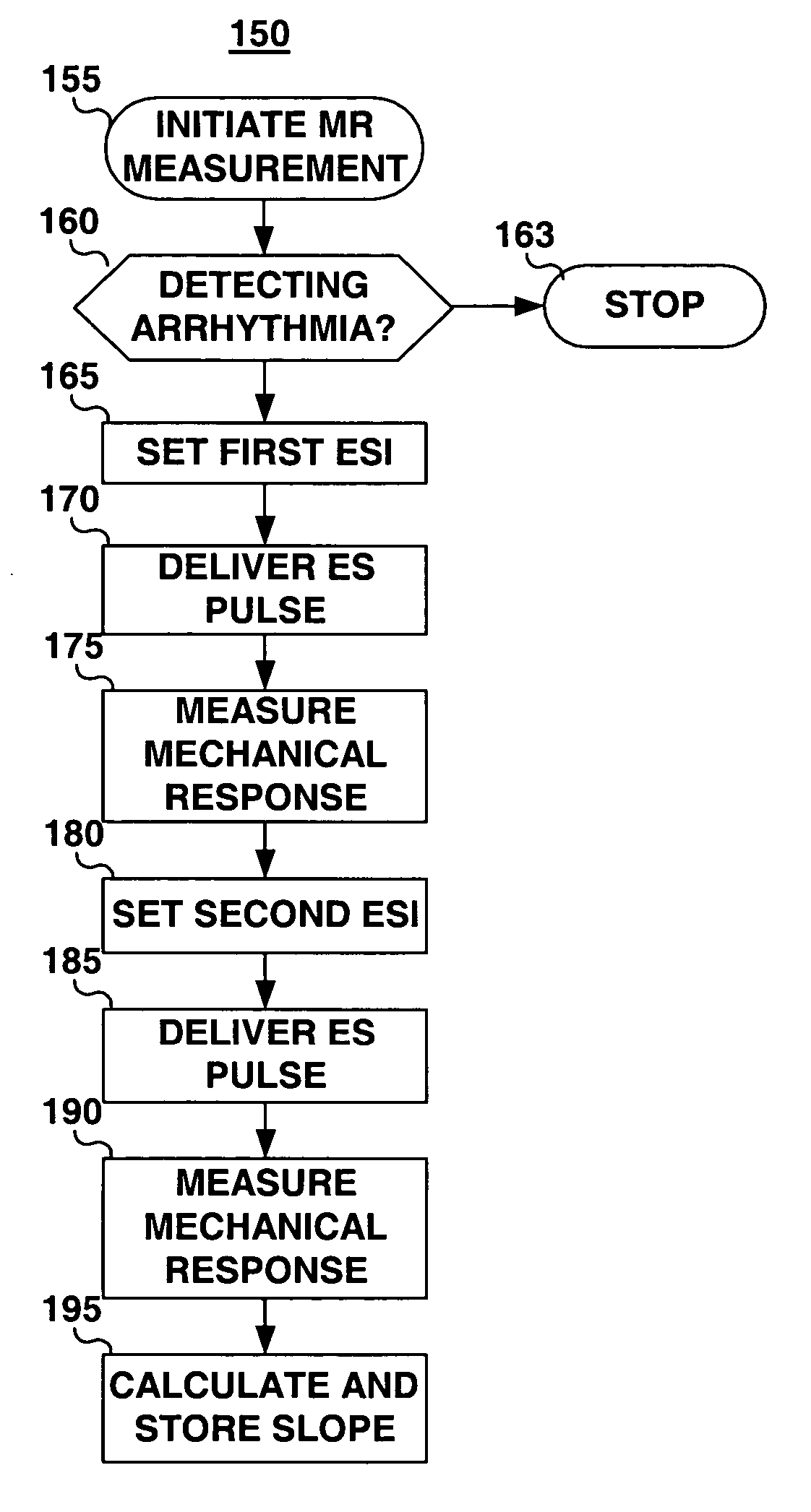

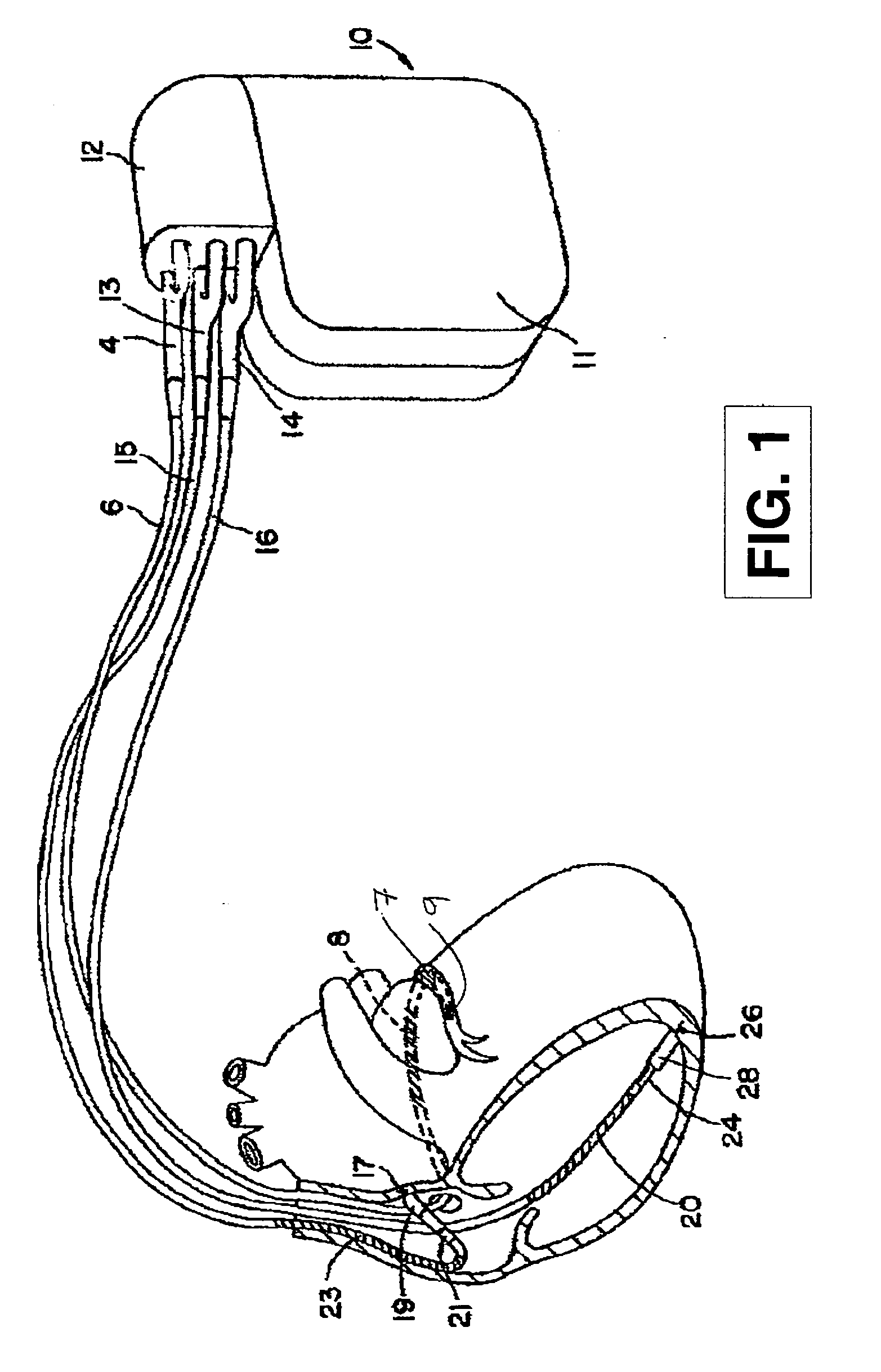

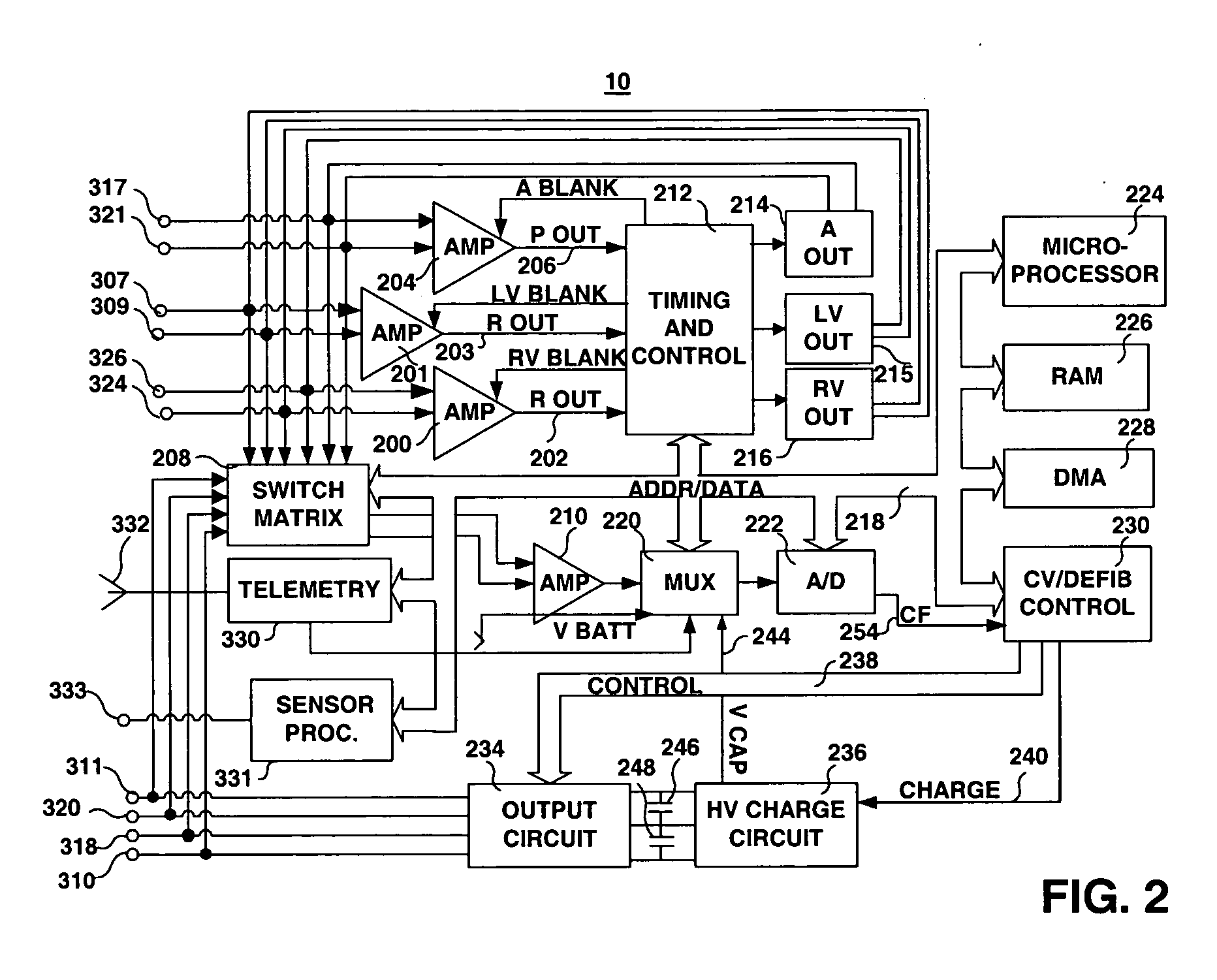

Use of mechanical restitution to predict hemodynamic response to a rapid ventricular rhythm

An implantable cardiac stimulation device and associated method for predicting the hemodynamic response to a rapid heart rhythm. The system includes an implantable cardiac stimulation device and associated sensors of electrical and mechanical heart function. The associated method includes measuring a mechanical restitution (MR) parameter or surrogate thereof, performing a comparative analysis of the MR parameter, and predicting an unstable or stable hemodynamic response to a rapid heart rate based on the comparative analysis. If an unstable hemodynamic response to a rapid rhythm is predicted, a more aggressive menu of arrhythmia therapies may be programmed to treat tachycardia. If a stable hemodynamic response is predicted, a less aggressive menu of therapies may be programmed to treat tachycardia.

Owner:MEDTRONIC INC

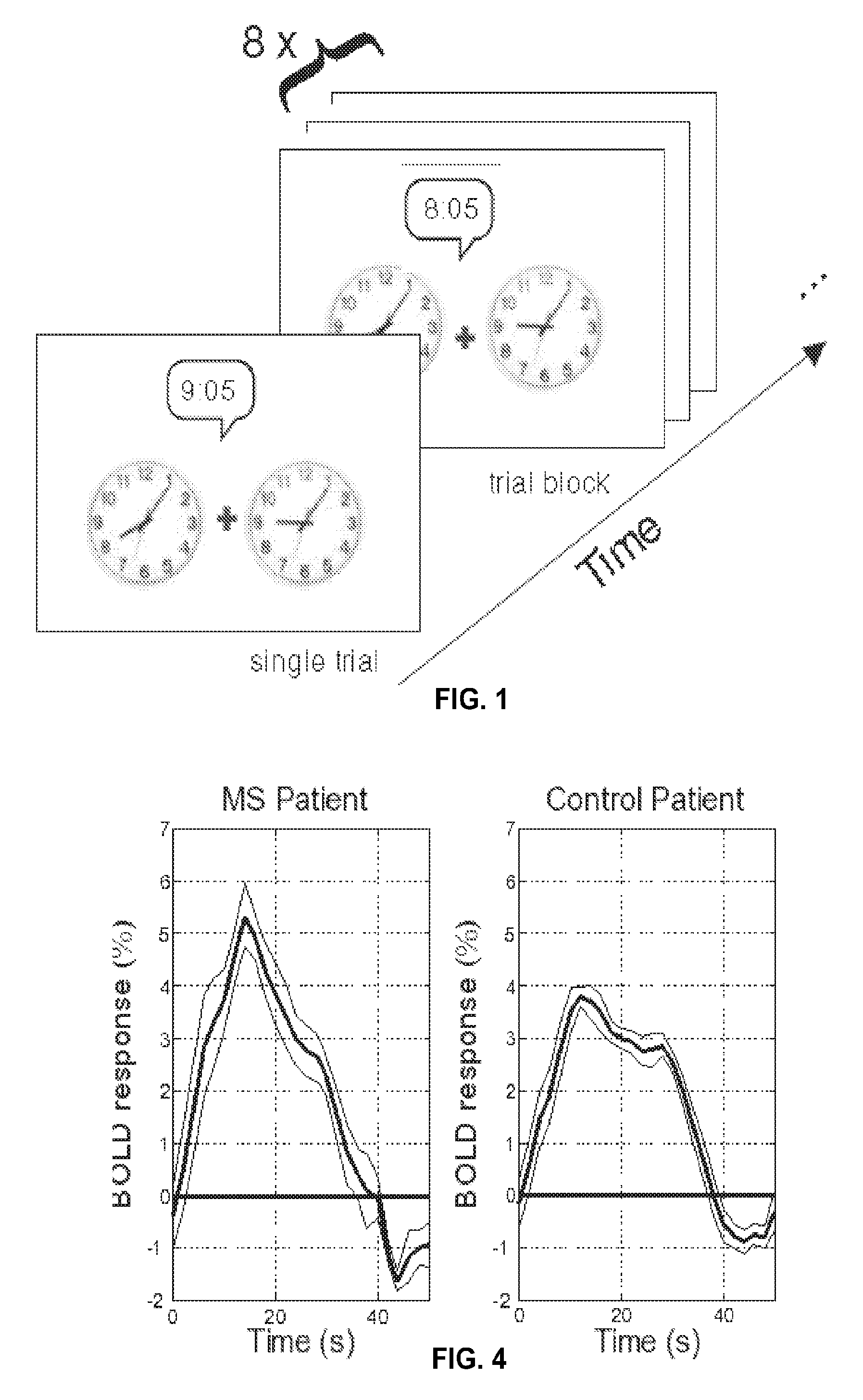

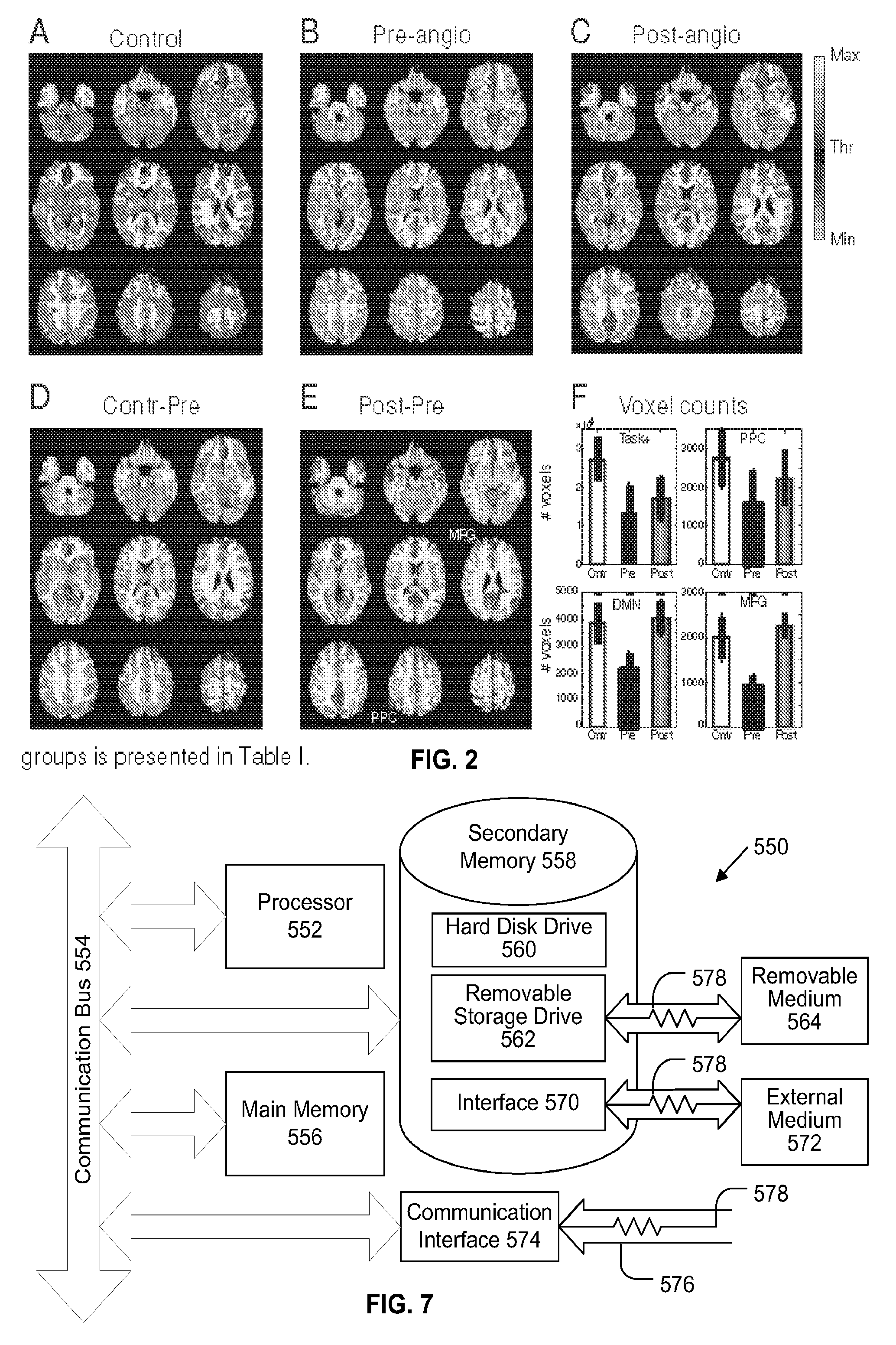

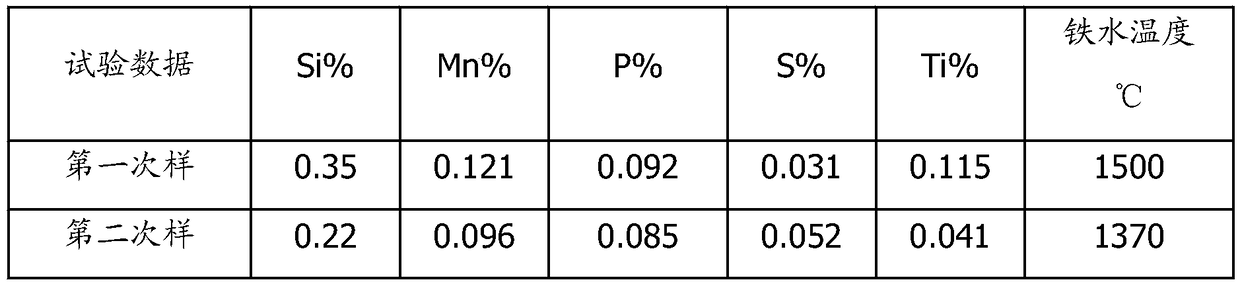

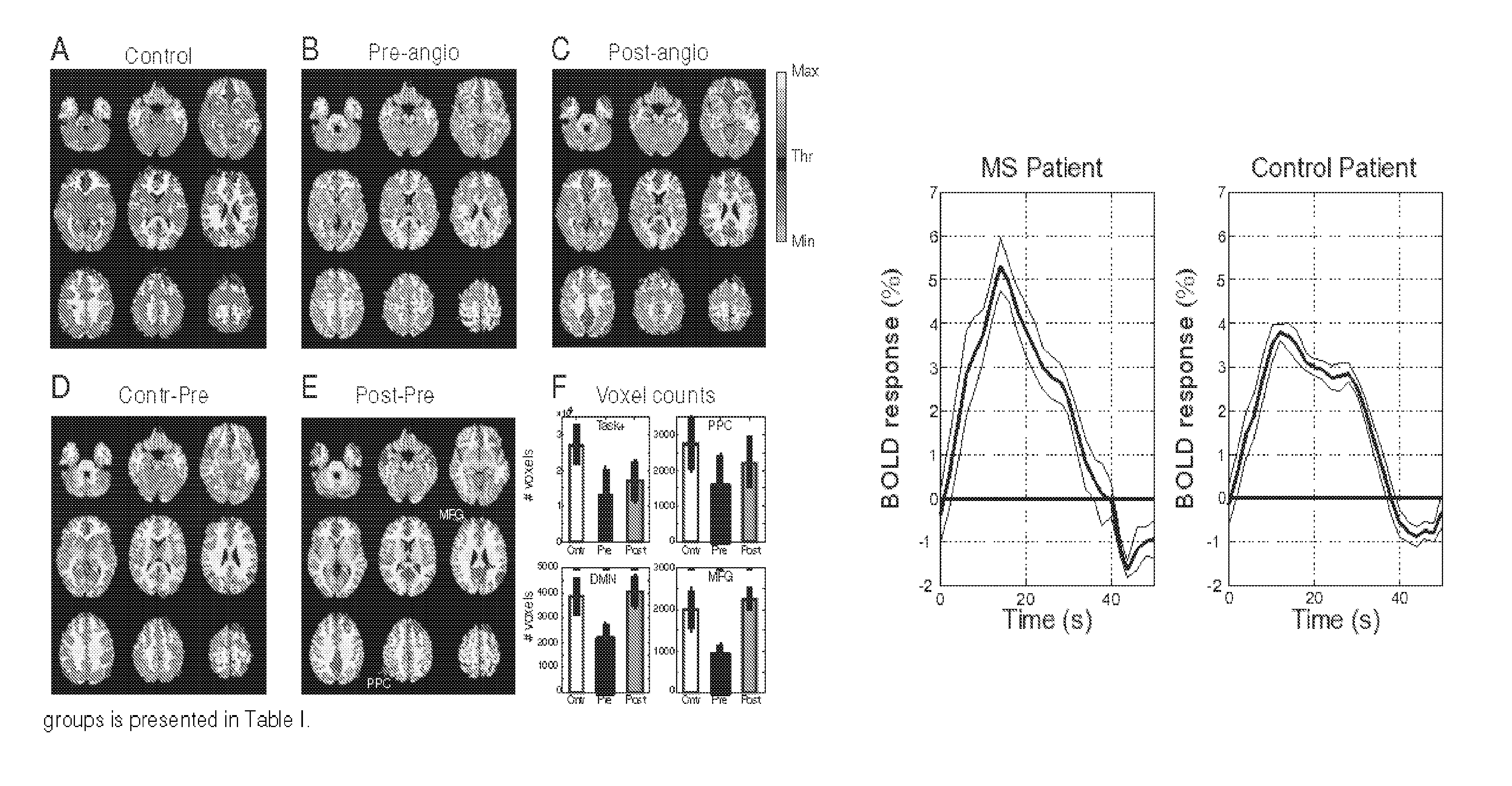

Method to Diagnose and Measure Vascular Drainage Insufficiency in the Central Nervous System

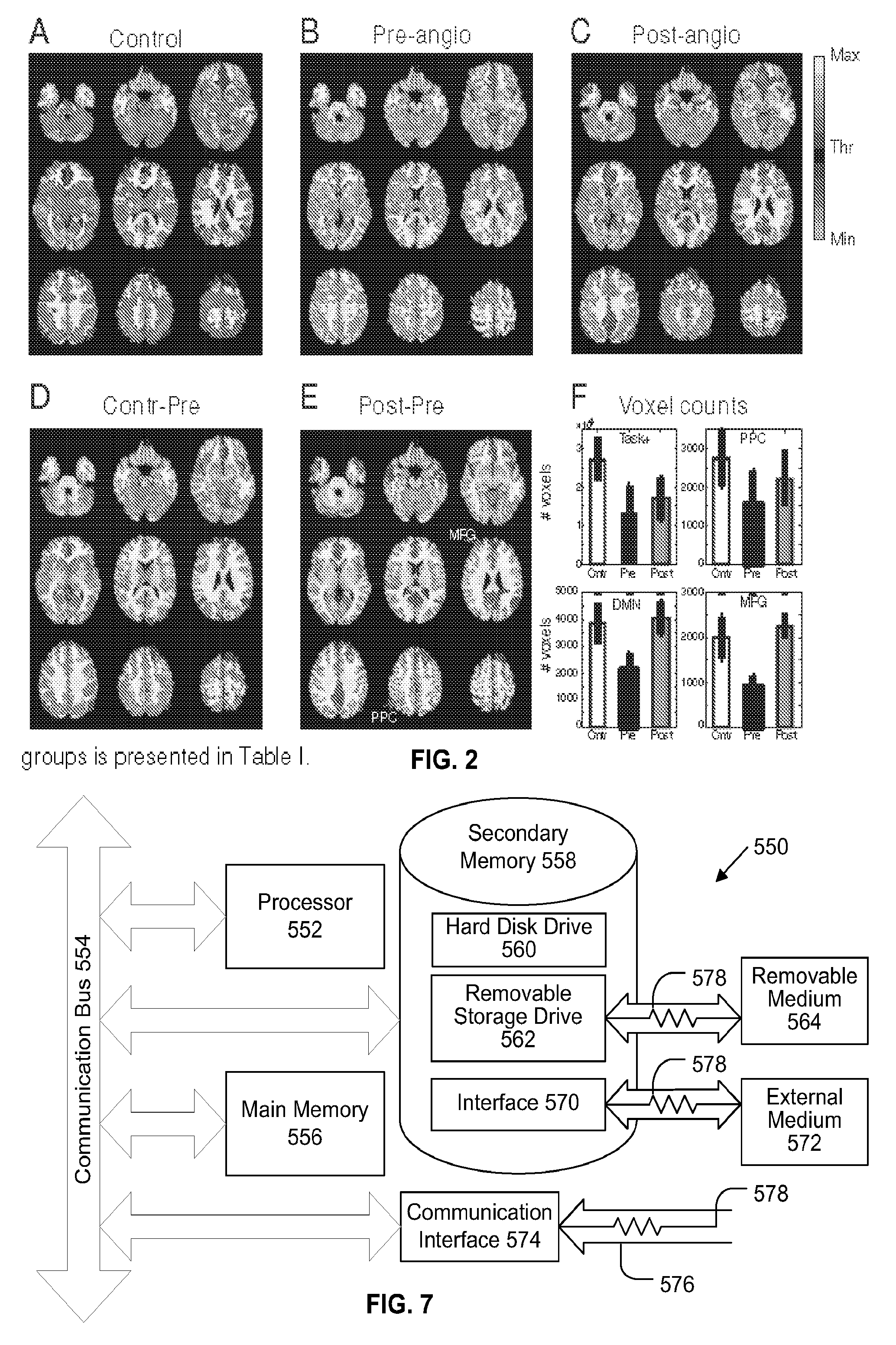

InactiveUS20120277572A1Increased post-stimulus undershootReturn to normal activitiesSensorsBlood flow measurementDiseaseBiological activation

Neurodegenerative diseases, such as multiple sclerosis, may be caused or aggravated by insufficient venous draining from the central nervous system. Functional MRI measures the surge of blood flow into localized regions of cerebral cortex in response to activation of those regions by performing visual, auditory or executive tasks. These fMRI measurements are based on blood-oxygen-level dependence. The resulting fMRI / BOLD data is converted to hemodynamic response data and analyzed to determine any abnormality in the hemodynamic response data. Vascular drainage insufficiency is identified in the presence of abnormal hemodynamic response data. Abnormal hemodynamic response data can be determined by a negative trough in a graph of the HDR data or by the duration, depth, or area of the negative trough.

Owner:HUBBARD DAVID R

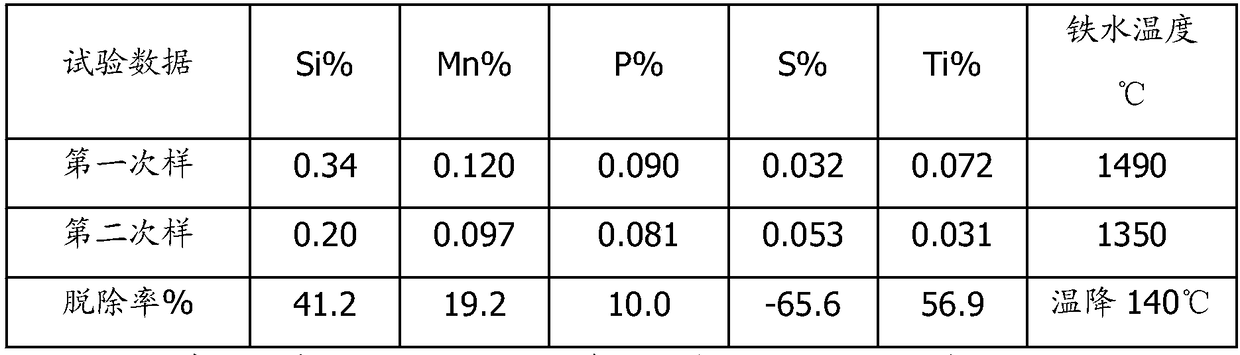

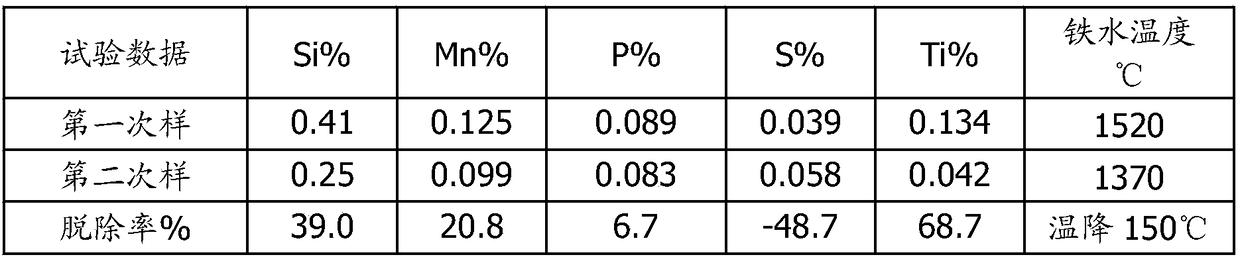

Molten steel dephosphorization agent and molten steel dephosphorization refining method

The invention provides a molten steel dephosphorization agent and a molten steel dephosphorization refining method. The molten steel dephosphorization method comprises the following steps in sequence: ensuring the oxygen activity is greater than or equal to 5000ppm at the final point of molten iron at the blowing end point of a converter, and adding 5-8kg of a dephosphorization agent into each ton of steel in the process that steel is discharged from the converter, wherein the dephosphorization agent comprises the following components in parts by weight: 85-90 parts of lime and 10-15 parts of fluorite, and the total parts is 100; performing LF ladle refining on the molten iron, melting the slag in an electric heating mode, introducing argon for bottom blowing and stirring to the molten iron at the speed of 80-150Nm<3> / hour so as to provide a sufficient power reaction space to the molten iron and the dephosphorization slag, and subsequently slagging off. The molten steel dephosphorization agent has the beneficial effects that dephosphorization treatment can be performed on the molten iron after smelting and dephosphorization in the converter, so that the rephosphorization phenomenon of the molten iron which is smelted in the converter can be effectively avoided, and the dephosphorization effect is good.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD +2

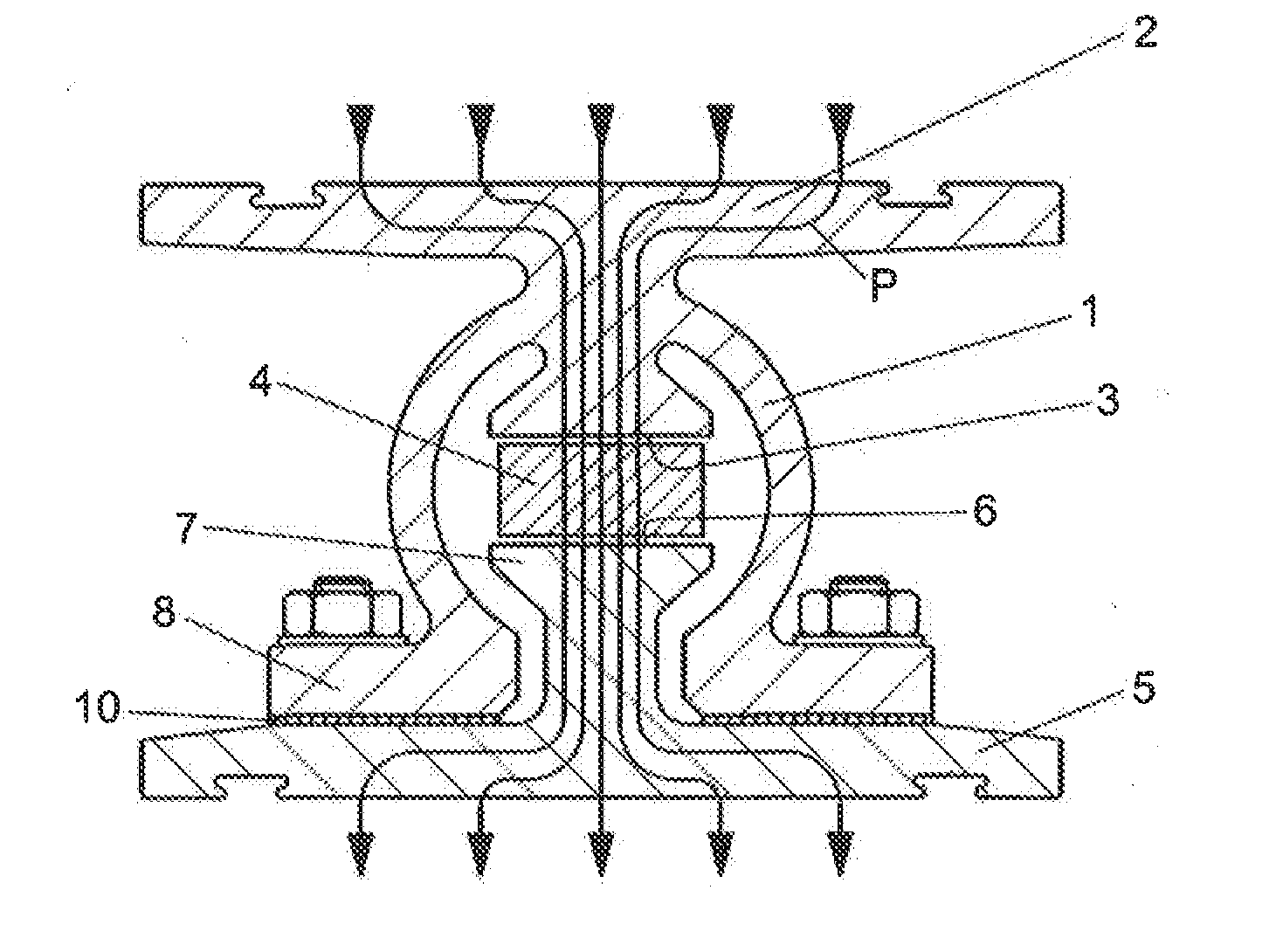

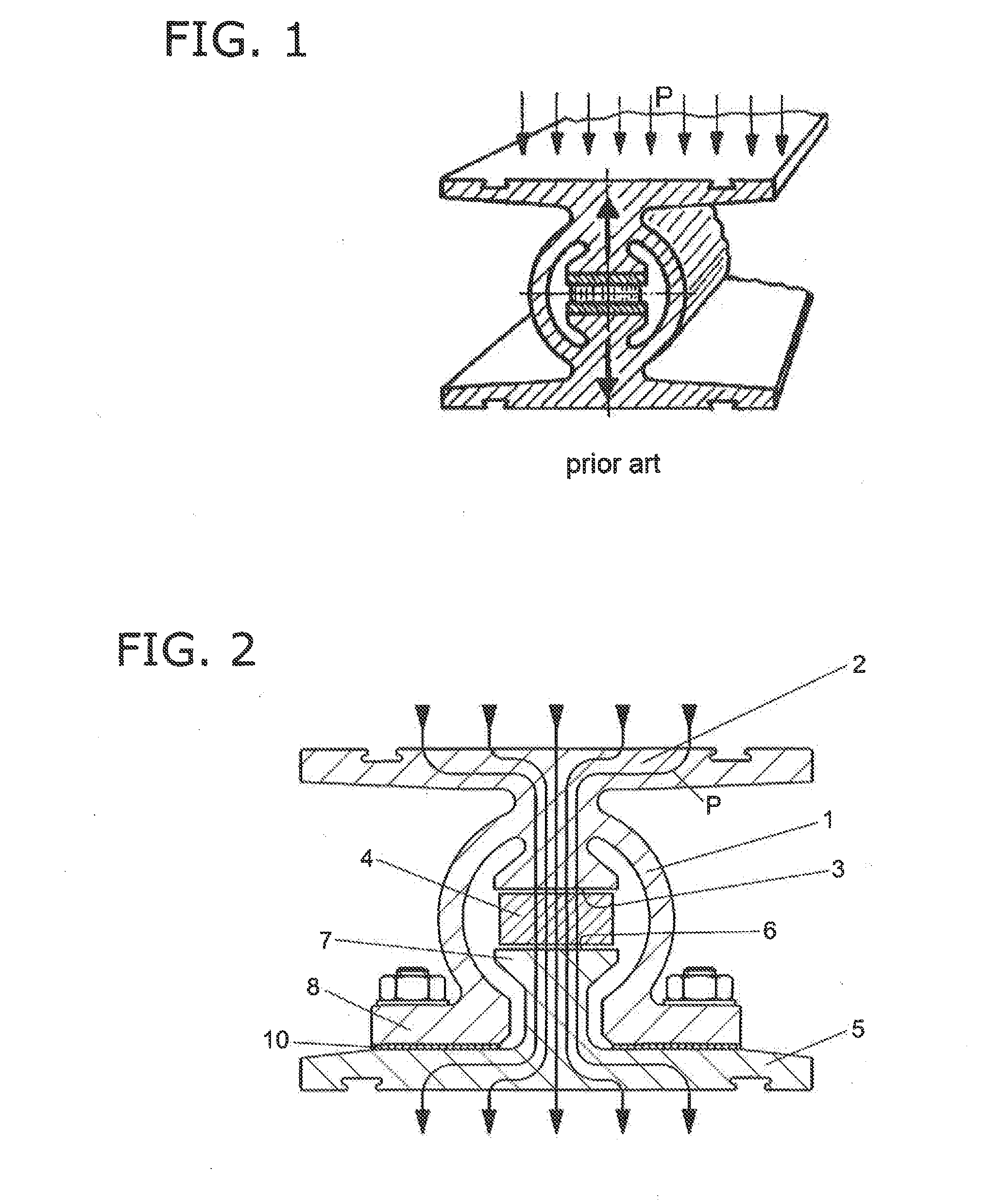

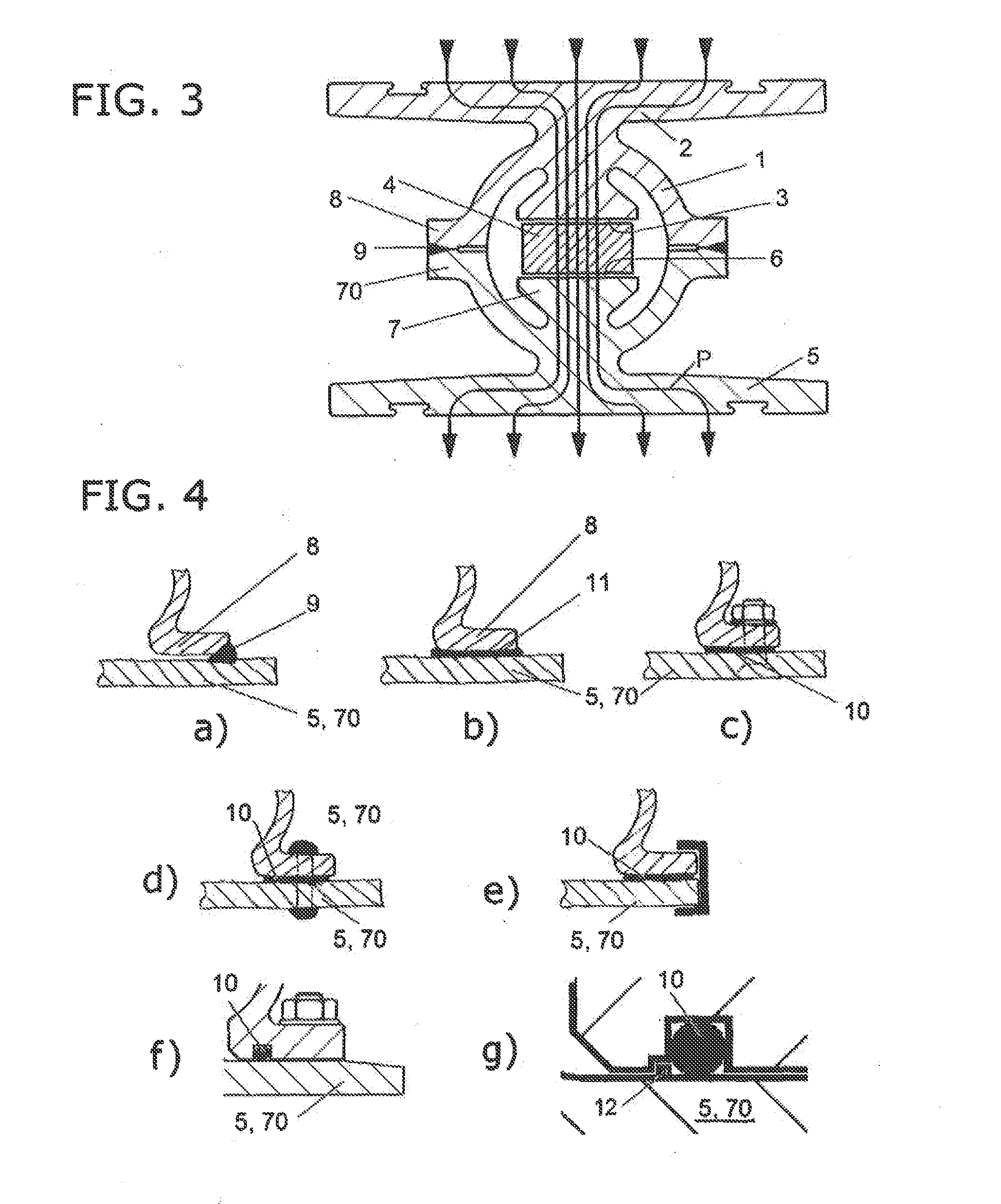

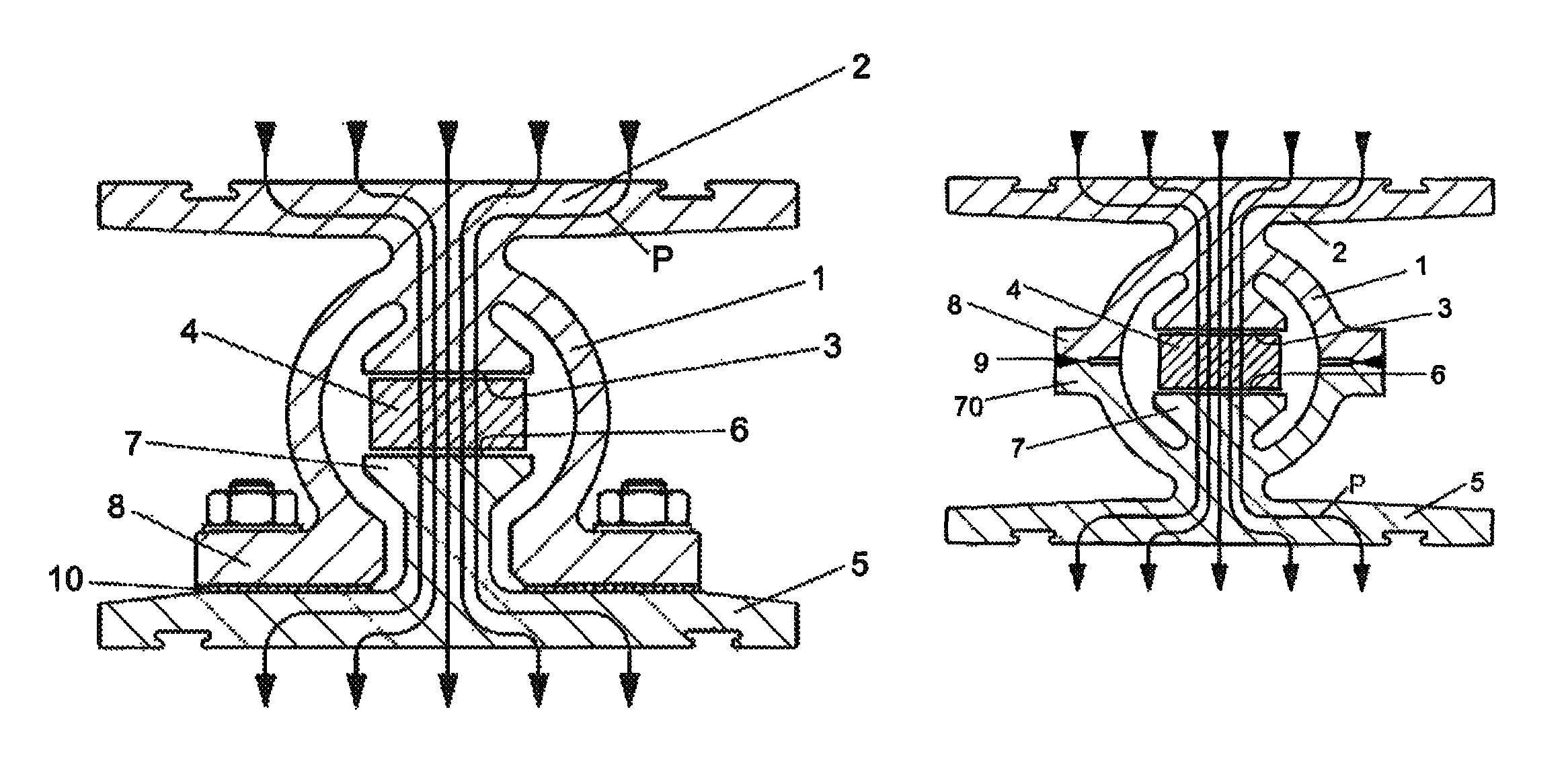

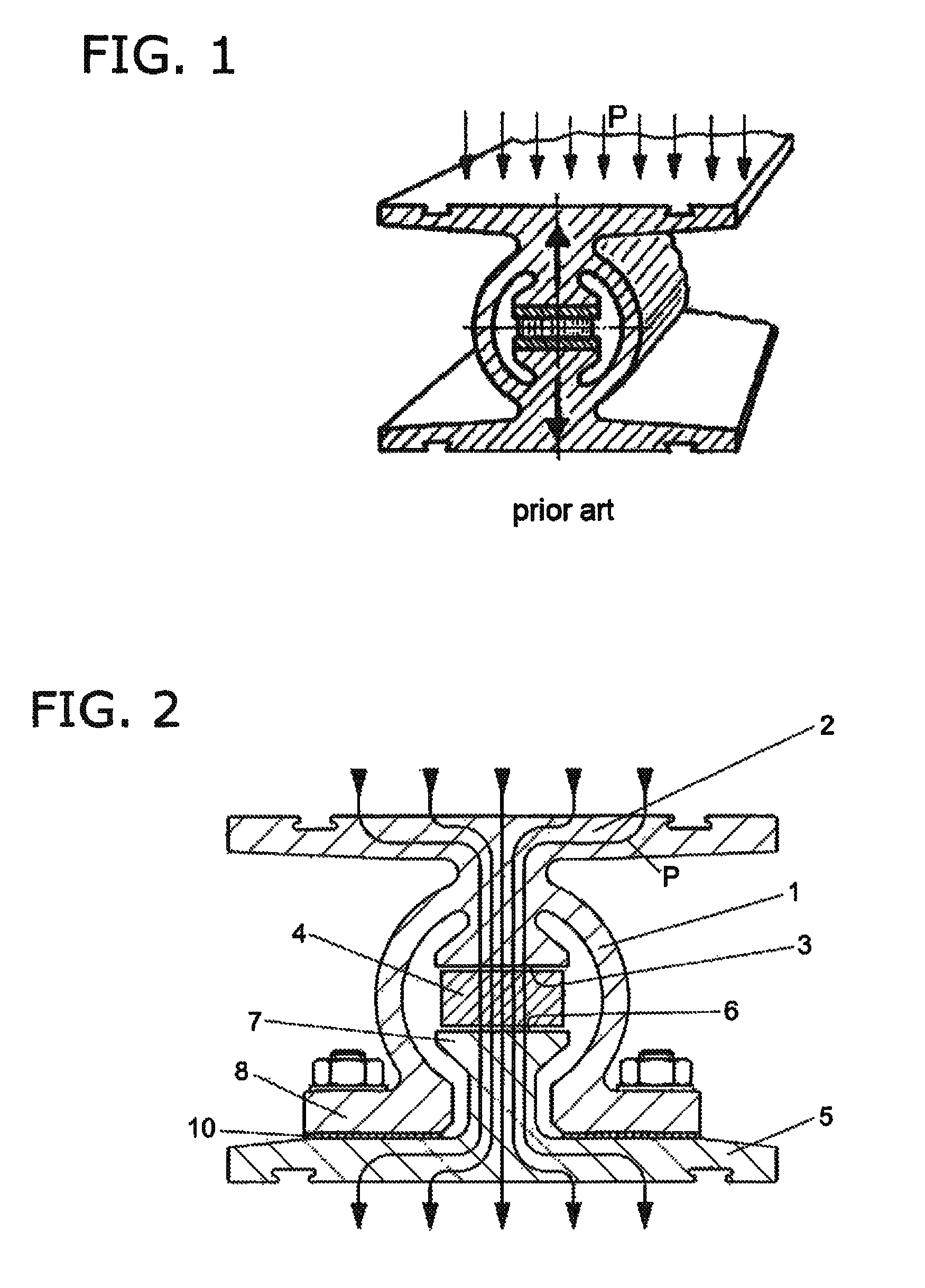

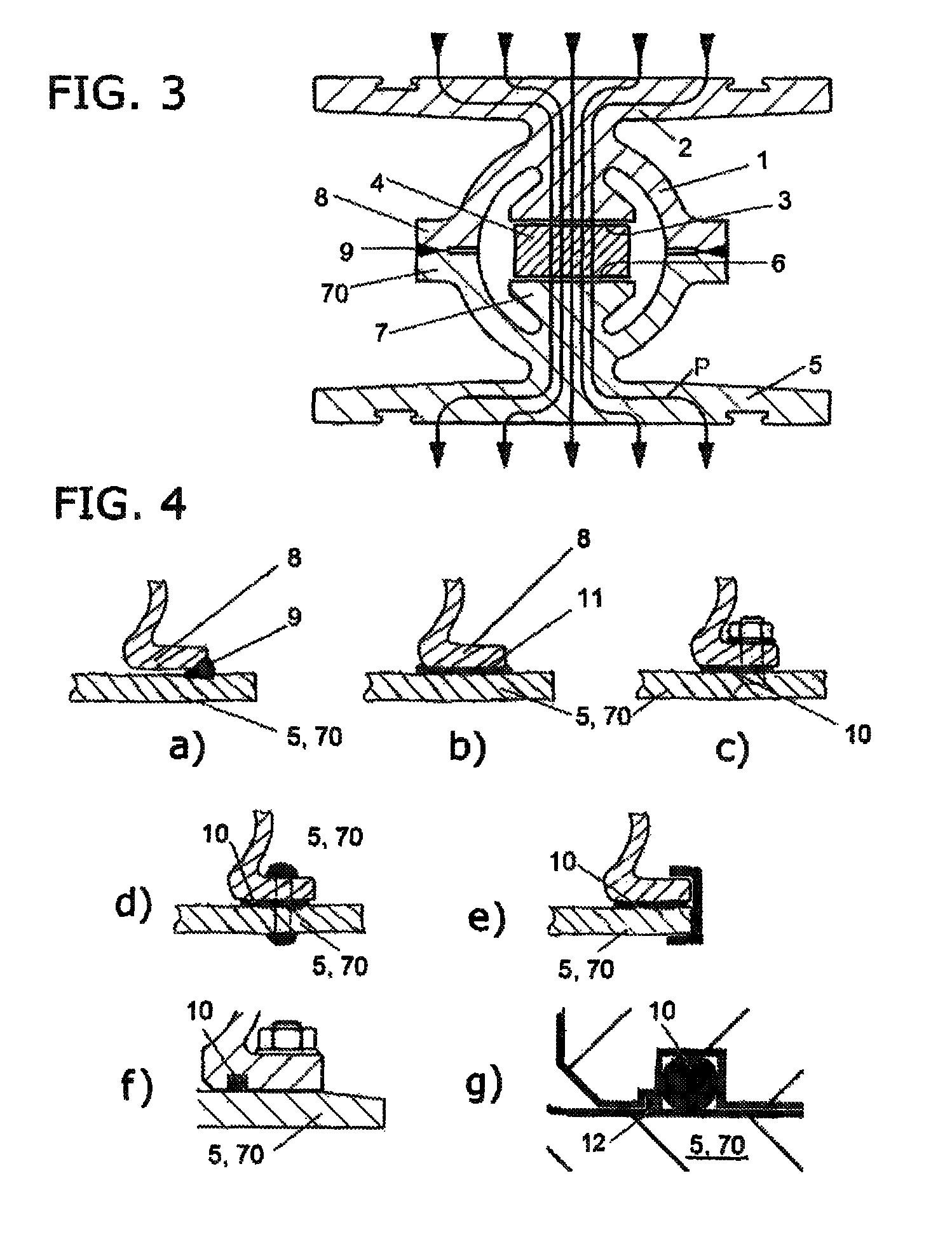

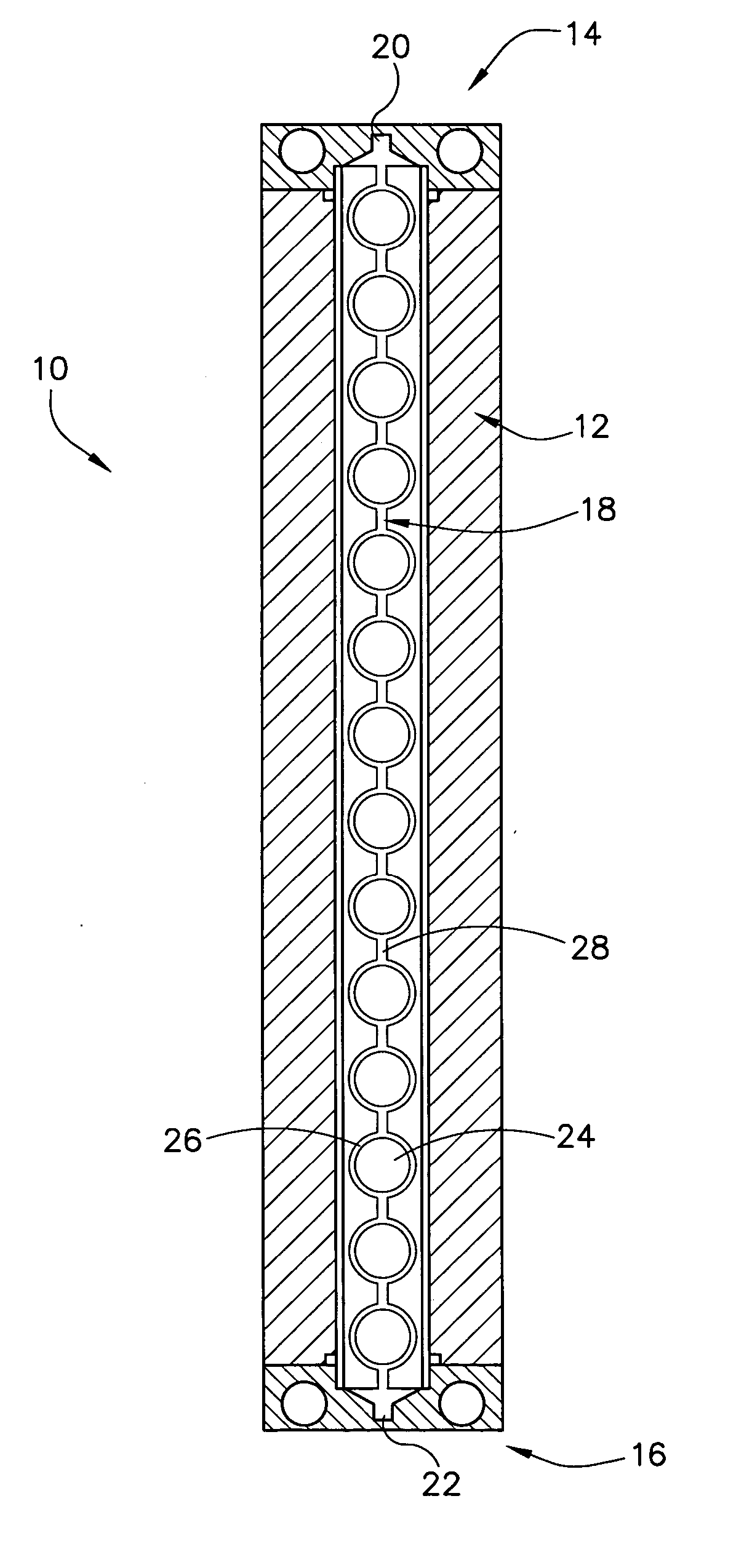

Hollow profile sensor

InactiveUS20140251700A1Weighing apparatus using elastically-deformable membersForce measurement using piezo-electric devicesEngineeringRoad surface

A hollow profile sensor for installation in roads or a road surface for the purpose of sensing the weight of vehicles and / or driving dynamics reactions of vehicles or vehicle wheels to the road includes a tube part having a hollow interior profile. A counterpart is connected to the tube part. A measuring arrangement is held in the hollow interior profile between the tube part and the counterpart. A force introduction flange is connected to the tube part in such a manner that force application lines are concentrated on the measuring arrangement.

Owner:KISTLER HLDG AG

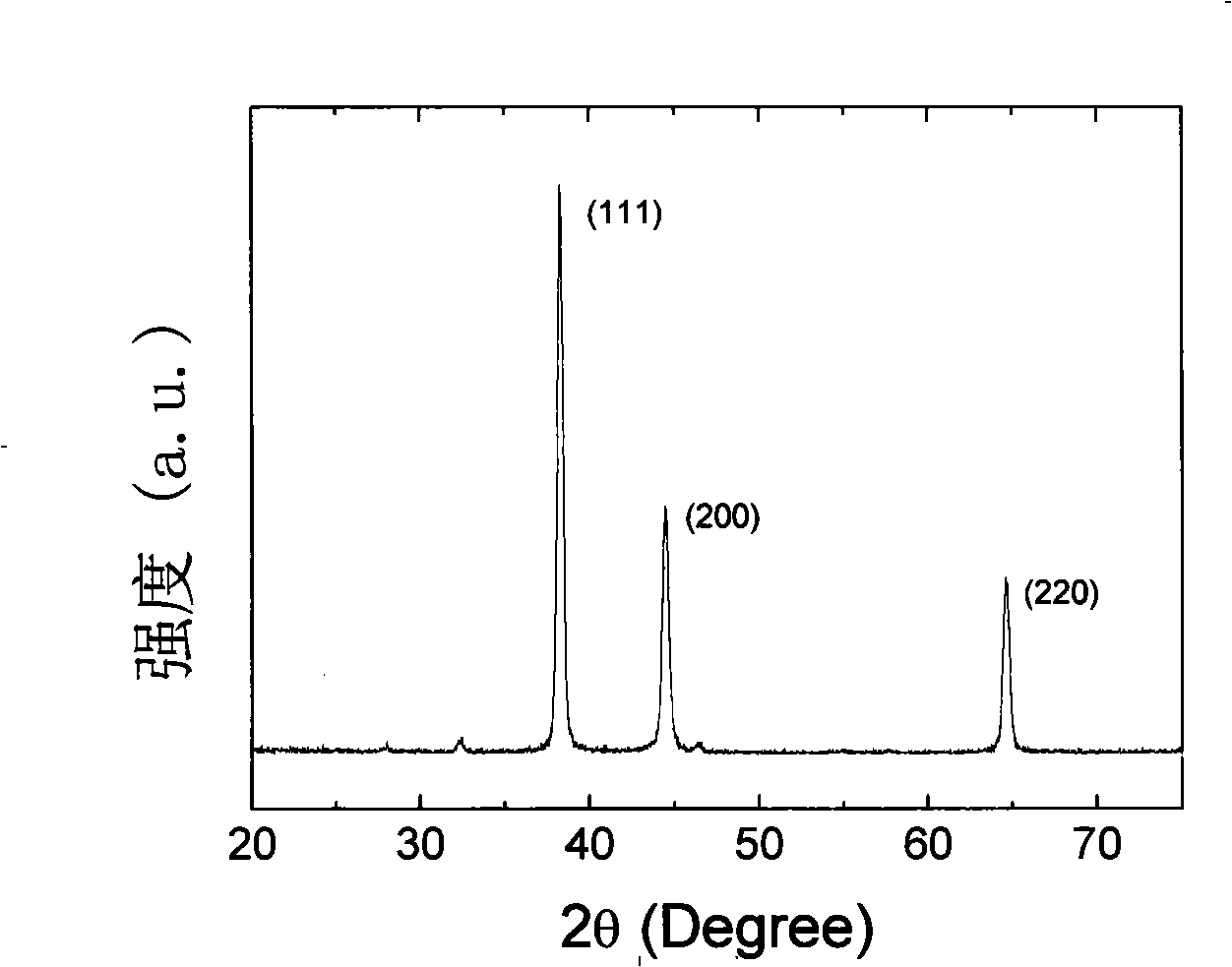

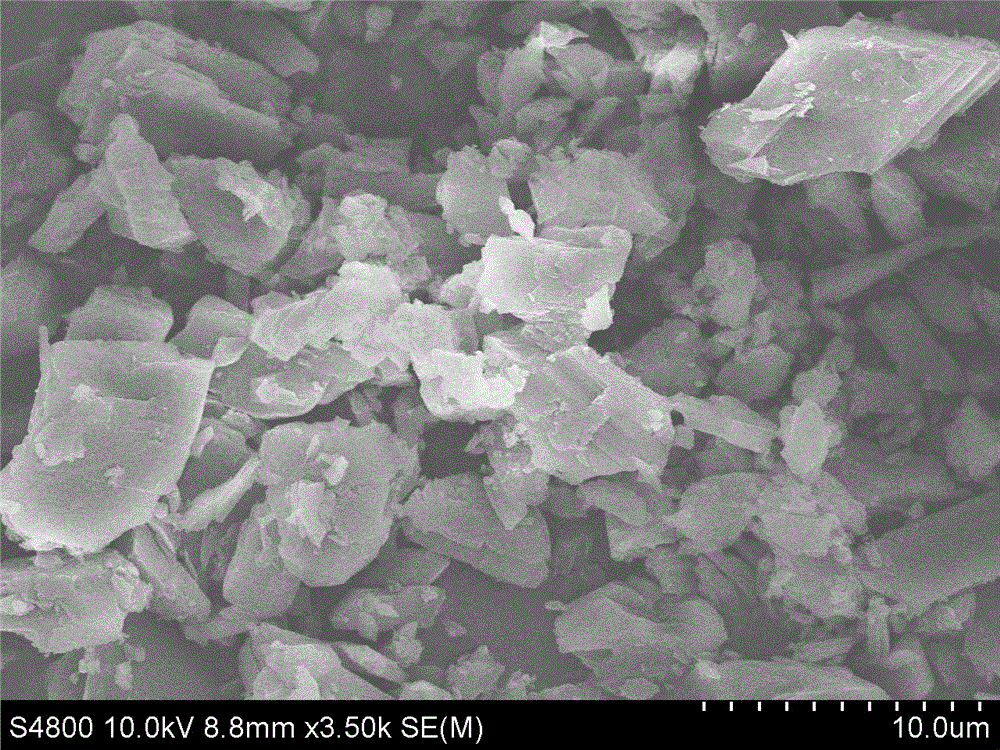

Nanometer metal/carbon composite material as well as preparation method and application thereof

The invention discloses a nanometer metal / carbon composite material as well as a preparation method and application thereof. According to the nanometer composite material, amorphous carbon spheres serve as a skeleton, metal elements are embedded in a carbon layer uniformly, and spherical granules with the granularity of 100 to 500 nm are formed. The amorphous carbon sphere has a loose and porous structure, the specific surface area is between 300 m<2> / g and 1000 m<2> / g, and the grain diameter of the quantum metal elements is between 3 nm and 10 nm. The porous structures in the amorphous carbonspheres provide a large amount of active sites and are favorable for performing oxygen adsorption and precipitation kinetics reaction; meanwhile, the metal elements embedded in the carbon layer can improve the catalytic activity of carbon material oxygen precipitation. The nanometer composite material shows high catalytic activity when serving as a catalyst, has the characteristics of low cost and excellent catalytic property relative to the existing method for preparing the catalyst, and is suitable for large-scale marketization application.

Owner:CENT SOUTH UNIV

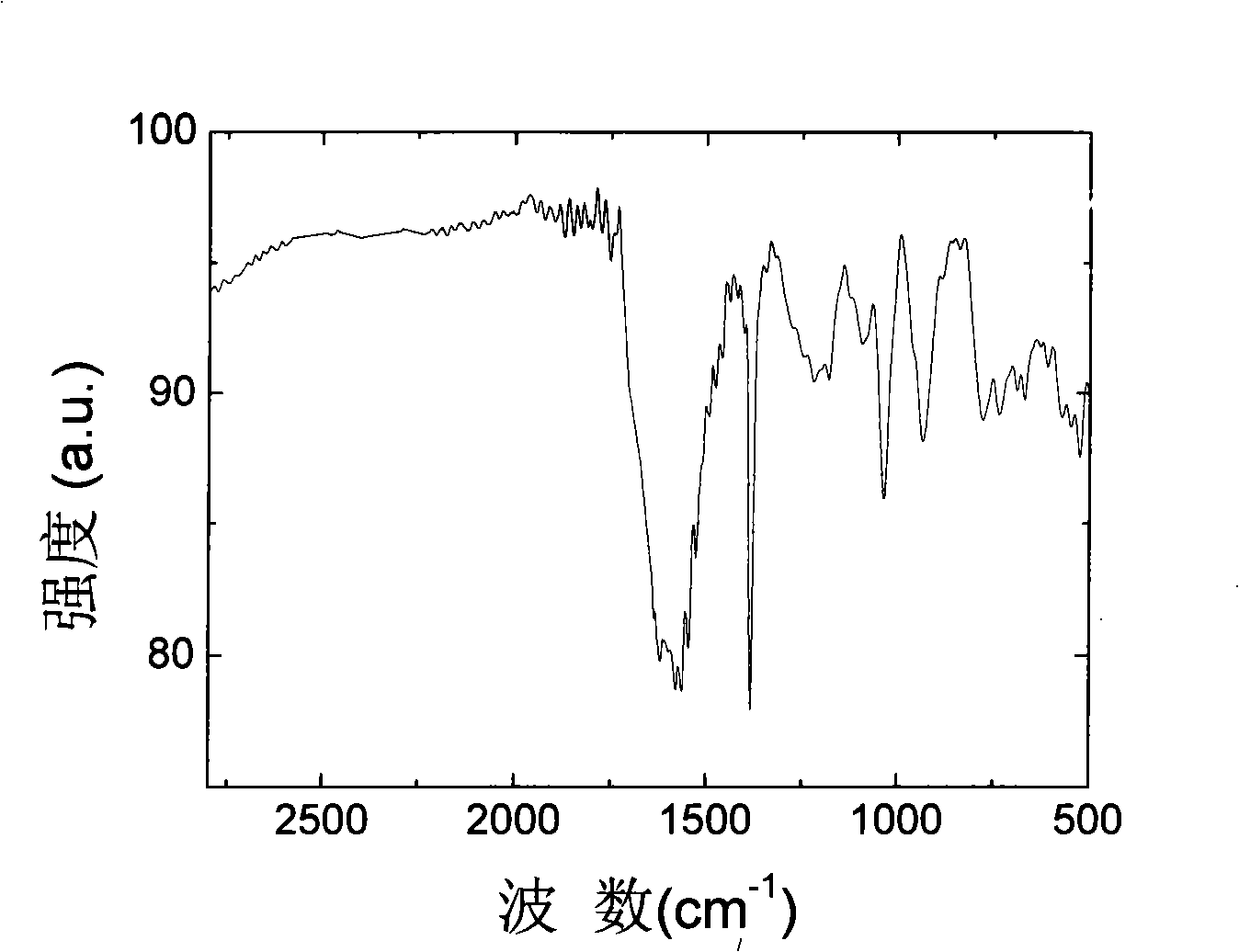

Method for rapidly preparing Ag/PPy composite material

The invention discloses a method for quickly preparing a silver / polypyrrole composite material. Utilization of the redox reaction between silver salt and pyrrole monomer is a simple and effective method for preparing the silver / polypyrrole composite material, but the defect of low speed of the dynamic reaction is existed in the reaction; the invention provides a method in which hartshorn is added in the reaction system, which effectively speeds up the reaction speed: a stable Ag / Ppy composite film can be formed within 0.5h, and the blue Ag / Ppy composite sol can be formed within 4h.

Owner:EAST CHINA UNIV OF SCI & TECH

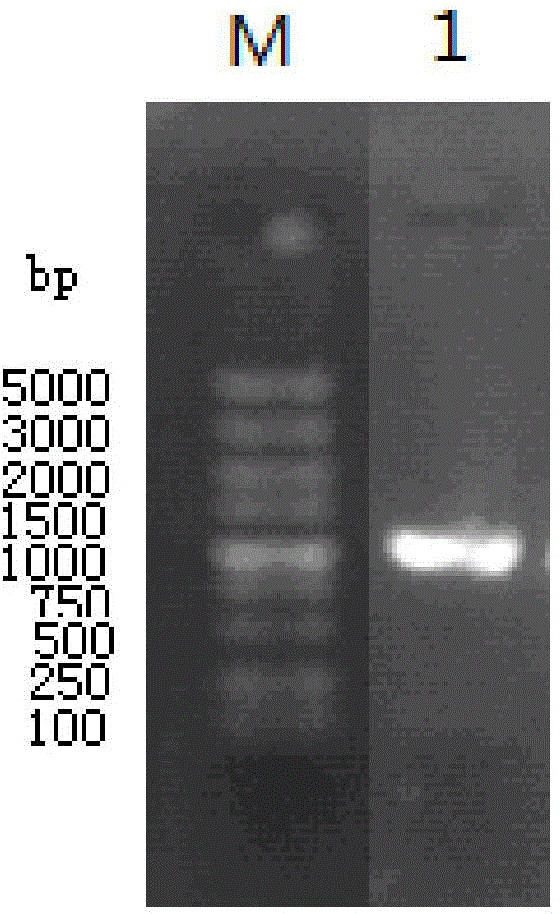

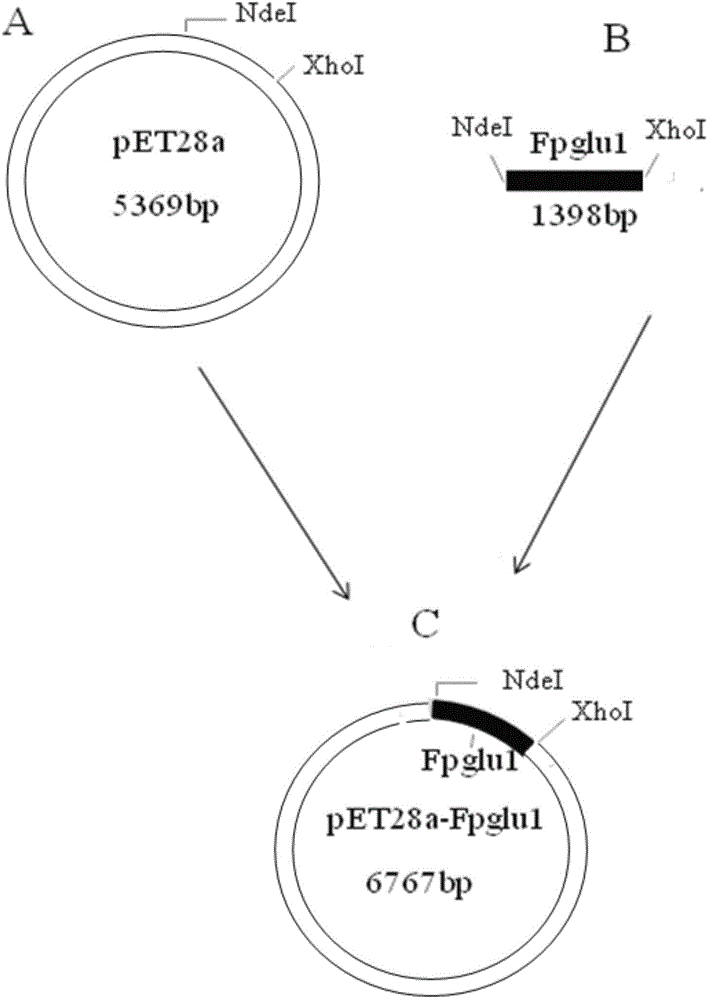

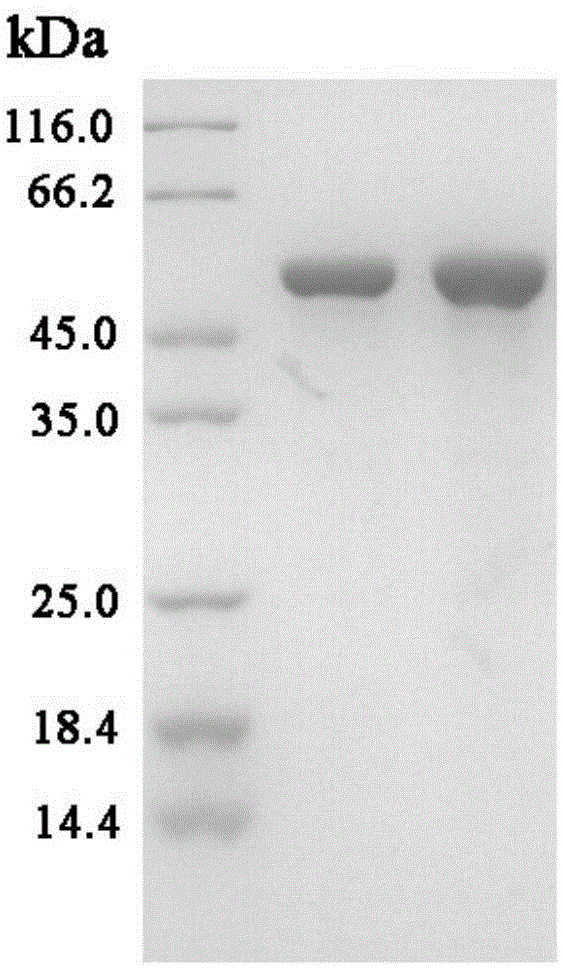

Hyperthermophilic glycosidase mutant and application thereof in preparation of ginsenoside CK

The invention relates to a hyperthermophilic glycosidase mutant and an application thereof in preparation of ginsenoside CK, and belongs to the technical field of biotechnology engineering. An amino acid sequence of the hyperthermophilic glycosidase mutant is as shown in SEQ ID NO:2; and the hyperthermophilic glycosidase mutant is applied to preparation of rare ginsenoside CK. The hyperthermophilic glycosidase mutant has high heat resistance and stability; relatively high catalytic activity can still be kept after heat preservation at 70-80 DEG C for over 300 hours, and thus hyperthermophilic glycosidase mutant has the advantages of low storage and transportation cost, and low requirement standards on a cooling system of a reactor when applied to production; the kinetic reaction is accelerated; meanwhile, the hyperthermophilic glycosidase mutant has beta-glucosaccharase activity; glucosides of main protopanaxadiol type saponins C3 site and C20 site can be hydrolyzed on the basis that the saponin structure is not destroyed; and the hyperthermophilic glycosidase mutant is efficient, specific, few in byproducts, high in yield and the like, so that the Fpglula can be applied to industrial production of a rare ginsenoside Compound K.

Owner:CHANGCHUN UNIV OF CHINESE MEDICINE

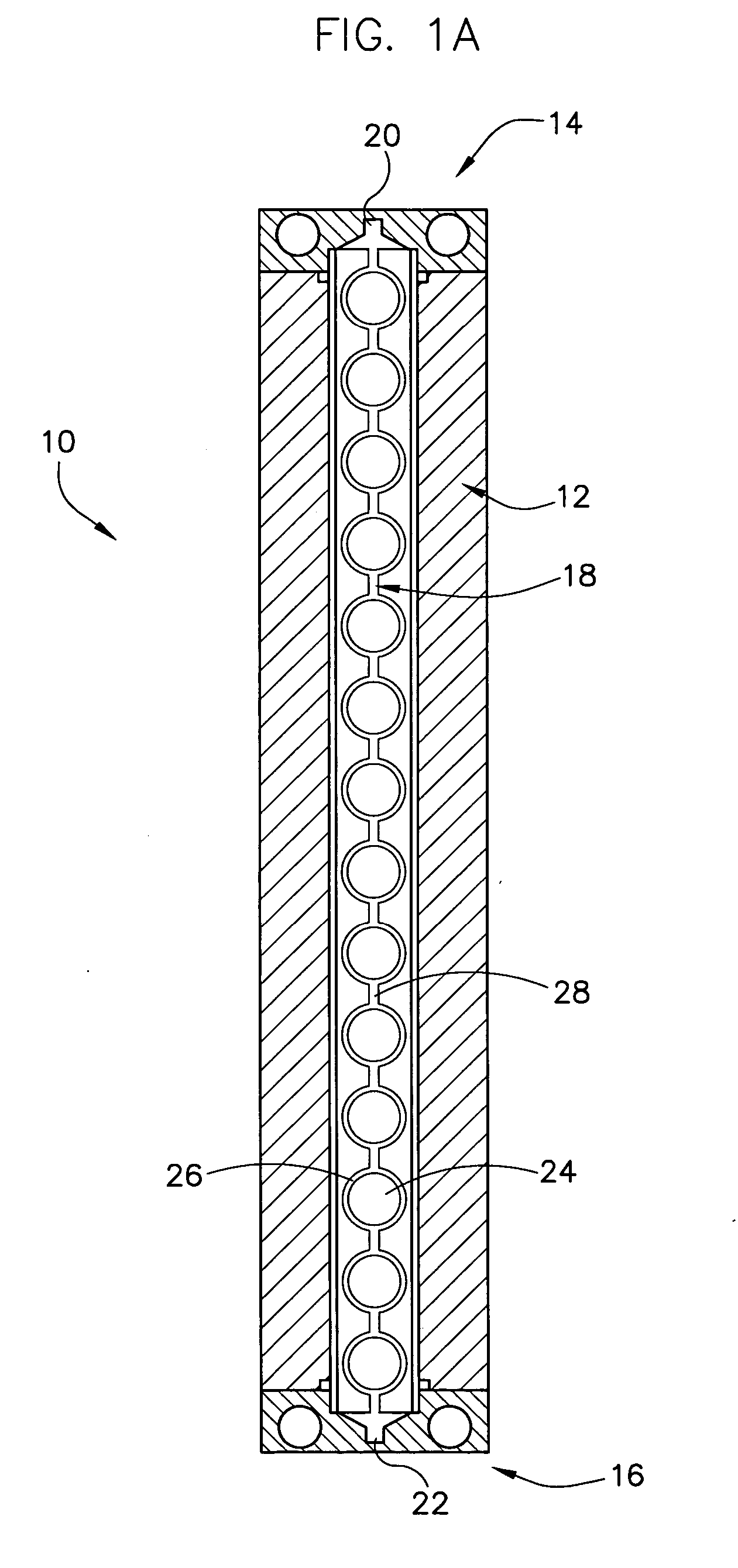

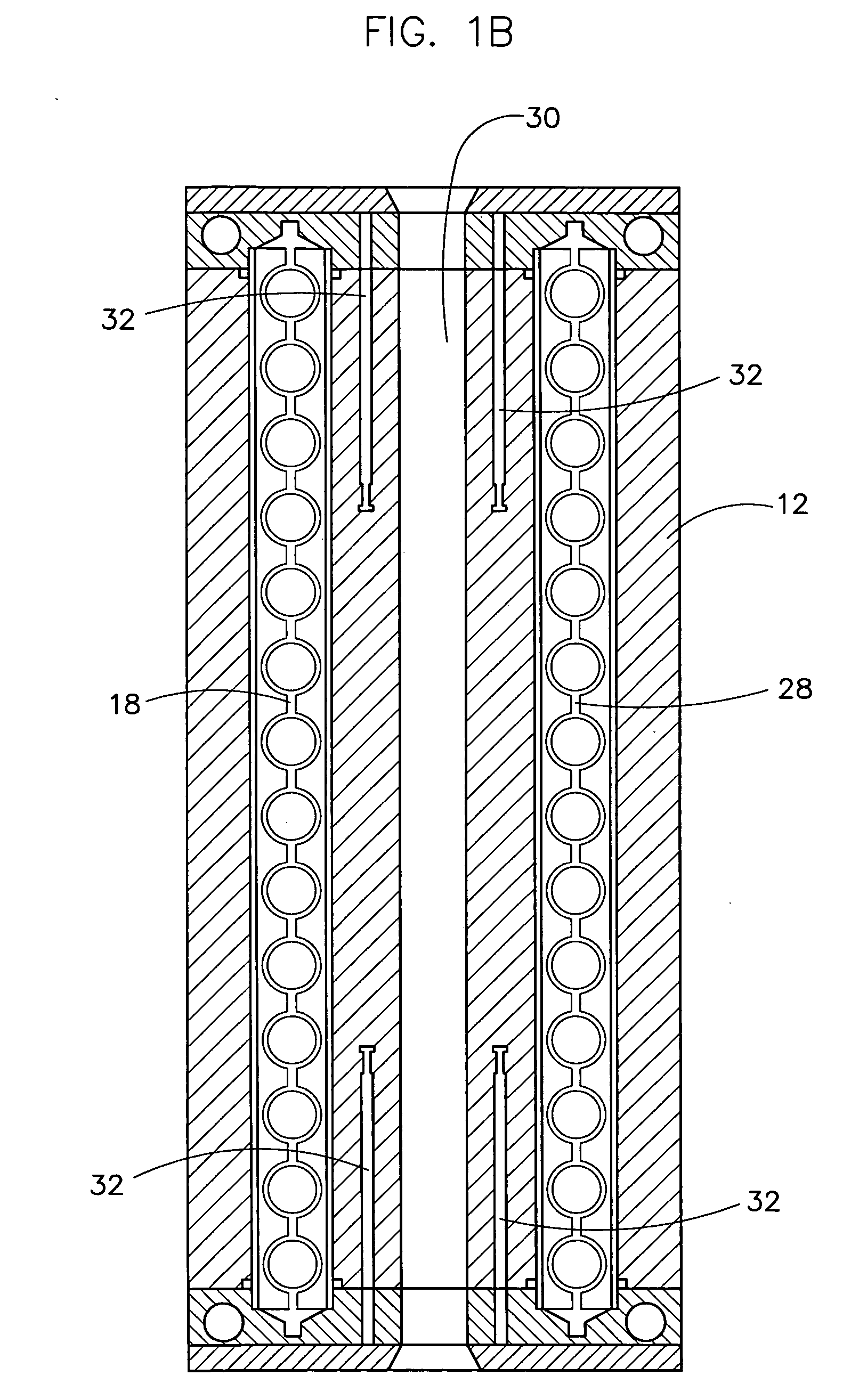

Two part hollow profile sensor

InactiveUS9347816B2Weighing apparatus using elastically-deformable membersForce measurement using piezo-electric devicesRoad surfaceFlange

A hollow profile sensor for installation in roads or a road surface for the purpose of sensing the weight of vehicles and / or driving dynamics reactions of vehicles or vehicle wheels to the road includes a tube part having a hollow interior profile. A counterpart is connected to the tube part. A measuring arrangement is held in the hollow interior profile between the tube part and the counterpart. A force introduction flange is connected to the tube part in such a manner that force application lines are concentrated on the measuring arrangement.

Owner:KISTLER HLDG AG

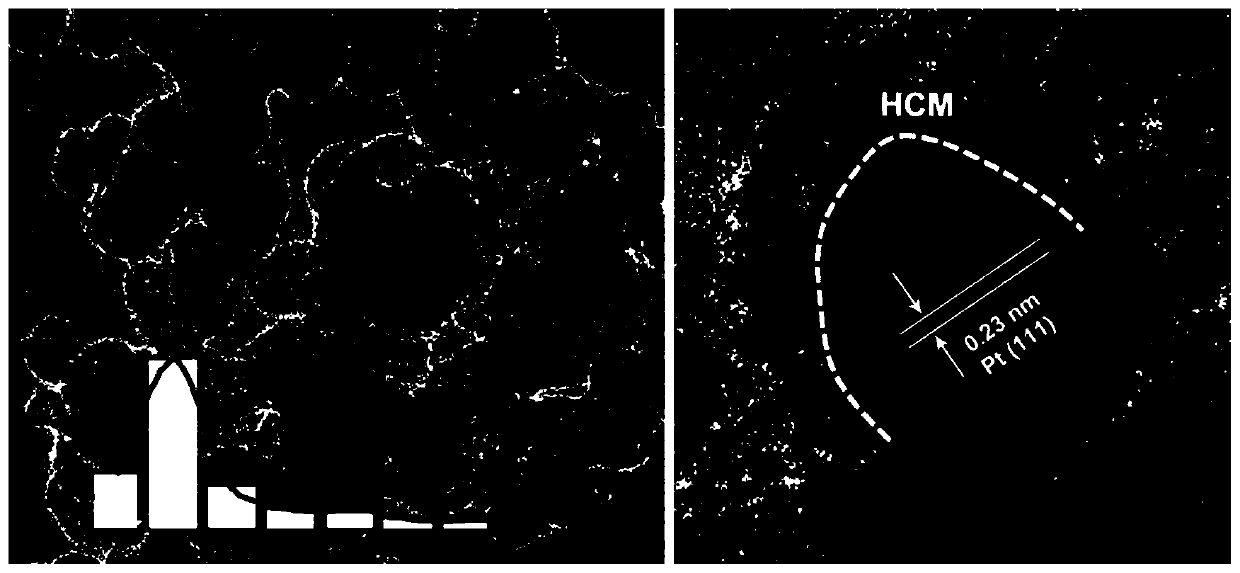

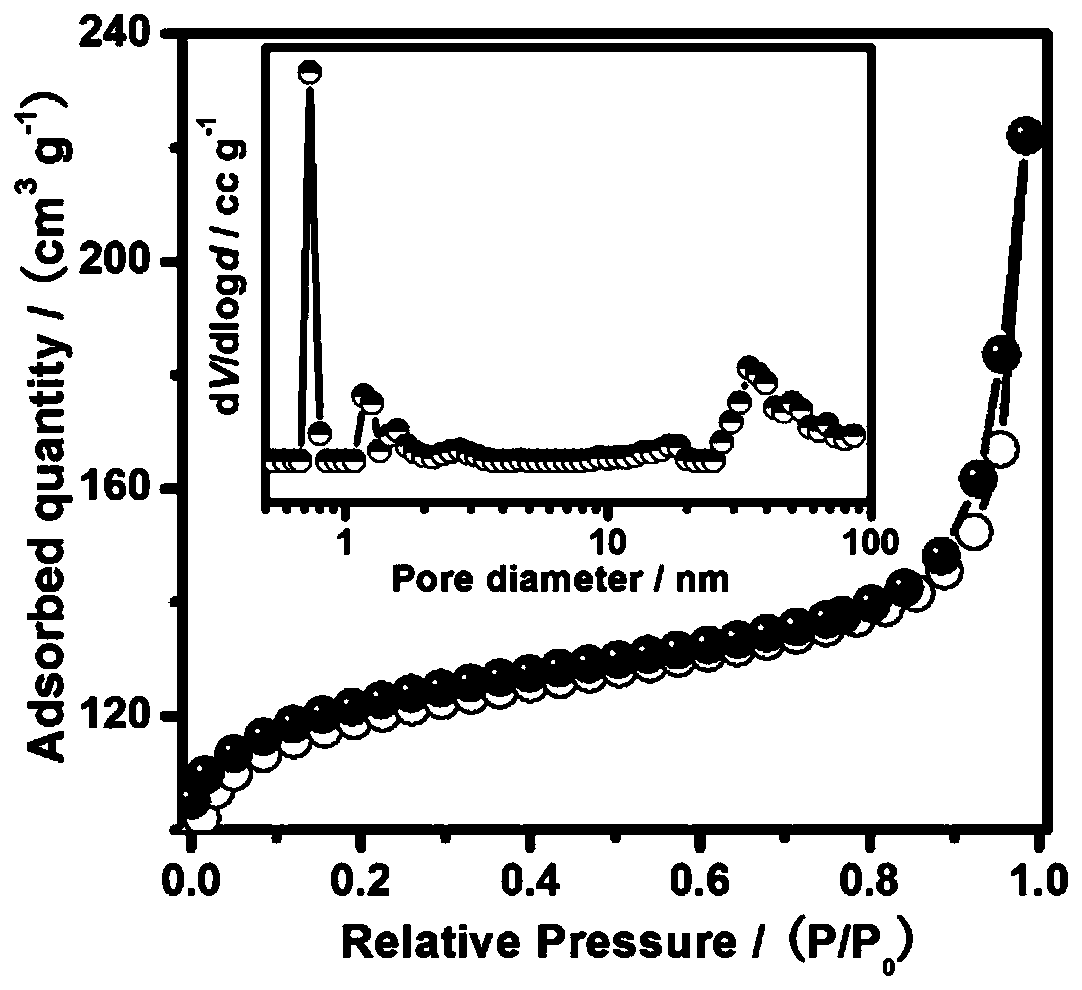

High-performance oxygen reduction catalyst based on surface function enhancement and preparation method thereof

PendingCN109950566AUniform particle sizeEvenly distributedMaterial nanotechnologyFuel and primary cellsReaction rateDesorption

The invention discloses a high-performance oxygen reduction catalyst based on surface function enhancement provides a preparation method of the above catalyst. The catalyst is a HCM / Pt / C catalyst witha core-shell structure, the material of the shell is a porous heteroatom-doped carbon material coating the surface of a Pt active center. Since the heteroatom-doped carbon material has a special adsorption-enrichment effect on oxygen, the material can provide an oxygen-rich environment for an active site, the collision frequency of reaction gas oxygen and the active site is increased, and the kinetic reaction rate of an oxygen reduction reaction is greatly improved. At the same time, the electronic effect at a HCM / Pt interface optimizes the electronic structure of Pt, so that the adsorption of Pt on an oxygen reduction reaction intermediate is weakened, and the desorption rate is increased to provide a site for subsequent oxygen adsorption. On the other hand, a carbon shell around Pt particles prevents migration and agglomeration, and the overall stability of the catalyst is greatly improved.

Owner:江苏介观催化材料科技有限公司

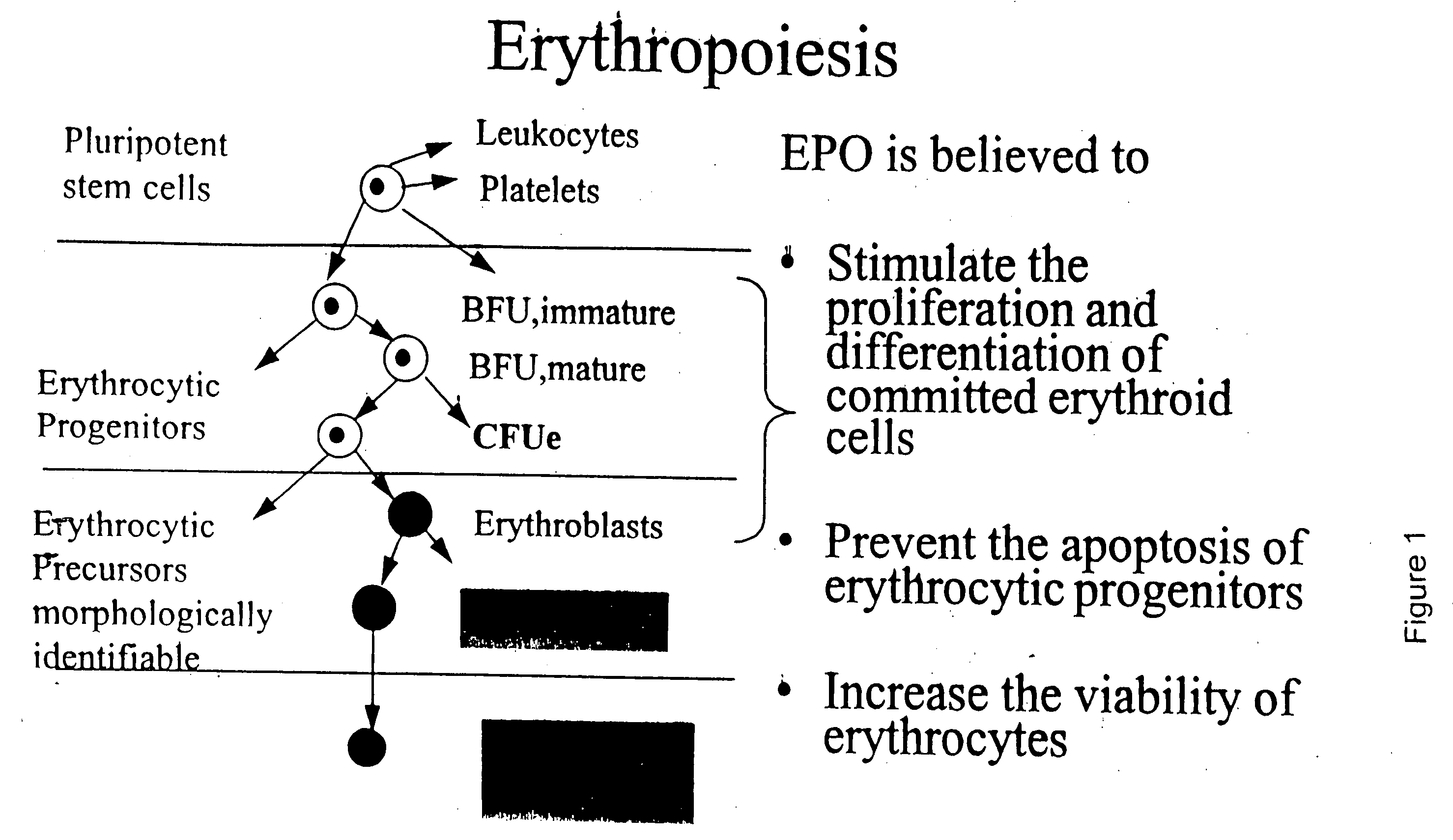

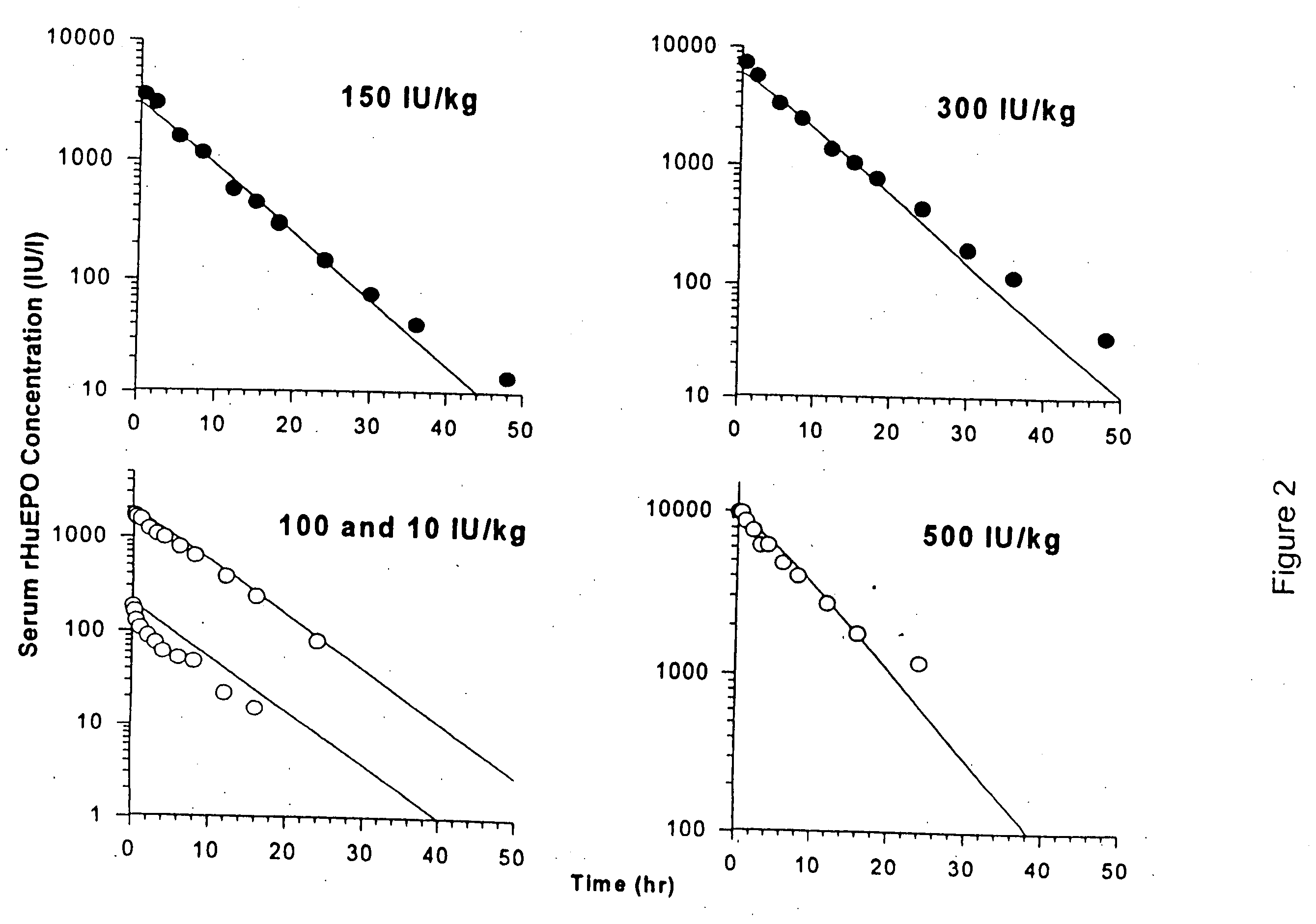

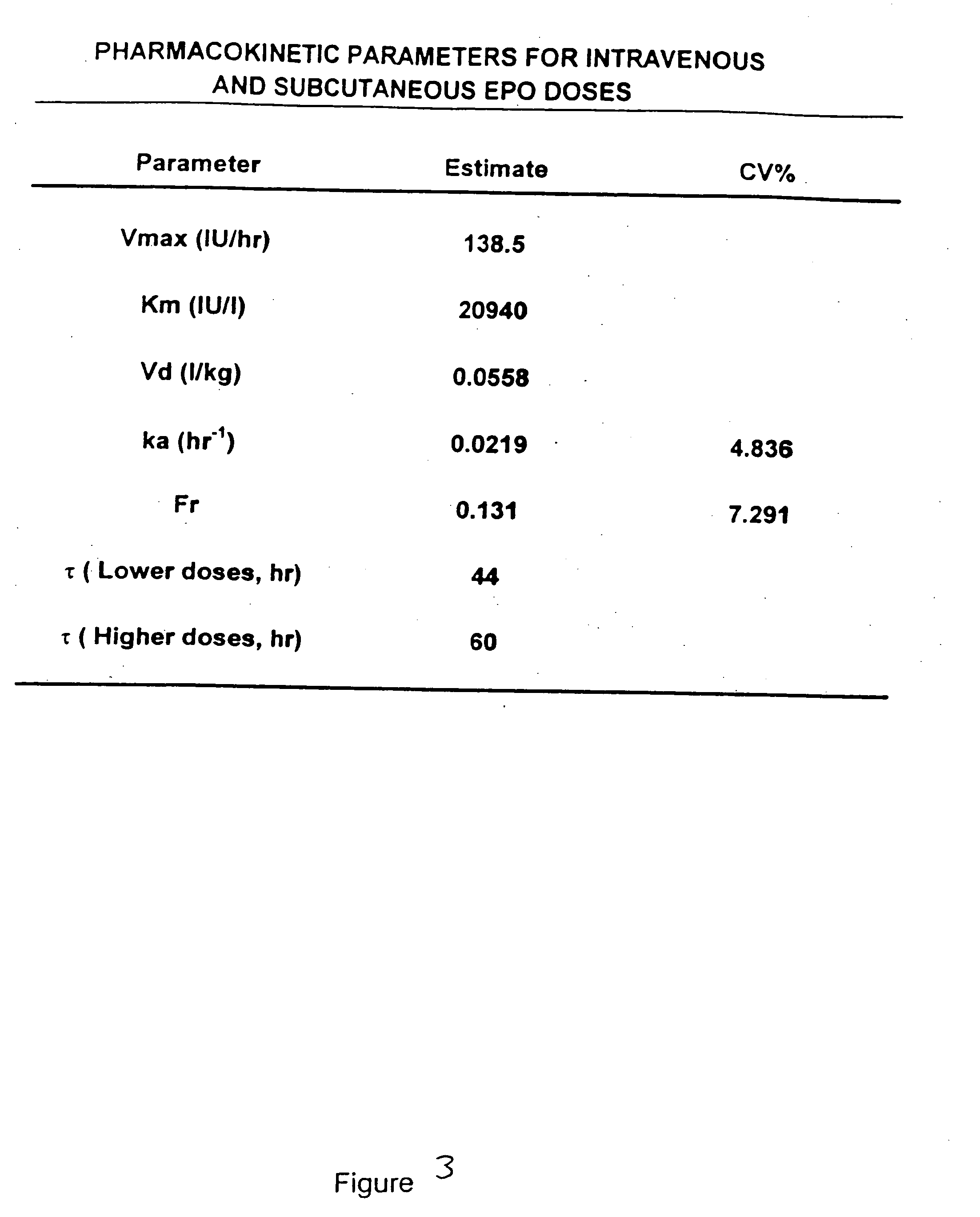

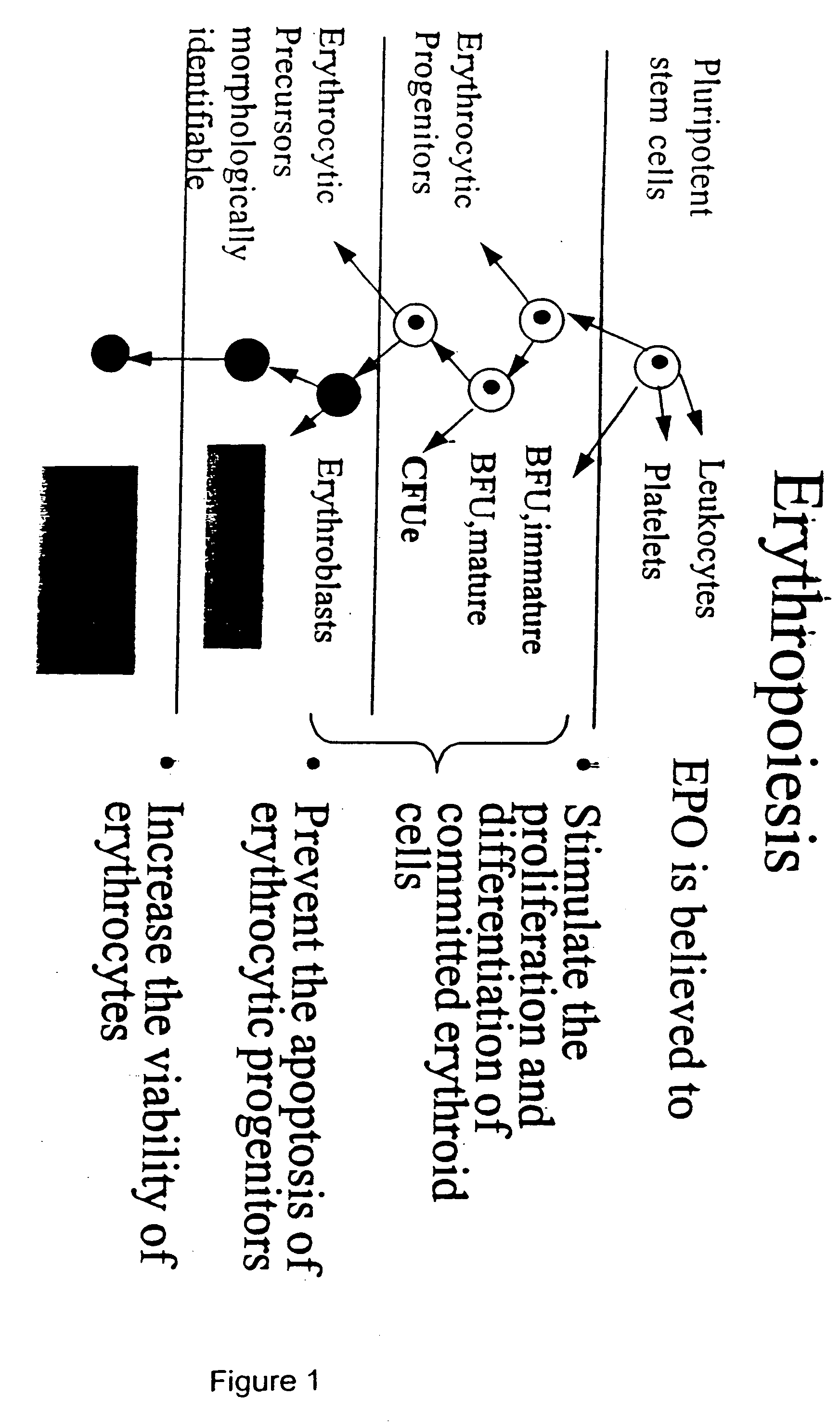

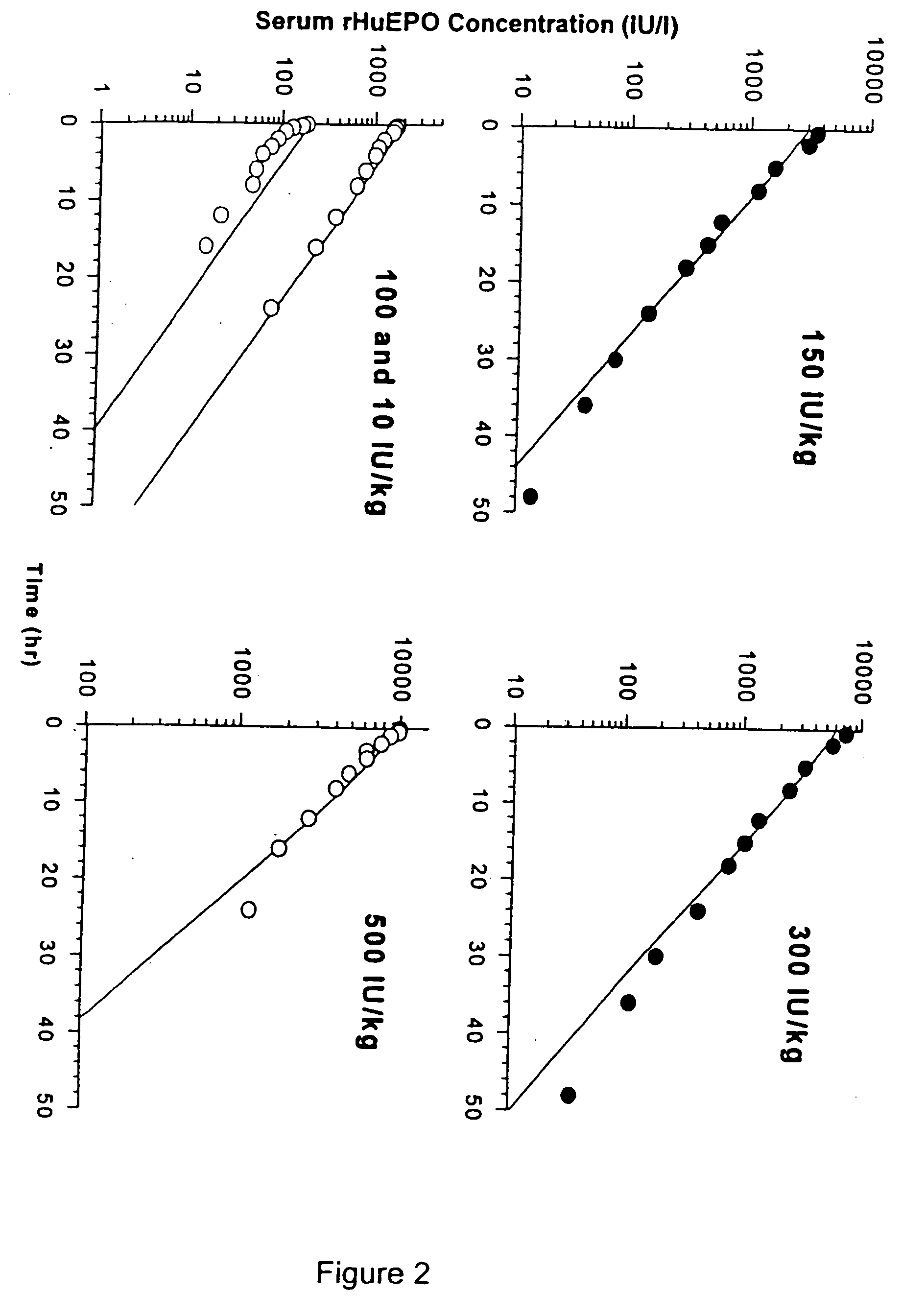

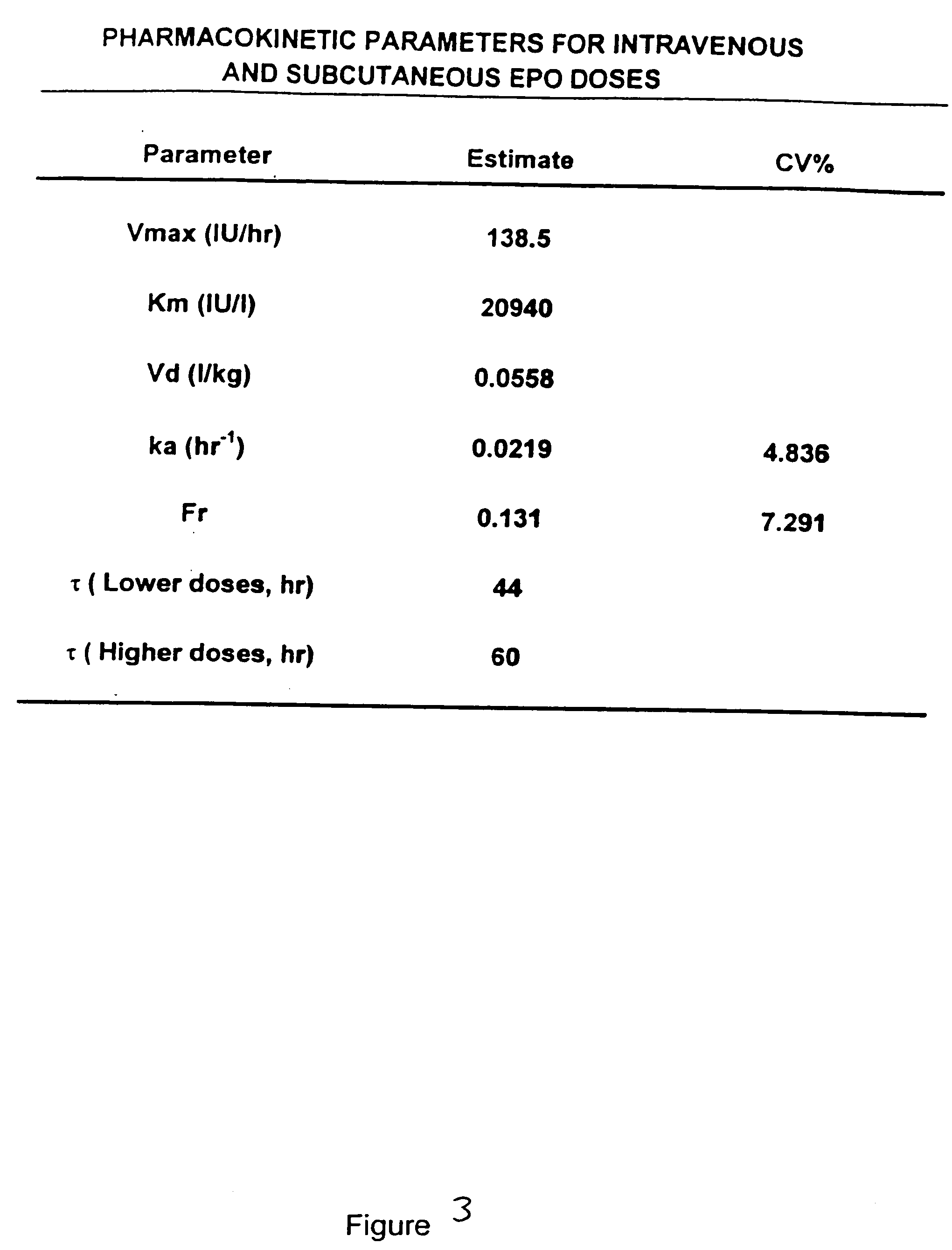

Pharmacokinetic and pharmacodynamic modeling of erythropoietin administration

InactiveUS20060128624A1Promote maturityOrganic active ingredientsPeptide/protein ingredientsDosing regimenKinetic curve

The present invention relates to systems and methods for obtaining optimized EPO dosage regimens for a desired pharmacodynamic / pharmacokinetic response. The system includes choosing one or more EPO dosage regimens, then using a PK / PD model to determine the pharmacodynamic / pharmacokinetic profile of one or more EPO dosage regimens, and finally selecting one of the EPO dosage regimens for administration to achieve the desired pharmacodynamic / pharmacodynamic response based on the EPO profile.

Owner:CHEUNG WING +3

Blast furnace furnace-front molten iron titanium removing method

The invention provides a blast furnace furnace-front molten iron titanium removing method comprising the steps that titanium remover is added into the molten iron of an iron tap channel of a blast furnace, then the molten iron falls to arrive into a torpedo ladle to be stirred, and titanium removing reaction is conducted on the molten iron; and the matching-in speed of the titanium remover is 1-3kg / s. Through the blast furnace furnace-front molten iron titanium removing method, the existing production mode and procedures are changed, the titanium remover can be evenly added into the iron tapchannel of the blast furnace, after added, the titanium remover provides kinetic reaction through molten iron flowing and falling, thus the titanium remover and the molten iron are fully mixed, reaction can be fully conducted, titanium removing efficiency is high, and field adaptability is high.

Owner:SHOUGANG CORPORATION

Method to diagnose and measure vascular drainage insufficiency in the central nervous system

InactiveUS8571634B2Increased post-stimulus undershootHigh activitySensorsBlood flow measurementDiseaseNervous system

Neurodegenerative diseases, such as multiple sclerosis, may be caused or aggravated by insufficient venous draining from the central nervous system. Functional MRI measures the surge of blood flow into localized regions of cerebral cortex in response to activation of those regions by performing visual, auditory or executive tasks. These fMRI measurements are based on blood-oxygen-level dependence. The resulting fMRI / BOLD data is converted to hemodynamic response data and analyzed to determine any abnormality in the hemodynamic response data. Vascular drainage insufficiency is identified in the presence of abnormal hemodynamic response data. Abnormal hemodynamic response data can be determined by a negative trough in a graph of the HDR data or by the duration, depth, or area of the negative trough.

Owner:HUBBARD DAVID R

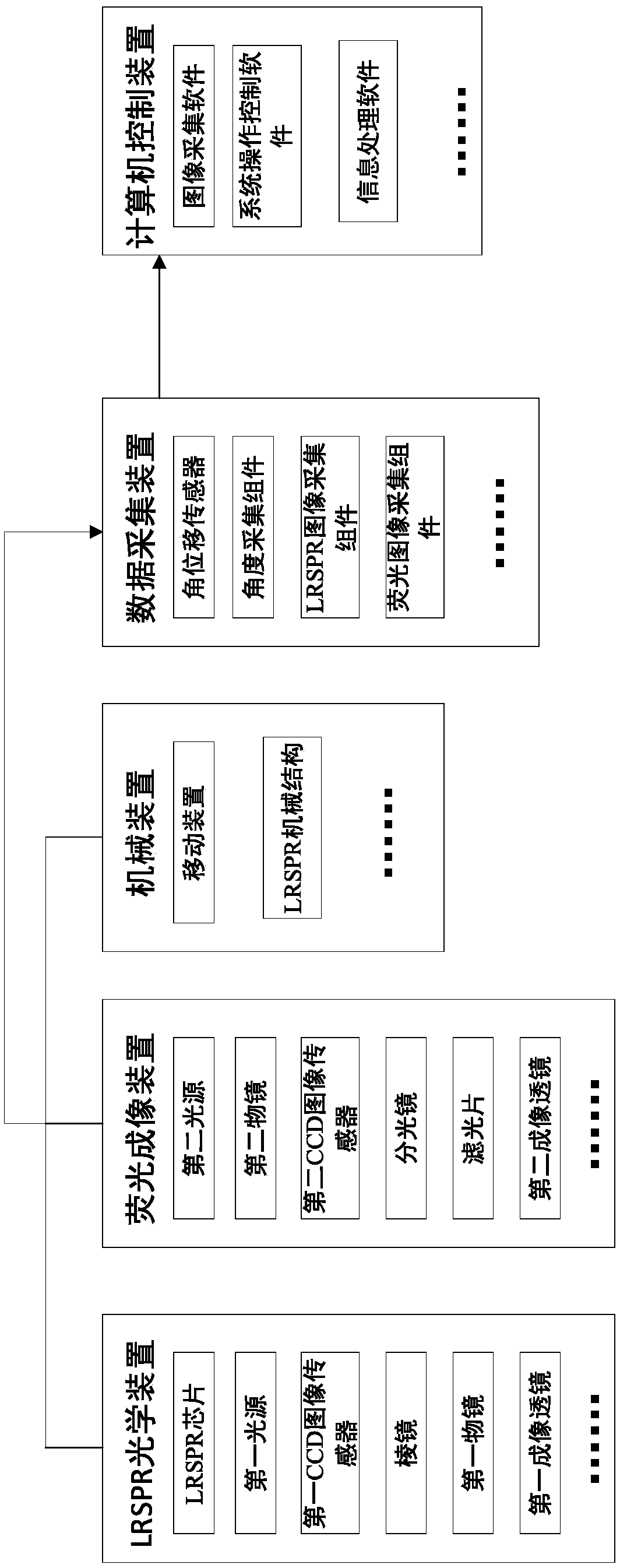

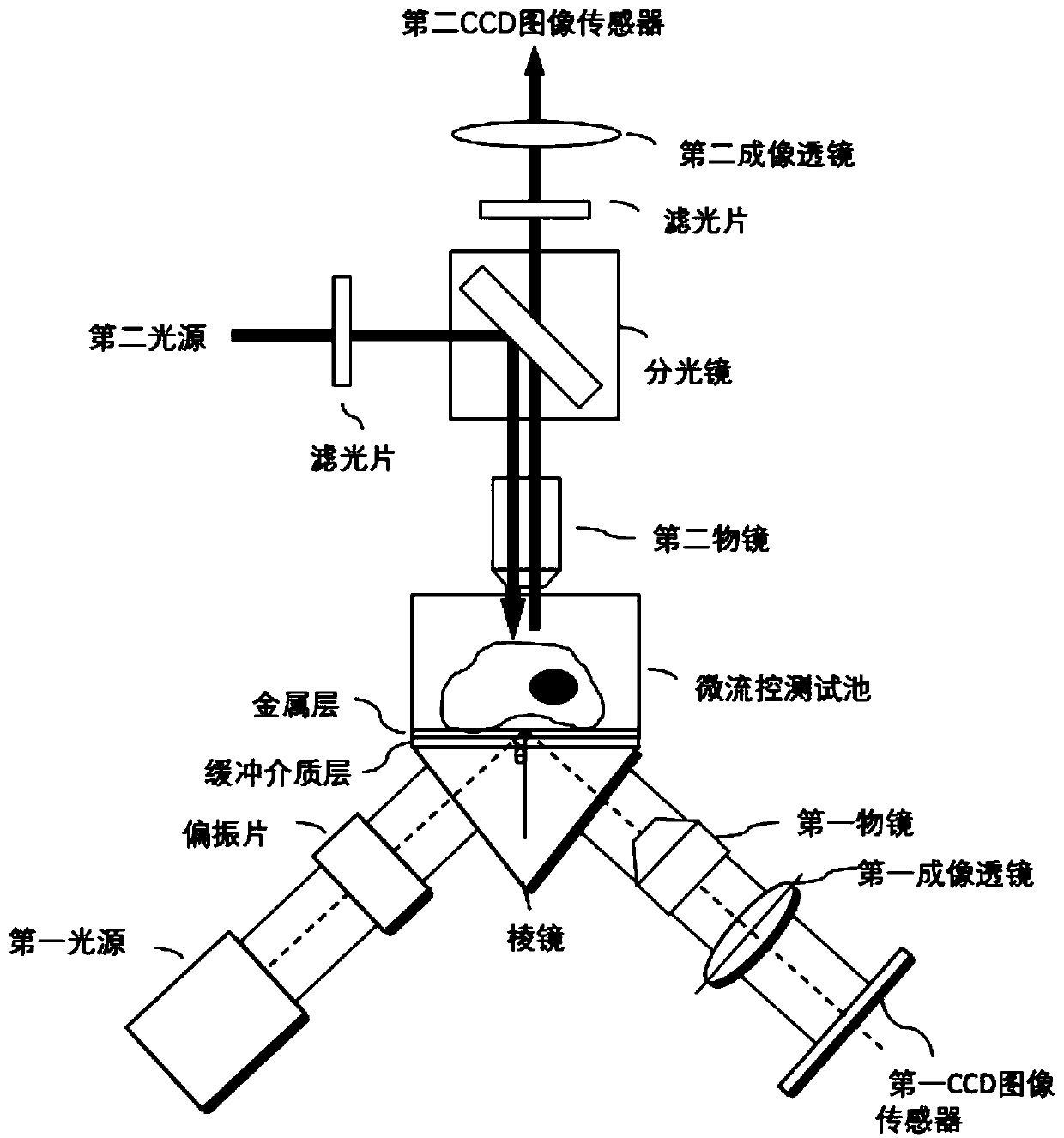

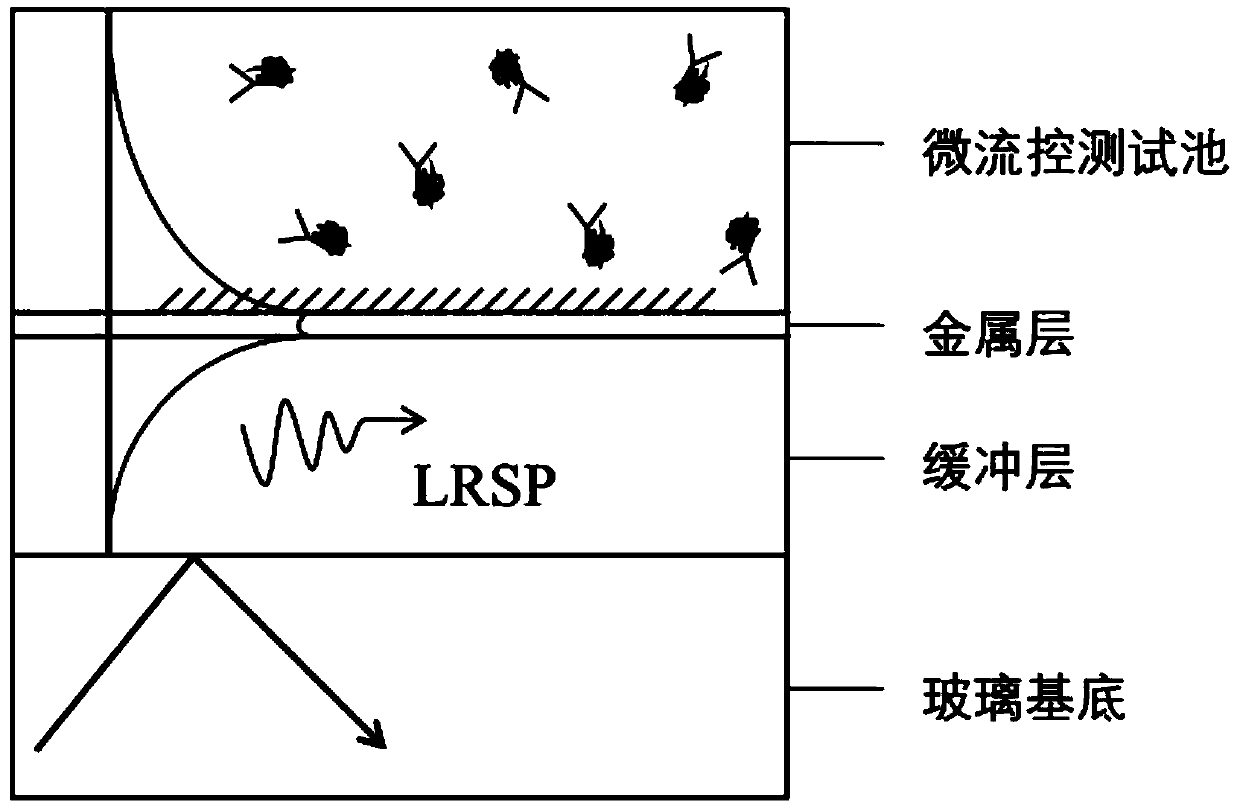

LRSPR-fluorescence imaging parallel detection device and LRSPR chip manufacturing method

ActiveCN109632721AEnhanced detection signalWide choiceFluorescence/phosphorescenceResonanceData acquisition

The invention provides an LRSPR-fluorescence imaging parallel detection device, which comprises an LRSPR optical device, a fluorescence imaging device, a mechanical device, a data collection device and a computer control device, wherein the LRSPR optical device or the fluorescence imaging device is used for generating resonance and exciting a sample to be tested to emit fluorescence signals; the fluorescence imaging device is used for detecting the fluorescence signals of the sample to be tested; the mechanical device is used for supporting and regulating the LRSPR optical device and the fluorescence imaging device; the data collection device is used for collecting operation data of the LRSPR optical device, the fluorescence imaging device and the mechanical device; and the computer control device is used for processing the operation data collected by the data collection device. The LRSPR is combined with a fluorescence imaging technology; the fluorescence detection signals can be enhanced by using the evanescent field of the LRSPR; the reaction sites of change in molecules or cells can be specifically found; and more comprehensive quantitative information and kinetic reaction process can be provided for biochemical reaction.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Method for quickly preparing silver/polypyrrole composite sol by adopting microwave method

The invention discloses a method for quickly preparing silver / polypyrrole composite sol. An oxidation-reduction reaction between a silver salt and a pyrrole monomer is a simple and effective method for preparing a silver / polypyrrole composite material, but has the defect of low dynamic reaction speed. In the invention, a method for adding a microwave external field irradiation solution into a reaction system is provided, so that the reaction speed is effectively increased, and the silver / polypyrrole composite sol is formed within 15-270 minutes.

Owner:EAST CHINA UNIV OF SCI & TECH

Calcium-carbonate-containing calcium oxide-based manganese alloy dephosphorization slag, preparation and application method of the same

The invention relates to a calcium-carbonate-containing calcium oxide-based manganese alloy dephosphorization slag. The calcium-carbonate-containing calcium oxide-based manganese alloy dephosphorization slag comprises the following components in parts, by weight: 15-30 parts of calcium oxide,15-30 parts of manganese oxide, 35-45 parts of sodium carbonate, and 15-30 parts of fluorite, wherein the particle size D50 of the calcium oxide, the manganese oxide, the sodium carbonate and the fluorite is less than or equal to 10 mm; the preparation method of the dephosphorization slag comprises the following steps that pre-melting treatment on a mixed material is carried out, heating is carried out to 1000-1200 DEG C, and the temperature is kept for 30-50 minutes, the molten slag is poured out, andnaturally cooling is carried out; crushing and screening are carried out on the slag which is cooled to the room temperature, and finally the dephosphorization slag with the particle size smaller than or equal to 5 mm is obtained; and the application method of the dephosphorization slag is provided, when the manganese alloy is smelted, the preheated dephosphorization slag is added in multiple times. The preparation and the application method have the beneficial effects that effects of dephosphorization in the slag is stabilized through the dephosphorization slag, the gas generated by decomposition of the sodium carbonate can play a role in stirring and removing phosphorus slag at the same time, and a kinetic reaction condition is increased, the dephosphorization melting point of the manganese oxide and the fluorite is reduced, the liquidity of the dephosphorization slag is improved, and the better dynamic condition is provided for the dephosphorization.

Owner:ANGANG STEEL CO LTD

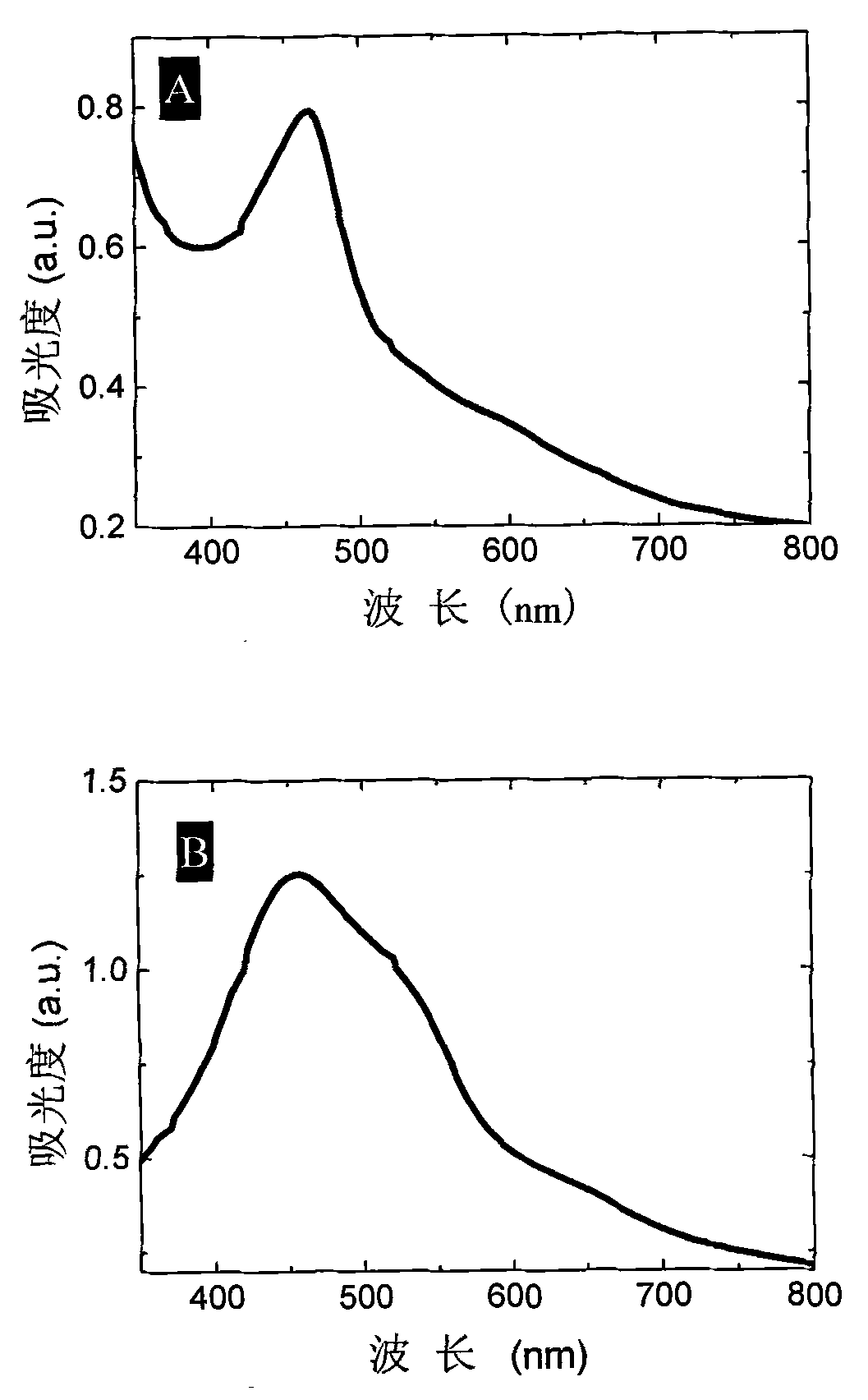

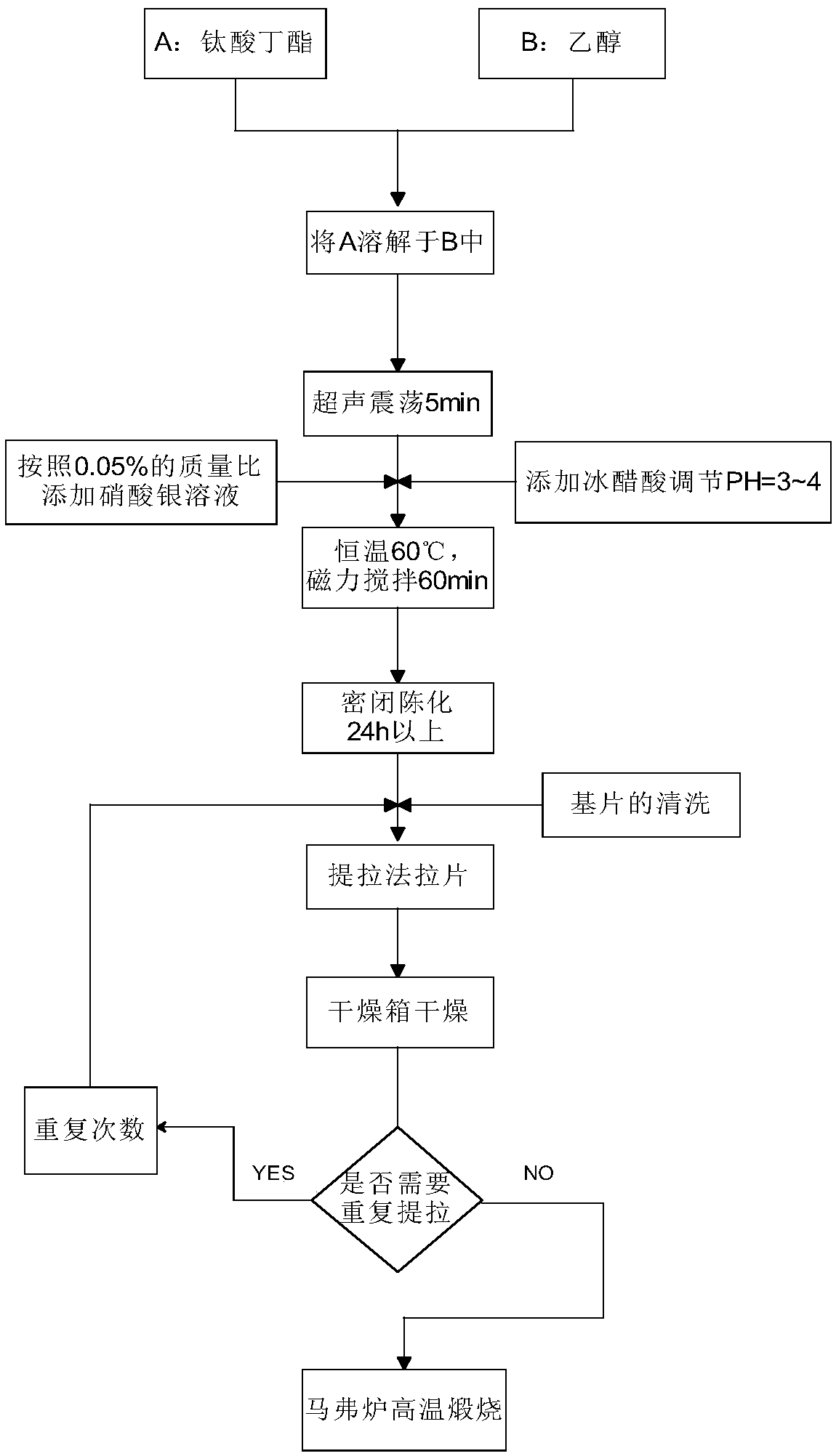

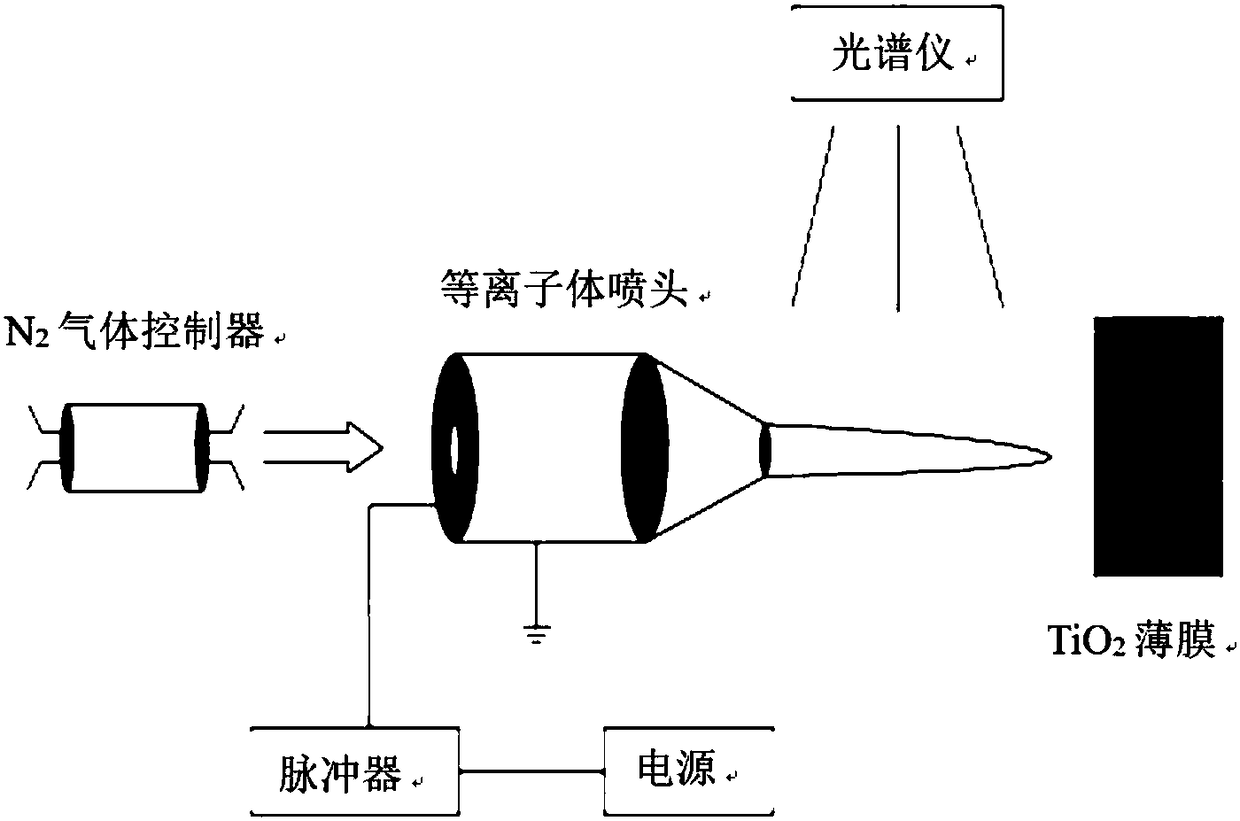

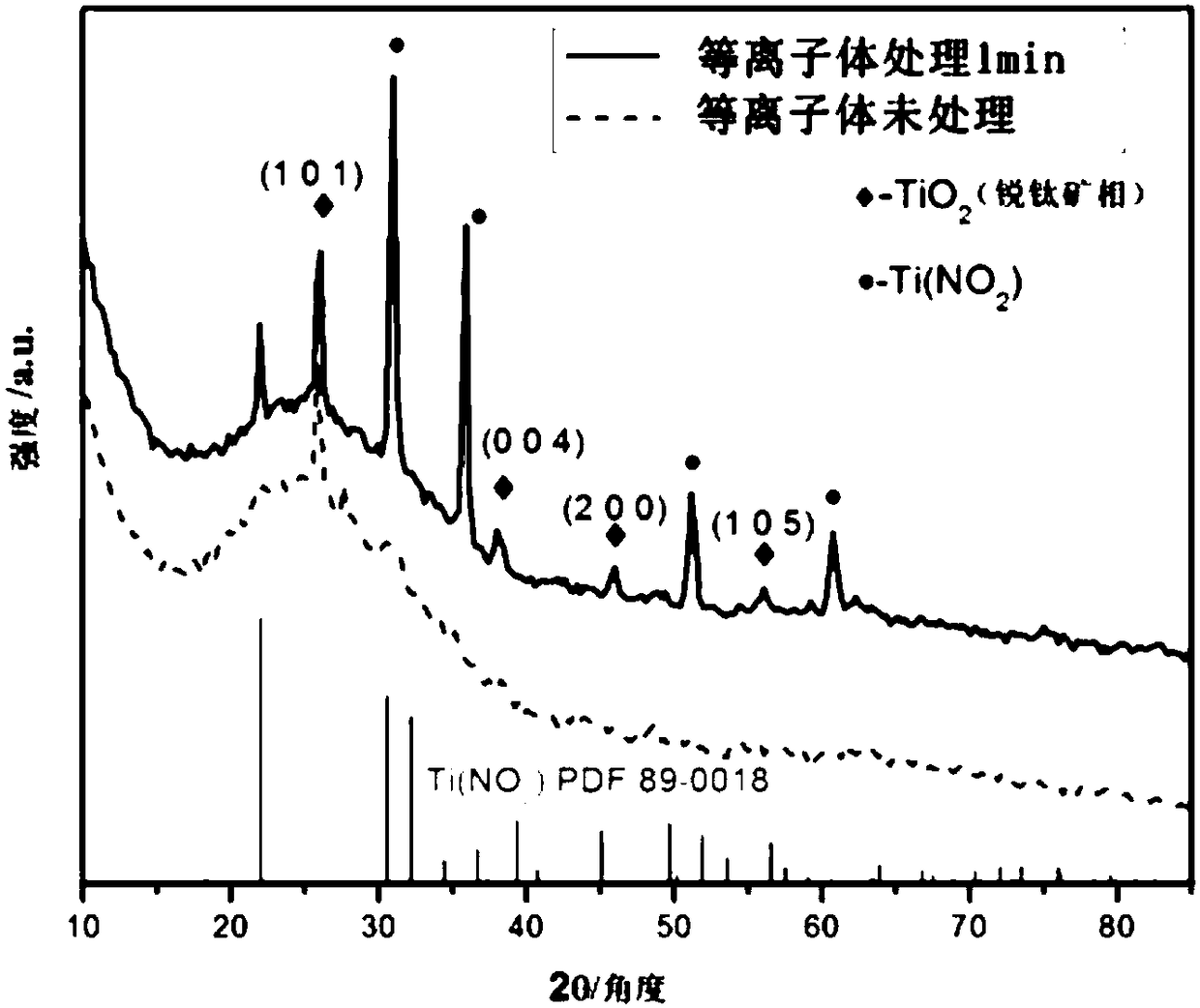

Ag-TiO2/Ti(NO2)/ITO photoelectrode, photoelectric synergistic catalytic reaction apparatus and application of photoelectric synergistic catalytic reaction apparatus

InactiveCN108355470AEasy reunionSolve the disadvantages of difficult recyclingFruit and vegetables preservationDispersed particle separationQuantum efficiencyElectricity

The invention belongs to the field of fruit fresh keeping and storage, and discloses Ag-TiO2 / Ti(NO2) / ITO photoelectrode, a photoelectric synergistic catalytic reaction apparatus based on the Ag-TiO2 / Ti(NO2) / ITO photoelectrode and application of the photoelectric synergistic catalytic reaction apparatus. A Ag-TiO2 / Ti(NO2) / ITO system is used as a photoelectrode, a TiO2 film is doped and modified byvirtue of Ag, then the plasma treatment is performed at the atmosphere pressure of N2, N is in site doped to form a novel phase, a semiconductor photocatalytic oxidation method and an electrochemicalmethod are combined to produce a synergistic effect, so that the quantum efficiency of the catalytic process can be significantly increased, when the photoelectrode synergistic catalytic reaction apparatus is applied to the fresh keeping of fruits, the effect is apparently improved compared with the single photocatalytic effect and the single electric catalytic effect, and a monopolar dynamics reaction rate constant of the C2H4 photoelectric synergistic catalytic degradation is increased from the 6.86*10<-4>(min<-1>) with no voltage to 9.06*10<-4>(min<-1>) and is increased by 32 percent.

Owner:SOUTH CHINA AGRI UNIV

Small scale ideal kinetic reactor to evaluate full size industrial catalysts

InactiveUS20060148089A1Fast experiment turnaroundEnhanced informationTesting starch susbtancesChemical analysis using catalysisPtru catalystProcess engineering

Owner:FREESLATE

Experiment and analysis method of insulation life of power supply cable polymer material

InactiveCN105973745AAvoid fireGuarantee the safety of life and propertyWeighing by removing componentEngineeringFailure index

The invention provides an experimental method and analysis of the insulation life of the polymer material of the power supply cable, including: weighing the cable to be tested; determining the failure index of the cable, and the failure index is: 10% of the weight loss of the cable is failure; In the instrument, measure the absolute temperature when the cable under test fails at different heating rates; according to the pyrolysis kinetics reaction rate equation and the Amhenius equation, establish the corresponding functional relationship between the service life t of the cable under the service temperature and the service temperature T , that is, the service life t of the cable under the condition of service temperature T; the cable is a polymer insulating material. Using the experimental method of the invention can realize the life experiment, and by establishing and analyzing the corresponding function relation between t and T, the service life of the cable under the service temperature condition can be obtained. This is crucial to correctly assessing and predicting the aging and life of the line, avoiding circuit fires, and ensuring the safety of life and property of the country and people.

Owner:SHANDONG UNIV

Pharmacokinetic and pharmacodynamic modeling of erythropoietin administration

InactiveUS20060100150A1Promote maturityOrganic active ingredientsPeptide/protein ingredientsDosing regimenKinetic curve

The present invention relates to systems and methods for obtaining optimized EPO dosage regimens for a desired pharmacodynamic / pharmacokinetic response. The system includes choosing one or more EPO dosage regimens, then using a PK / PD model to determine the pharmacodynamic / pharmacokinetic profile of one or more EPO dosage regimens, and finally selecting one of the EPO dosage regimens for administration to achieve the desired pharmacodynamic / pharmacodynamic response based on the EPO profile.

Owner:CHEUNG WING +3

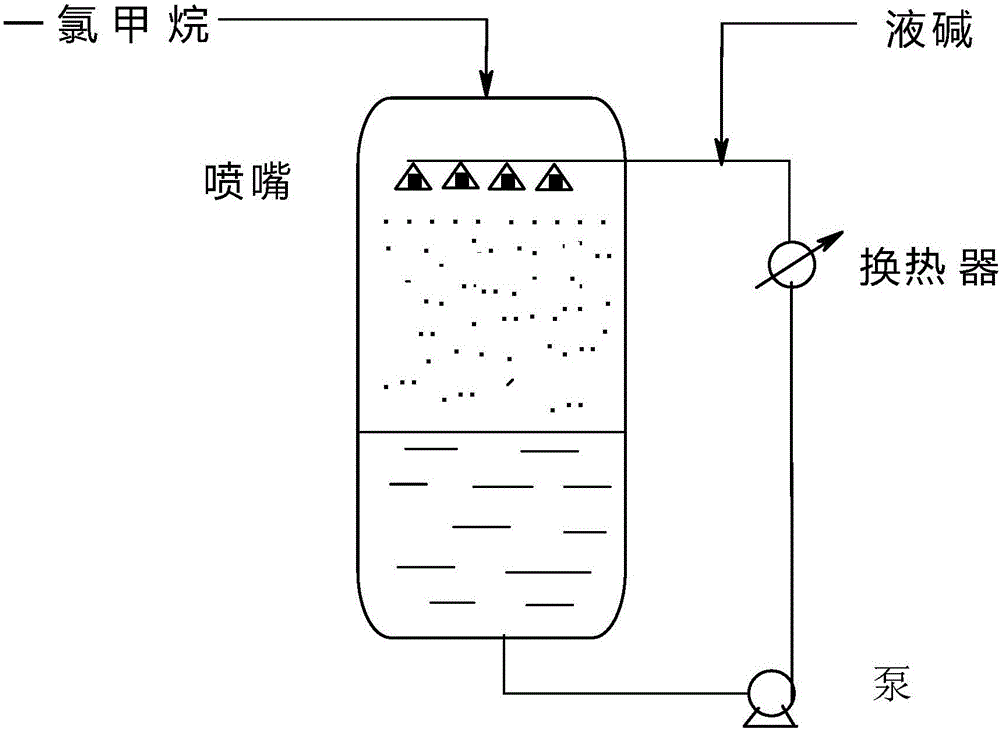

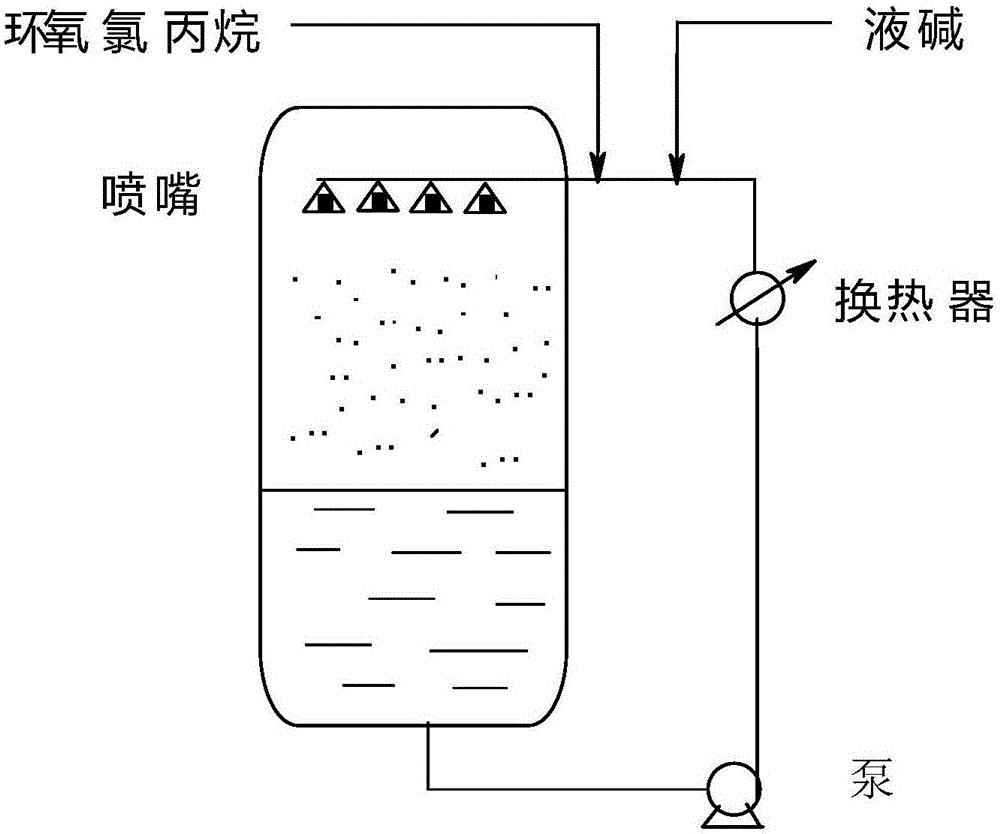

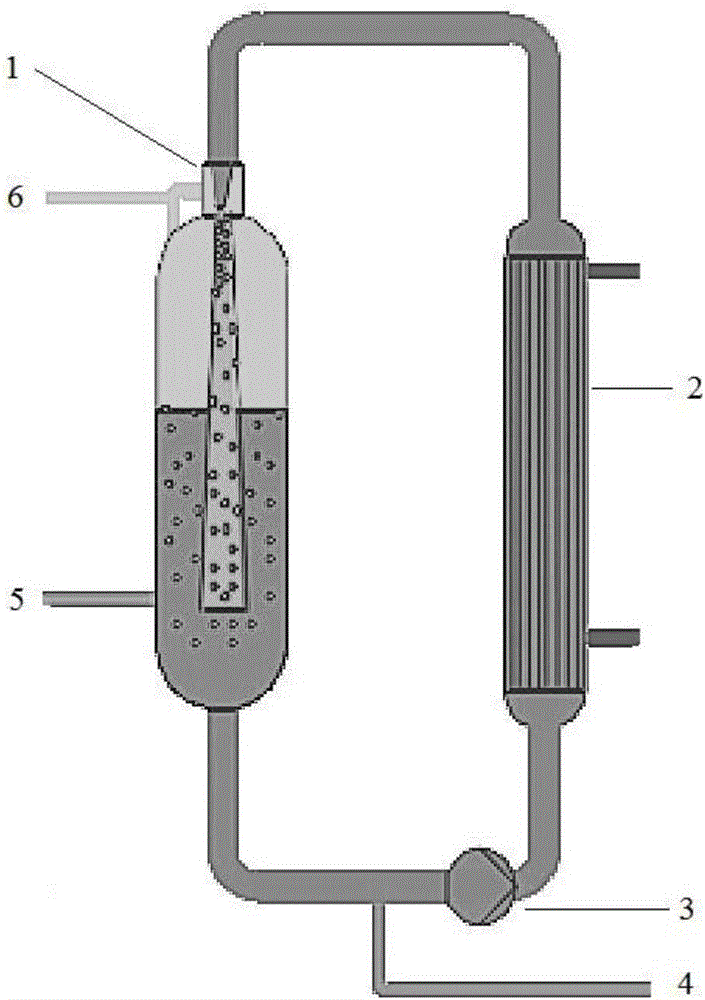

Preparation method of methyl-terminated propenol polyether

The invention discloses a preparation method of methyl-terminated propenol polyether. The preparation method includes: adding a propenol polyoxyethylene ether raw material into an external-circulating spray-type reactor for deoxidizing, nitrogenizing, replacement and protection; starting an external circulating pump for high-speed circulating spraying, controlling reaction temperature to 0-60 DEG C, and spraying a liquid alkali raw material into the reactor; slowly adding a methane chloride raw material, and sufficiently mixing for reaction. The system belongs to dynamic control systems, side reaction is sufficiently inhibited, and a low-temperature method is further adopted to control dynamic reaction according to the characteristic that the side reaction is high in activation energy, so that hydrolysis reaction of methane chloride is inhibited, allyl isomerization reaction is further inhibited, the reaction system is higher in selectivity, and color of methyl-terminated propenol polyether which is finally obtained is lower than 30 while terminating rate is higher than 98%.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL +1

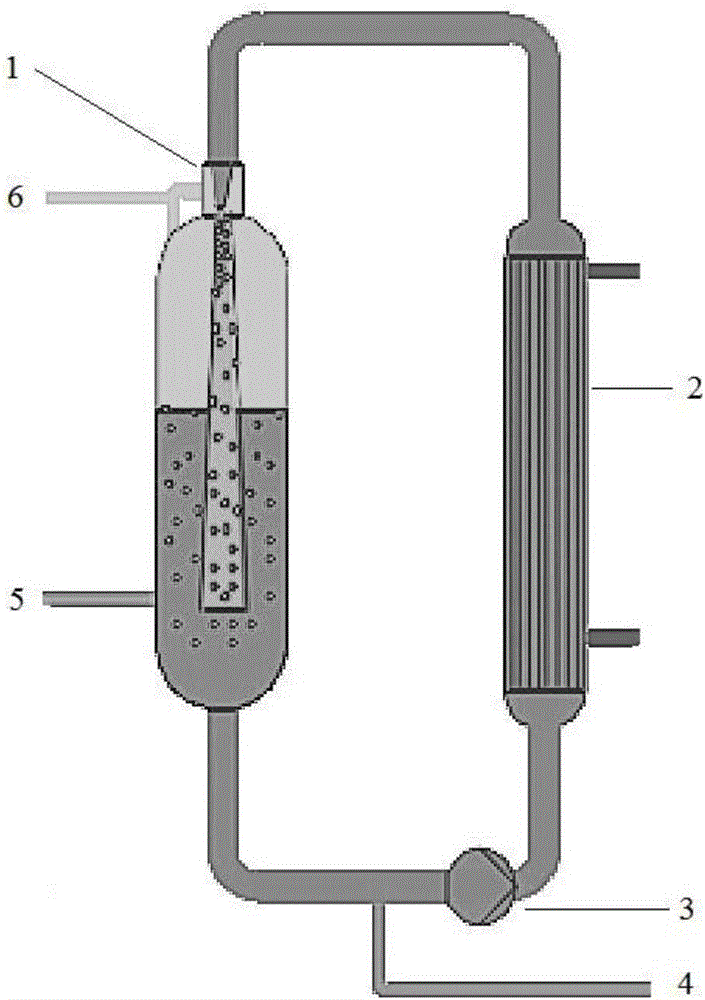

Novel method for terminating allyl alcohol irregular polyether methyl

InactiveCN106565949AIncrease mass transfer rateIncreased mass transfer rates over conventional stirred tank reactorsEther preparation by ester reactionsIsomerizationKinetic control

The invention discloses a novel method for terminating allyl alcohol irregular polyether methyl. The novel method comprises the following steps of: adding allyl alcohol irregular polyether raw materials through a material inlet in a jetting loop reactor based on Venturi effect, deoxidizing and introducing inert gases for replacement and protection, and starting an external circulating pump to carry out high-speed jetting mixing; and at a control temperature ranging from 20 DEG C to 70 DEG C, slowly adding a methane chloride raw material and an alkali raw material into the jetting loop reactor through a methane chloride raw material feeding hole and a material feeding hole separately, and the like. According to the novel method disclosed by the invention, this system belongs to a dynamic control system, side reactions are restrained sufficiently, a low-temperature method is further adopted to carry out dynamic reaction control according to the characteristic that activation energy of side reactions is high, hydrolysis reaction of methane chloride is restrained, and isomerization reaction of allyl is further restrained, and therefore, selectivity of a reaction system is higher. Finally obtained allyl alcohol irregular polyether methyl terminated product has color and luster smaller than 30, and has a terminating rate greater than 98%.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

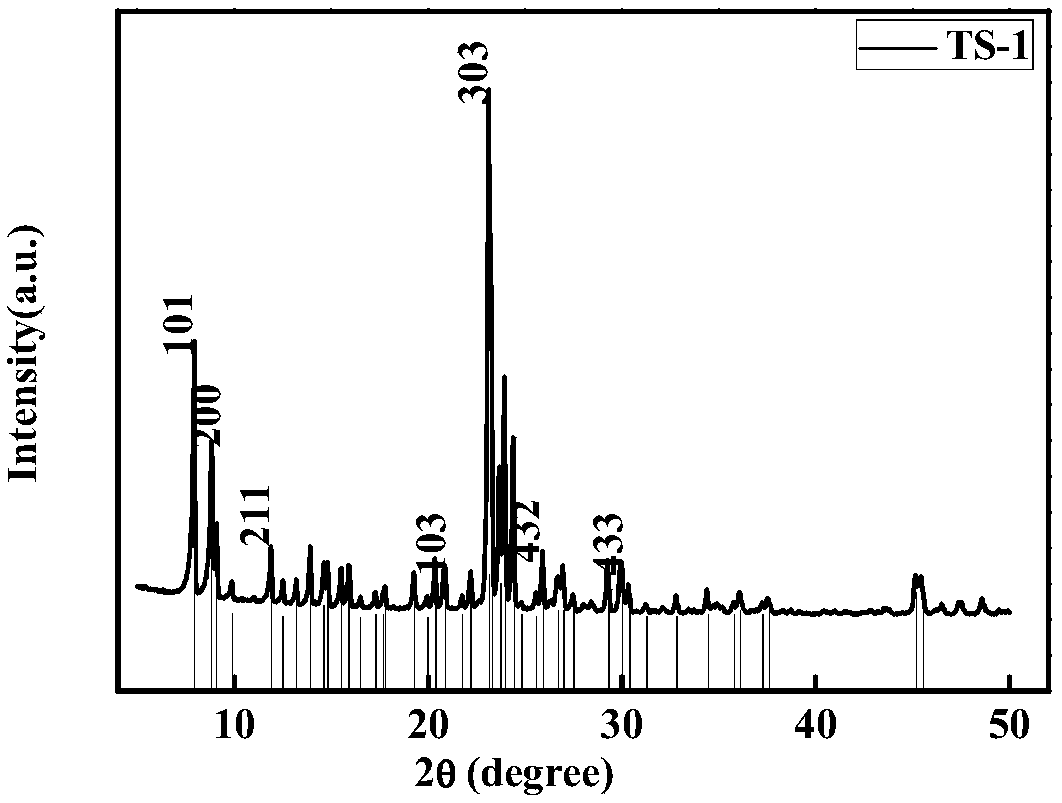

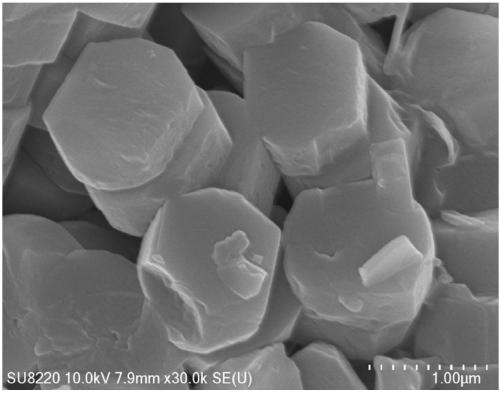

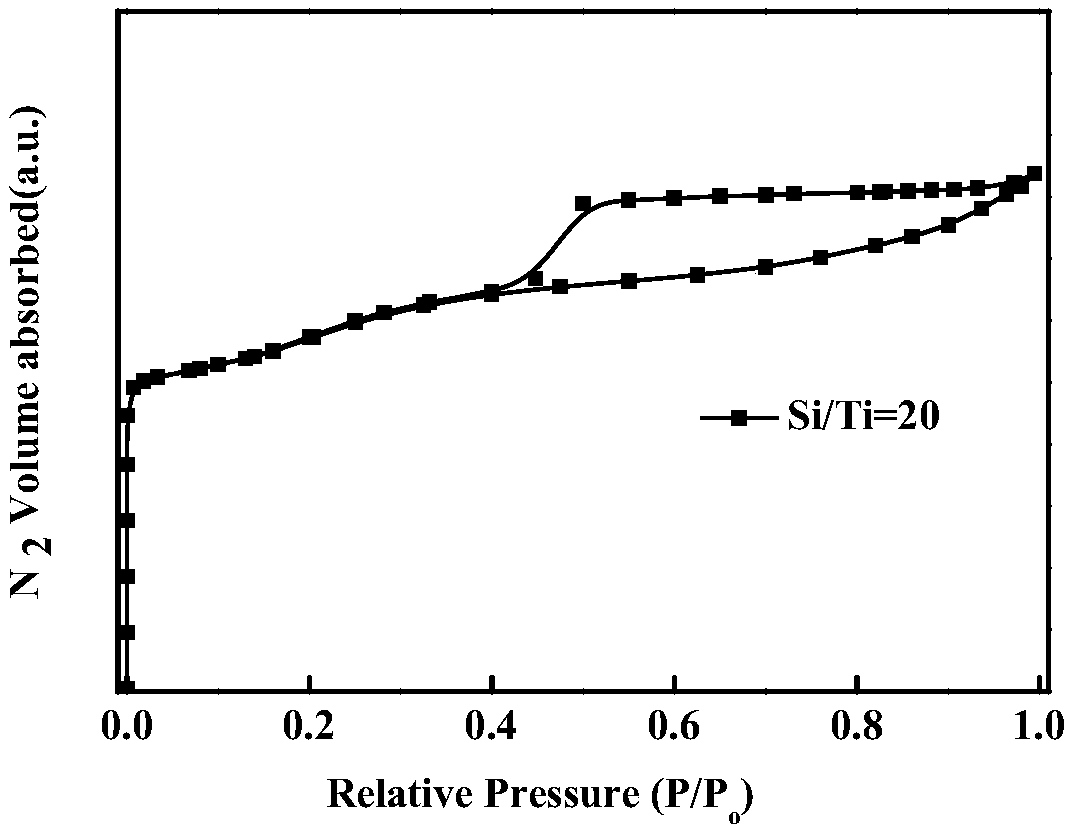

Hierarchical porous titanium-silicon molecular sieve catalyst with oxidative desulfurization function and preparation method and application thereof

ActiveCN109482229AEasy to prepareShorten the timeOrganic chemistryMolecular sieve catalystsSulfideHigh pressure

The invention belongs to the technical field of molecular sieves and preparation thereof and discloses a hierarchical porous titanium-silicon molecular sieve catalyst with an oxidative desulfurizationfunction and a preparation method and application thereof. The preparation method includes the steps of mixing tetrapropylammonium hydroxide and deionized water, dropwise adding ethyl silicate and butyl titanate, and stirring; transferring the mixture to a stainless steel high-pressure kettle, and drying in a drying box at 180 DEG C in static state; separating by centrifuging, washing, and dryingovernight in an oven at 80 DEG C to obtain a molecular sieve; mixing the molecular sieve, sodium hydroxide, water and aspartic acid, stirring at room temperature, filtering by centrifuging, drying the filter residue in the oven at 80 DEG C for 10 hours, taking out, and calcining in a muffle furnace for 6 hours at a temperature rate of 2 DEG C / min from room temperature to 550 DEG C to obtain the catalyst herein. The molecular sieve catalyst of Si / Ti=20 is up to 43% in conversion rate 4 hours after sulfide removal; dynamics simulation of the catalyst shows that the reaction is first-order dynamics reaction.

Owner:GUANGDONG UNIV OF TECH

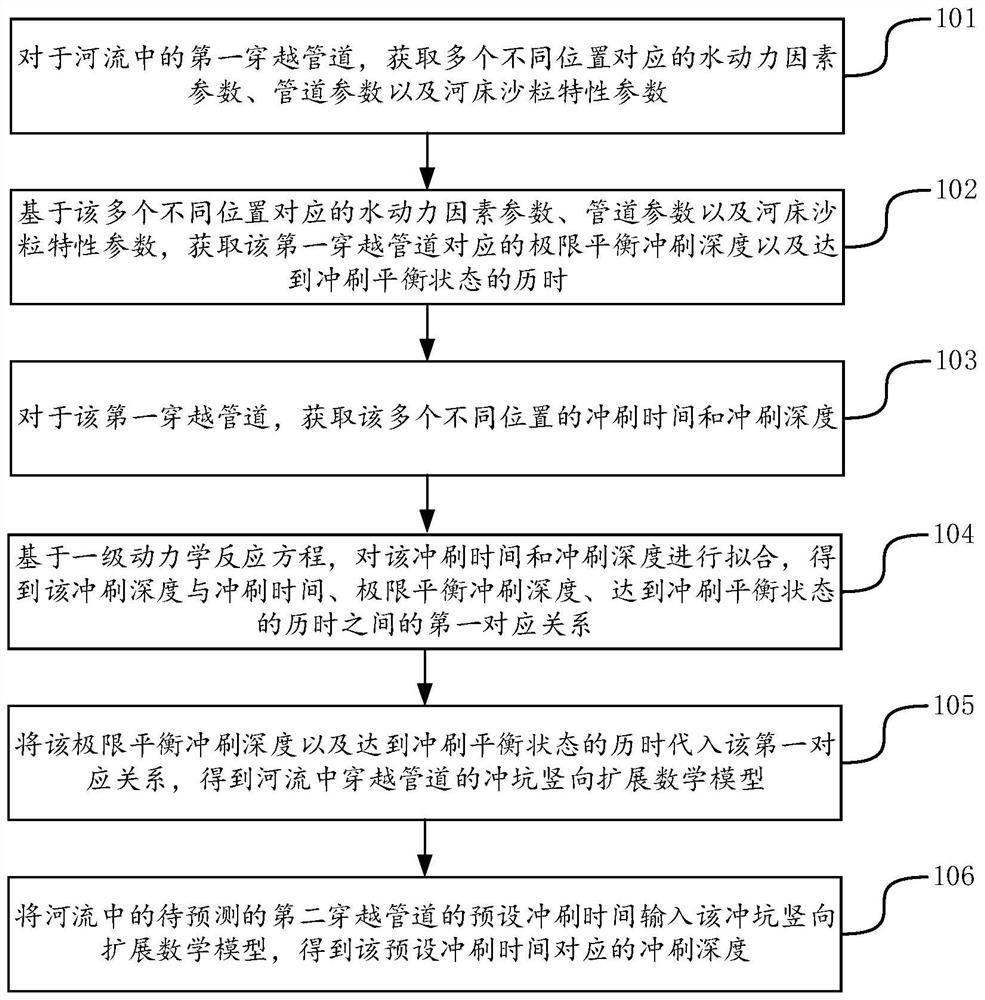

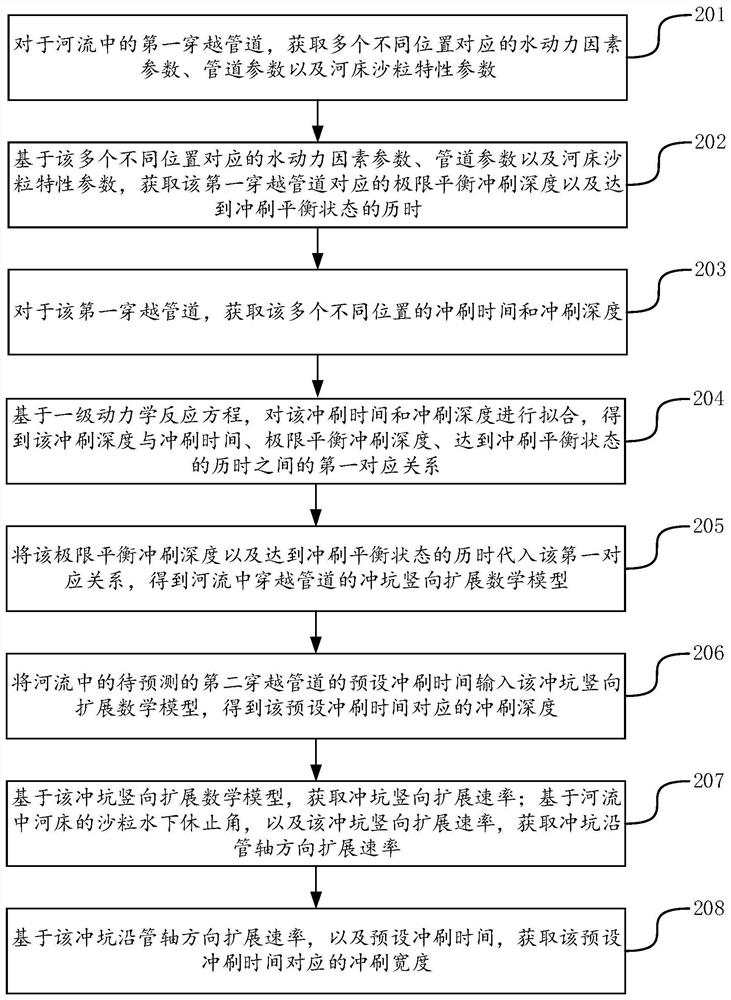

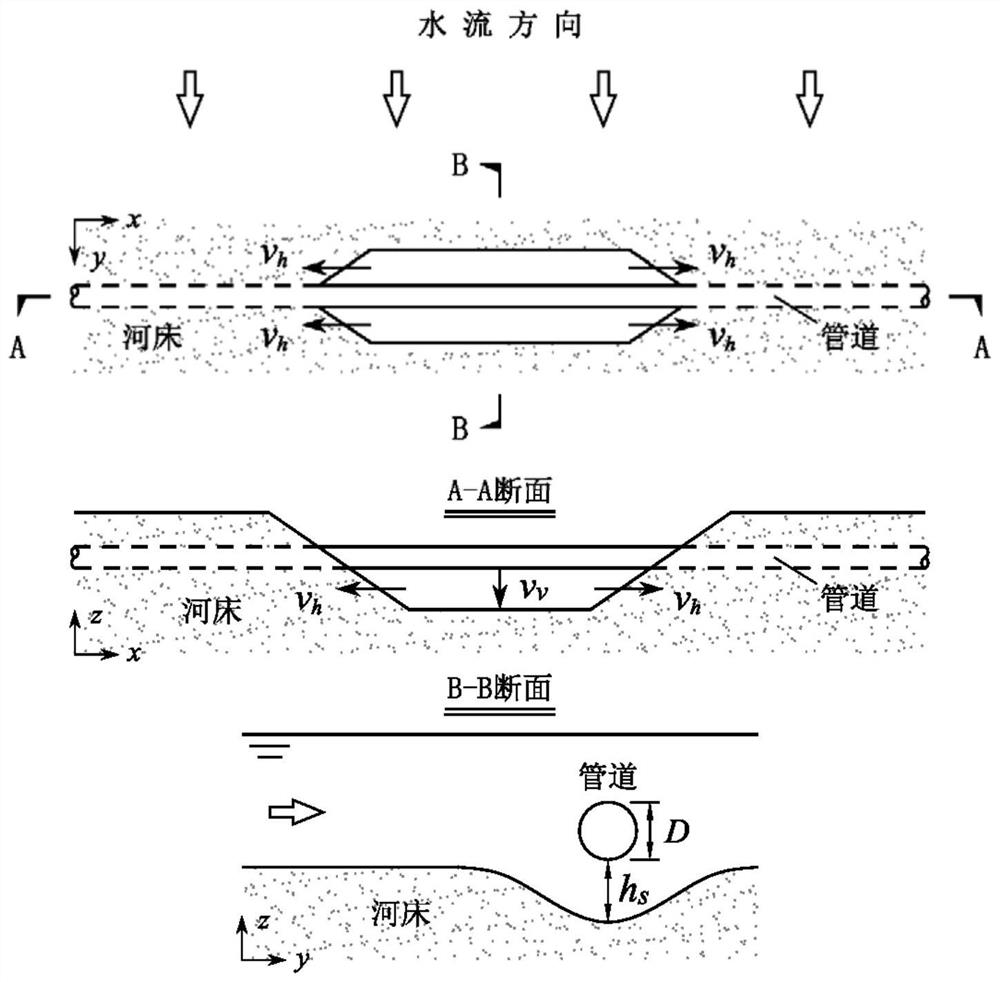

Method and device for predicting bottom scouring depth of underwater crossing pipeline

ActiveCN114065654ATimely reinforcementImprove securityDesign optimisation/simulationMarine engineeringMathematical model

The invention provides a method and device for predicting the bottom scouring depth of an underwater crossing pipeline, and belongs to the technical field of underwater crossing pipelines. According to the technical scheme provided by the embodiment of the invention, the corresponding limit equilibrium scouring depth and the duration of reaching the scouring equilibrium state are obtained based on the various characteristic parameters of the first crossing pipeline which is scoured in the river; and the data are obtained based on the actual scouring data, so that the reliability is relatively high, and the accuracy is high. According to the data, the scouring time and the scouring depth of the first crossing pipeline and the first-level kinetic reaction equation, a scouring pit vertical expansion mathematical model of the crossing pipeline in the river can be obtained, and the model can reflect the rule that the scouring pit depth changes along with the scouring time. Based on the mathematical model, the scouring depth of the to-be-predicted second crossing pipeline at any preset scouring time can be obtained, so that a riverbed can be reinforced in time, and the safety and reliability of the underwater crossing pipeline are improved.

Owner:PETROCHINA CO LTD

Preparation method of allyl alcohol polyether glycidyl ether

InactiveCN106496543AEnhanced mass transferReduce the chance of occurrenceOrganic chemistryHigh activationNitrogen

The invention discloses a preparation method of allyl alcohol polyether glycidyl ether. The method comprises the following steps: in an external circulation spray reactor, adding allyl alcohol polyoxyethylene ether raw materials, carrying out deoxygenation-nitrogenization replacement protection, starting an outer circulating pump to carry out high-speed circulating spray; controlling the temperature at 10 to 55 DEG C, spraying epichlorohydrin raw materials and liquid caustic soda raw materials into the reactor to fully mix and make the allyl alcohol polyoxyethylene ether raw materials, the epichlorohydrin raw materials and the liquid caustic soda raw materials react and the like, the system belongs to a kinetic control system, and side effects are further sufficiently inhibited. In addition, according to the characteristic of high activation energy of the side effects, the preparation method of the allyl alcohol polyether glycidyl ether uses a low-temperature method to carry out kinetic reaction control, so that a reaction system is higher in selectivity. The color of the finally obtained product, namely the allyl alcohol polyether glycidyl ether is less than 40, and the capping rate of the allyl alcohol polyether glycidyl ether is greater than 96%.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL +1

Method for preparing methyl-ended butanol random polyether

InactiveCN106543429AIncrease mass transfer rateIncreased mass transfer rates over conventional stirred tank reactorsOxygenKinetic control

The invention discloses a method for preparing methyl-ended butanol random polyether. The method comprises the following steps: adding a butanol random polyether raw material into a Venturi effect-based jet loop reactor through a material inlet; removing oxygen and introducing inert gases for replacement and protection; starting an outer circulating pump for high-speed jet mixing; and controlling the temperature to be 20-80 DEG C, slowly adding a methane chloride raw material and a bas raw material respectively through a methane chloride inlet and the material inlet, and the like. The system belongs to a kinetic control system, and the side effect is sufficiently inhibited. Furthermore, according to the characteristic of high side reaction activation energy, a low-temperature method is adopted for kinetic reaction control, the hydrolysis reaction of methane chloride is inhibited, and thus the reaction system has higher selectivity. Finally, the methyl-ended butanol random polyether product has the color of less than 30 and the ending rate of more than 98 percent.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

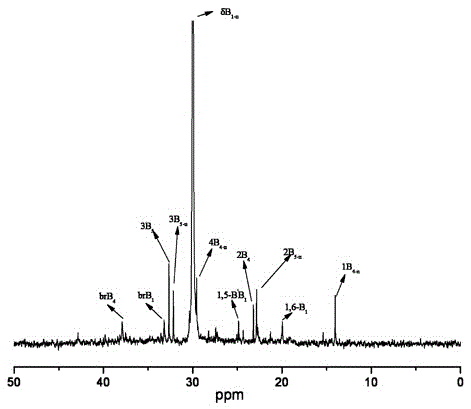

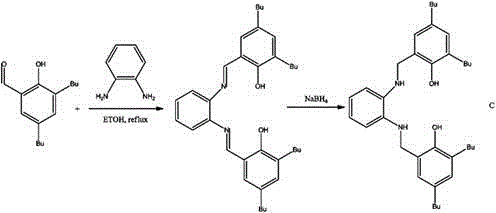

Supported bridged bis-phenoxy IVB metal catalyst and preparation method thereof

InactiveCN105646737ASolve the problem of low catalyst activityResolve low activityStructural formulaHydroxy compound

The invention discloses a supported bridged bis-phenoxy IVB metal catalyst and a preparation method thereof. The structural formula of the active component [ONNO]MX2 of the catalyst is disclosed as Formula (I) or Formula (II). The active component of the catalyst is supported on a triethyl-aluminum-modified MgCl2 / EtnAl(OR)[3-n] supporter, wherein R is C2-C5 straight-chain alkyl; and n represents the quantity of hydroxyl hydrogens substituted by triethyl aluminum in ethanol, and n=0-3. According to the characteristics of the [ONNO] bridged bis-phenoxy IVB metal catalyst framework ligand, the [ONNO] bridged bis-phenoxy IVB metal catalyst is supported on the MgCl2 / EtnAl(OR)[3-n] supporter to form a novel supported catalyst, thereby solving the problem of low activity in the homogeneous [ONNO] bridged bis-phenoxy IVB metal catalyst. The kinetic reaction of the novel supported catalyst is stable and efficient, has higher catalytic activity, and can be used for preparing branched polyethylene.

Owner:SUN YAT SEN UNIV

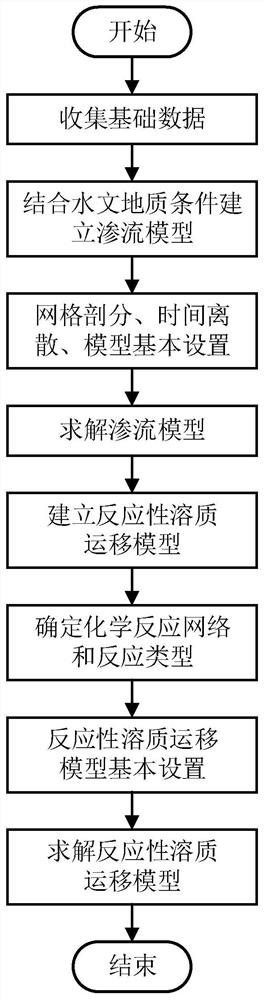

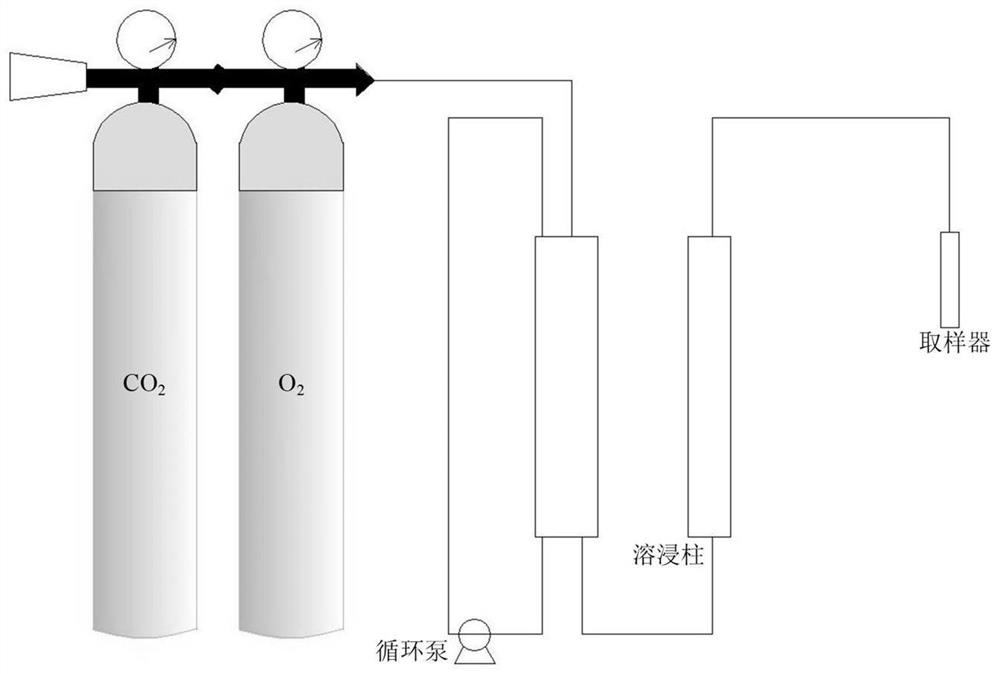

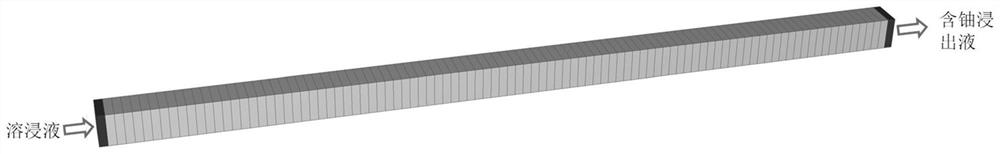

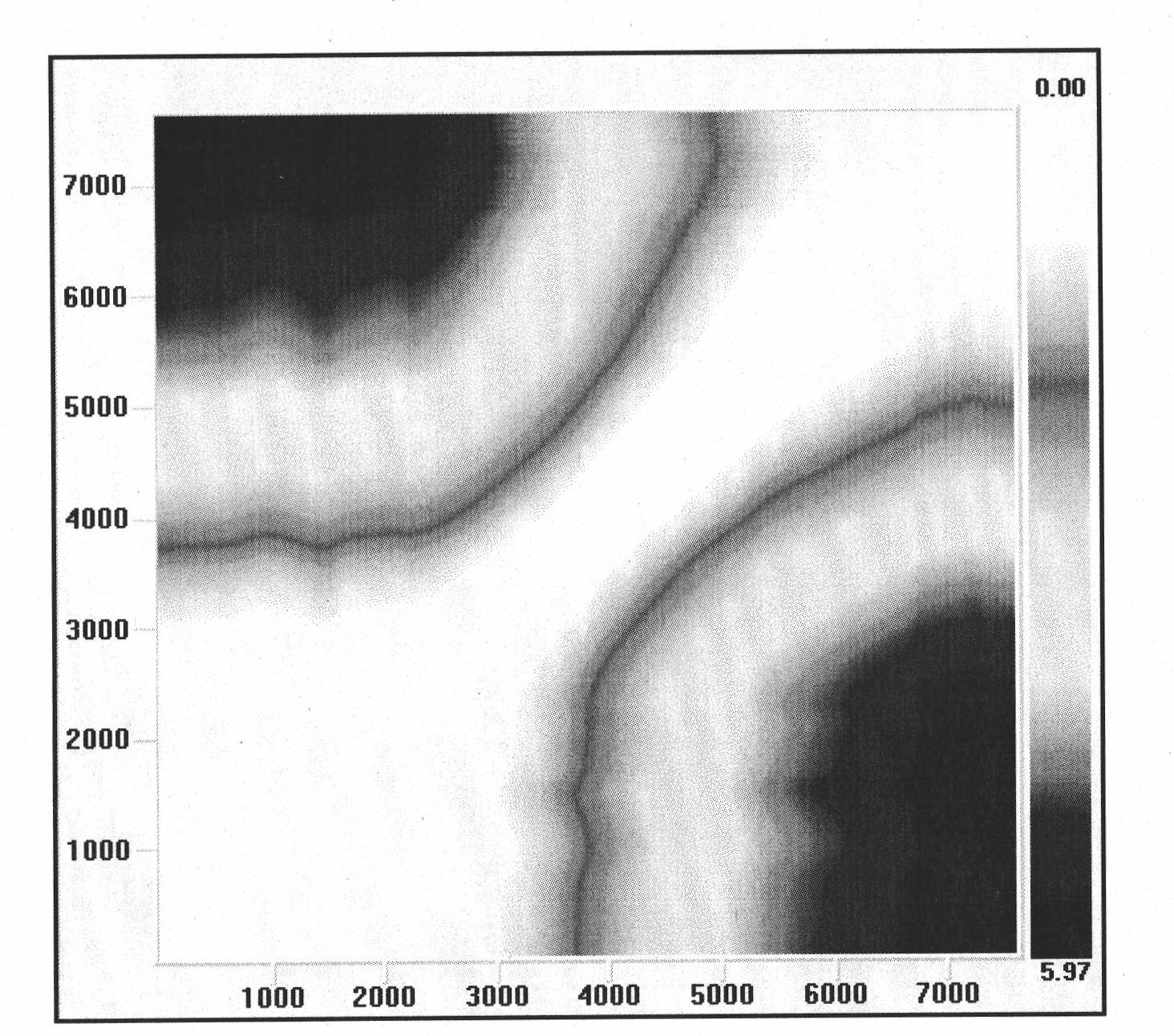

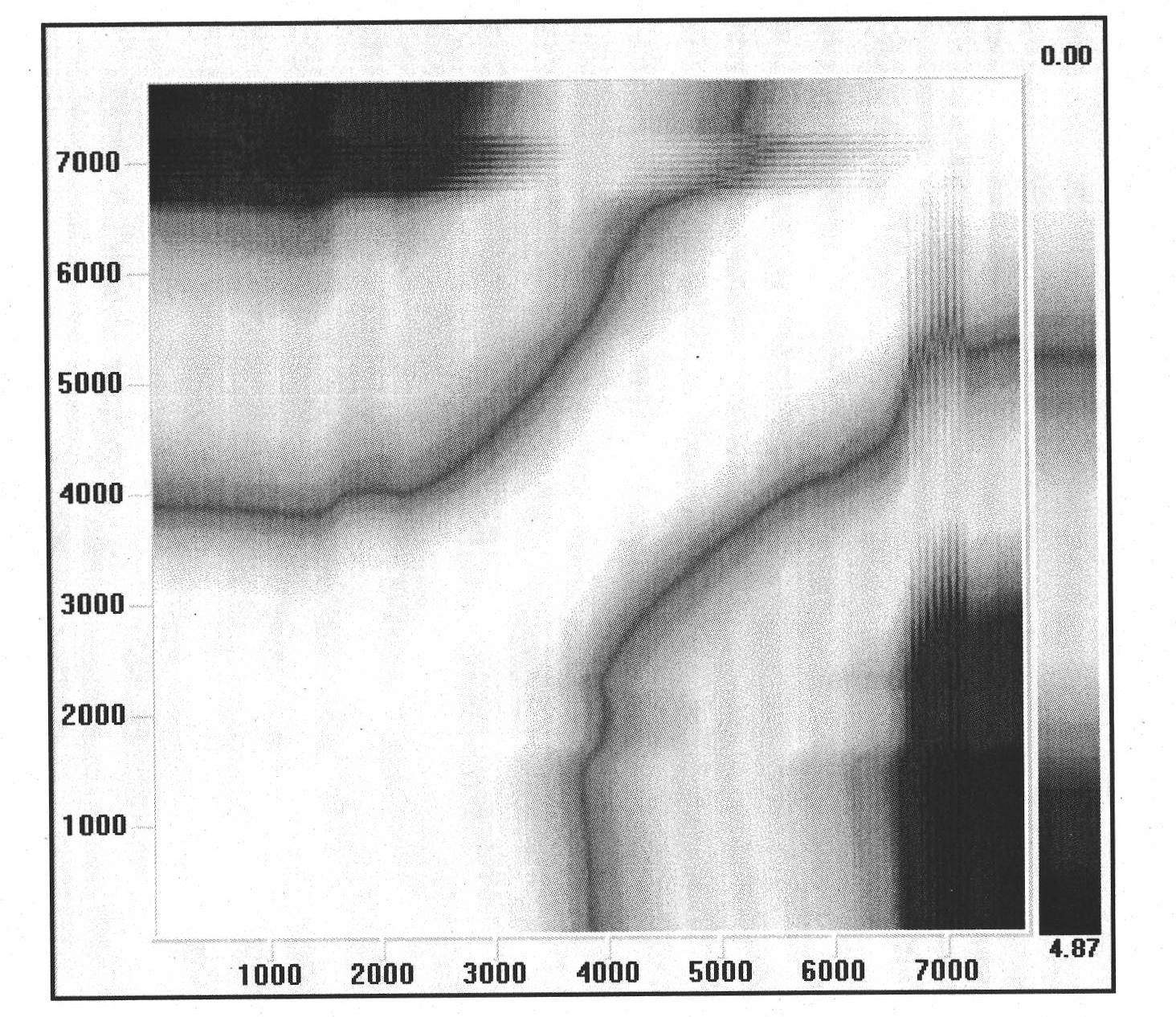

Reaction migration numerical simulation method for sandstone type uranium mine CO2+O2 in-situ leaching uranium mining

PendingCN113051843AImproving the ability of numerical simulation of in-situ leaching reaction migrationFor precise controlSeismologyProspecting/detection of underground/near-surface gasesUraniniteMining engineering

The invention discloses a reaction migration numerical simulation method for sandstone type uranium ore CO2 + O2 in-situ leaching uranium mining, which can break through the traditional in-situ leaching uranium mining solute migration numerical simulation method only considering convection and dispersion effects, and tries to establish a multi-field coupled reactive solute migration model to simulate the dynamic leaching process of northern sandstone type asphalt uranium ore. The method provided by the invention comprises the following steps: constructing a thermodynamic database suitable for the CO2 + O2 leaching process of the northern sandstone-type uranium mine, considering a uranium dissolution kinetic reaction process under the combined action of oxygen O2 (aq) and bicarbonate HCO3-, and carrying out CO2 + O2 in-situ leaching uranium mining reaction migration numerical simulation by adopting a TOUGHRECT simulation technical framework. The simulation technology provided by the invention can provide technical support for carrying out accurate simulation and dynamic adjustment and control of the mining region scale CO2 + O2 leaching process.

Owner:NANJING UNIV +2

Method for representing high-phosphorus iron ore dynamic reaction stage

The invention relates to the technical fields of metallurgical engineering and statistics, in particular relates to a method used for judging and representing a high-phosphorus iron ore reduction dynamic reaction stage. The invention is mainly applied to deconstruction of the high-phosphorus iron ore reduction dynamic reaction stage. The method comprises the following concrete steps: (1) placing a sample obtained by mixing high-phosphorus iron ore and a coal dust cosolvent on a thermogravimetry analyzer to perform a dynamic experiment; (2) extracting a differential thermal scanning calorimetric curve after the experiment is finished; (3) discretizing the curve obtained in (2) to form a time sequence, and importing the time sequence into VRA (visual recurrence analysis) software for analysis; and (4) judging the dynamic stage according to image features. The invention is applied to judging the high-phosphorus iron ore reduction dynamic stage, the method is simple and convenient and has high practical value, and a practical and reliable judging and representing method is provided for production practice and control on smelting of the high-phosphorus iron ore.

Owner:KUNMING UNIV OF SCI & TECH

Method for representing high-phosphorus iron ore dynamic reaction stage

Owner:KUNMING UNIV OF SCI & TECH

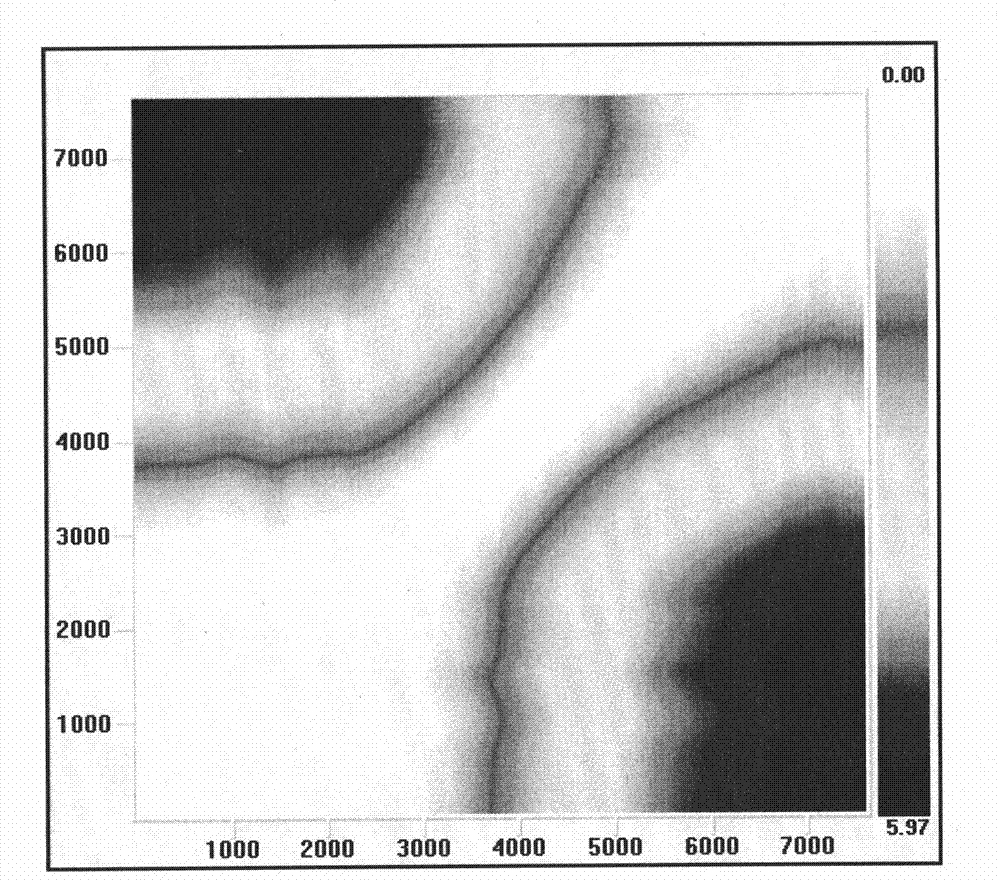

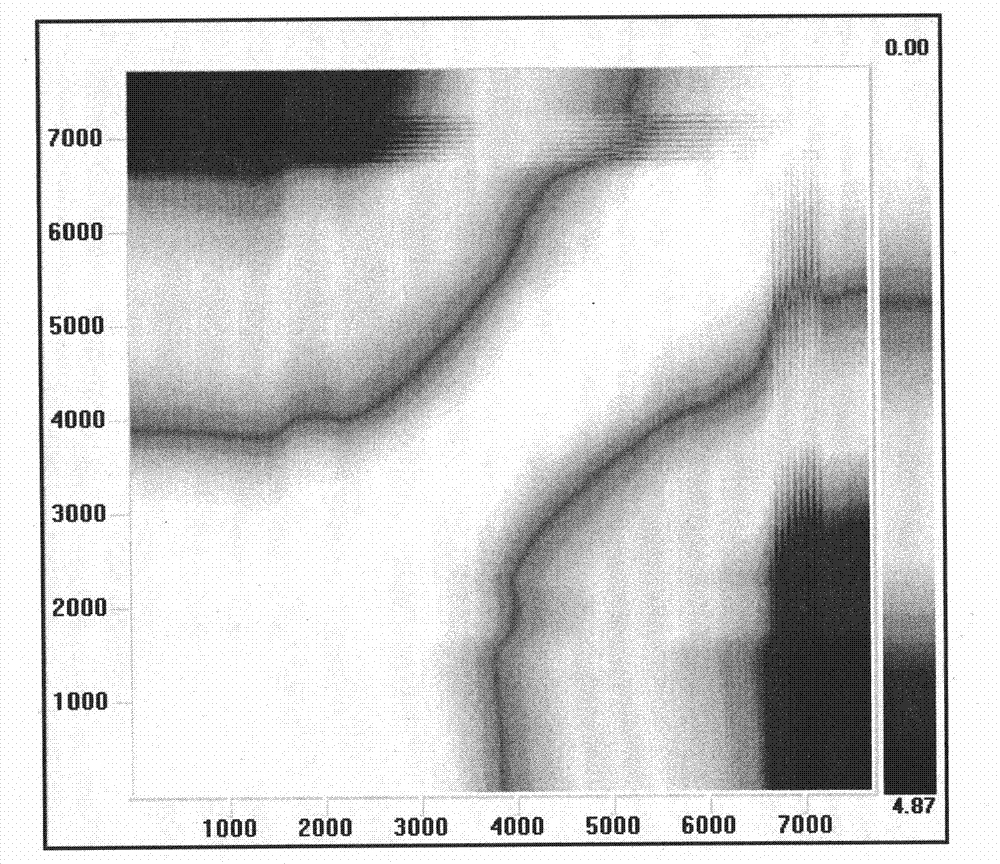

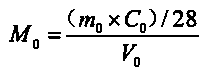

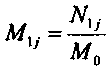

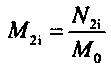

A method for dividing reaction kinetics stages in fly ash strong alkali system

The invention discloses a method for dividing reaction kinetics stages under a fly ash strong alkaline system. The method comprises the following steps: reacting a fly ash sample with a strong alkaline solution according to a determined solid-liquid ratio; calculating the dose concentration M0 of an apparent matter of a silicon element in a reaction system; after the reaction of the strong alkaline system is finished, detecting the concentration of the silicon element in the solution to obtain a silicon parameter series 1; using a dilute mixed acid solution to react with filter residues; after the reaction is finished, detecting the concentration of the silicon element in the mixed acid solution to obtain a silicon parameter series 2; calculating to obtain a characteristic parameter series 1 and a characteristic parameter system 2; carrying out comparative analysis on the characteristic parameter series 1 and the characteristic parameter system 2 to obtain a characteristic reaction boundary 2 and a characteristic reaction boundary 1; and analyzing the characteristic reaction boundary 2 and the characteristic reaction boundary 1 to obtain all the kinetics reaction stages under the fly ash strong alkaline system. The method disclosed by the invention is accurate and easy to operate, and provides a theoretical basis for comprehensive utilization of fly ash.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com