Ag-TiO2/Ti(NO2)/ITO photoelectrode, photoelectric synergistic catalytic reaction apparatus and application of photoelectric synergistic catalytic reaction apparatus

A technology of reaction device and synergistic catalysis, applied in application, chemical instruments and methods, food preservation, etc., to achieve the effect of improving photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

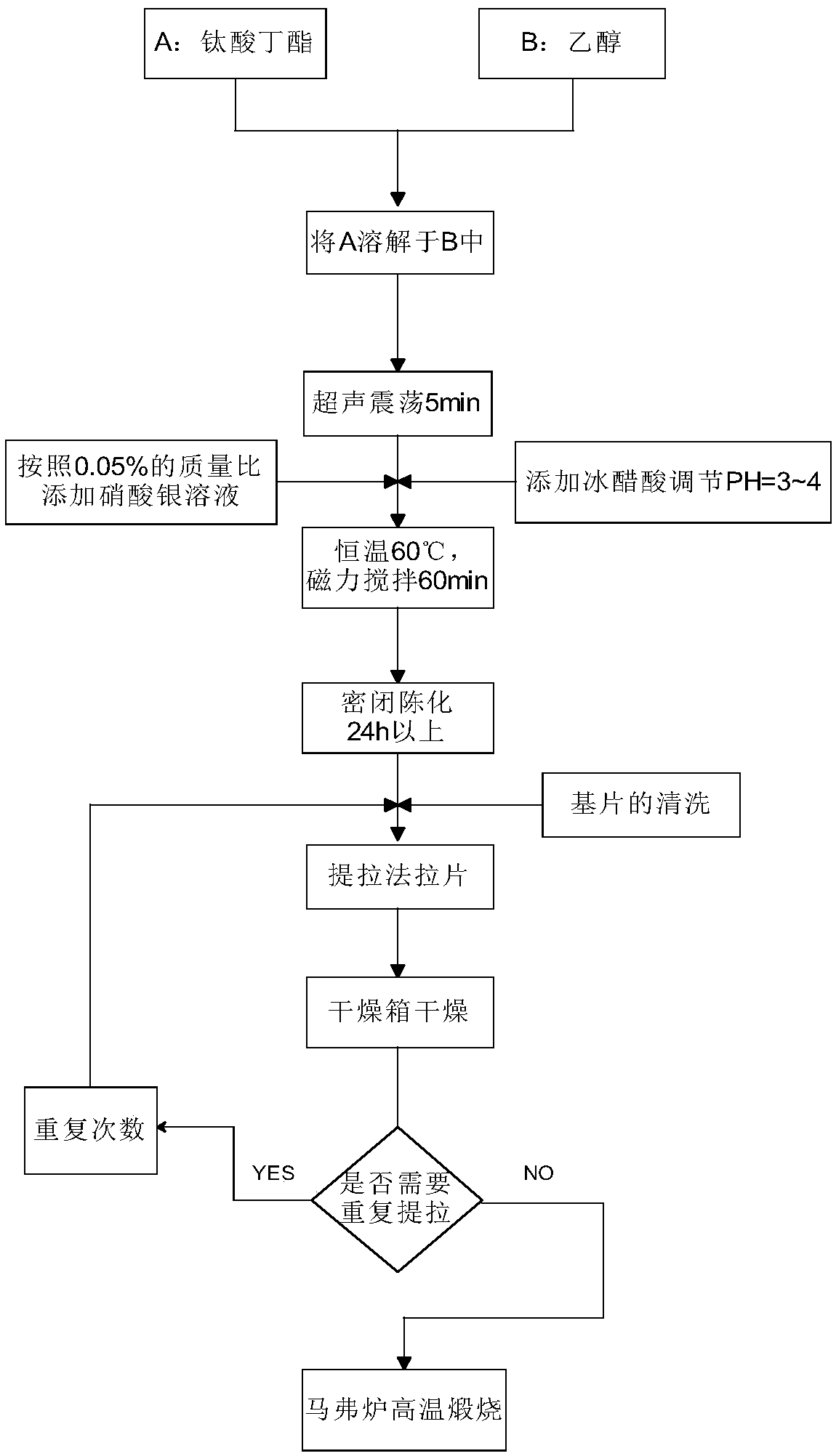

[0059] Example 1: Ag-TiO 2 / Preparation of ITO precursor film material

[0060] (1) Butyl titanate (Ti(OBu) 4 , C.P.) and ethanol (C 2 h 5 OH, A.R.) were mixed at a volume ratio of 1:5, and ultrasonically oscillated for 5 minutes with an ultrasonic cleaner.

[0061] (2) Add silver nitrate solution to the solution in step (1) so that the mass fraction of silver ions in the mixed solution is 0.05%.

[0062] (3) Add glacial acetic acid solution dropwise to adjust the pH value to about 3-4, and then continue ultrasonic oscillation for 5 minutes.

[0063] (4) Stir with a magnetic stirrer (heating at a constant temperature of 60°C) for 30 minutes, and seal and age at room temperature for more than 24 hours to obtain a stable, uniform, clear and translucent yellow-orange sol.

[0064] (5) Using clean ITO glass as the substrate, silver-doped TiO was prepared from the sol precursor by dipping and pulling method 2 The film is pulled at a relatively constant speed (2mm / s), and the ...

Embodiment 2

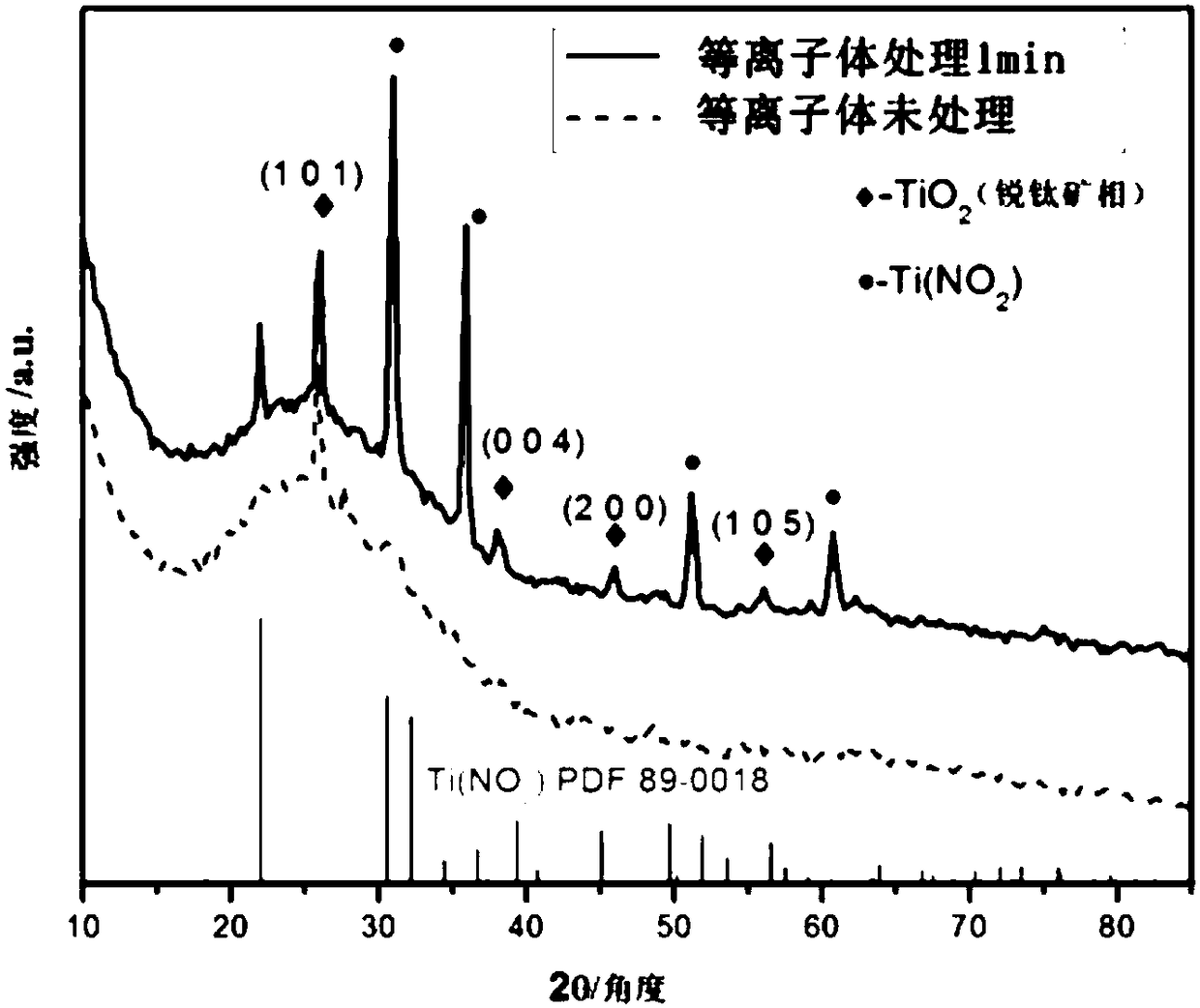

[0072] Example 2: Ag-TiO 2 / Ti(NO 2 ) / ITO material preparation

[0073] The plasma surface treatment instrument used in the low-temperature plasma test is the GM-2000 low-temperature plasma surface treatment instrument of Shenzhen Fangrui Technology Co., Ltd. The air source pressure of the plasma surface treatment instrument is 0.2~0.25MPa, the current is about 3~4A during normal operation, the treatment width is 7~13mm, and the operating temperature range is -10℃~50℃.

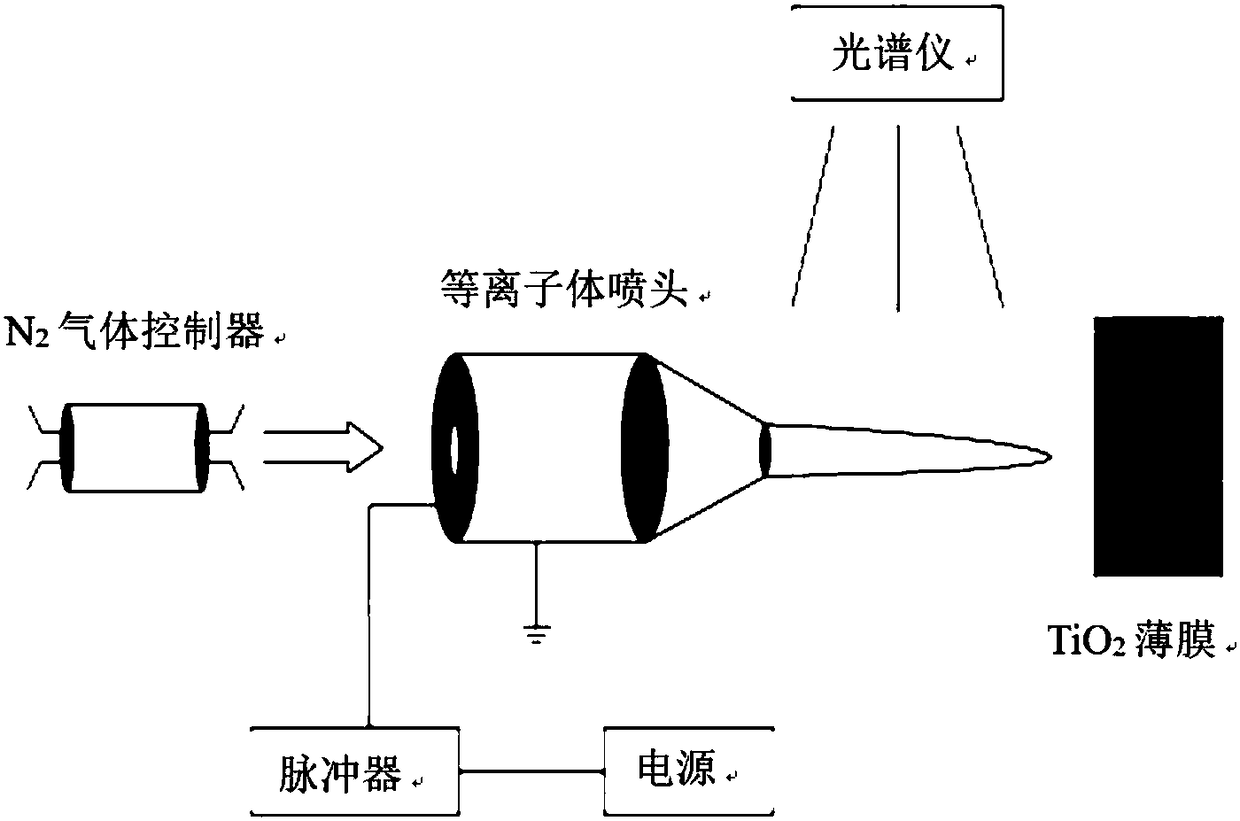

[0074] Ag-TiO 2 / Schematic diagram of ITO surface treatment process by low temperature plasma figure 2 As shown, the specific test steps are:

[0075] (1) Firstly, place the low-temperature plasma processor in a suitable position so that it is convenient to hold the nozzle with both hands, and prevent the high-voltage cables and gas pipes on the nozzle from being pulled and rubbed by force, and connect the ground wire.

[0076] (2) Different batches of Ag-TiO that will need to be processed 2 / ITO is fix...

Embodiment 3

[0084] Example 3: Ag-TiO 2 / Ti(NO 2 ) / ITO photoelectrode preparation

[0085] Nitrogen-containing lithium phosphate (LIPON) electrolyte film (purchased by Guangzhou Institute of Materials and Energy) was placed on two pieces of Ag-TiO prepared in Example 2. 2 / Ti(NO 2 ) / ITO material (plasma surface treatment time is 1min), fixed with conductive adhesive, that is, Ag-doped TiO with positive and negative electrodes 2 Thin film / ITO system.

[0086] The ionic conductivity of nitrogen-containing lithium phosphate (LIPON) electrolyte film is 6.0*10 -7 s / cm, electronic conductivity below 10 -10 s / cm. Three-dimensional conductive adhesive tape, thickness 62um, contact resistance less than 1.2Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com