Hierarchical porous titanium-silicon molecular sieve catalyst with oxidative desulfurization function and preparation method and application thereof

A titanium-silicon molecular sieve, oxidative desulfurization technology, applied in molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as low sulfur efficiency, and achieve good effects, cheap and easy-to-obtain raw materials, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a porous titanium-silicon molecular sieve catalyst with oxidative desulfurization, characterized in that it comprises the following steps:

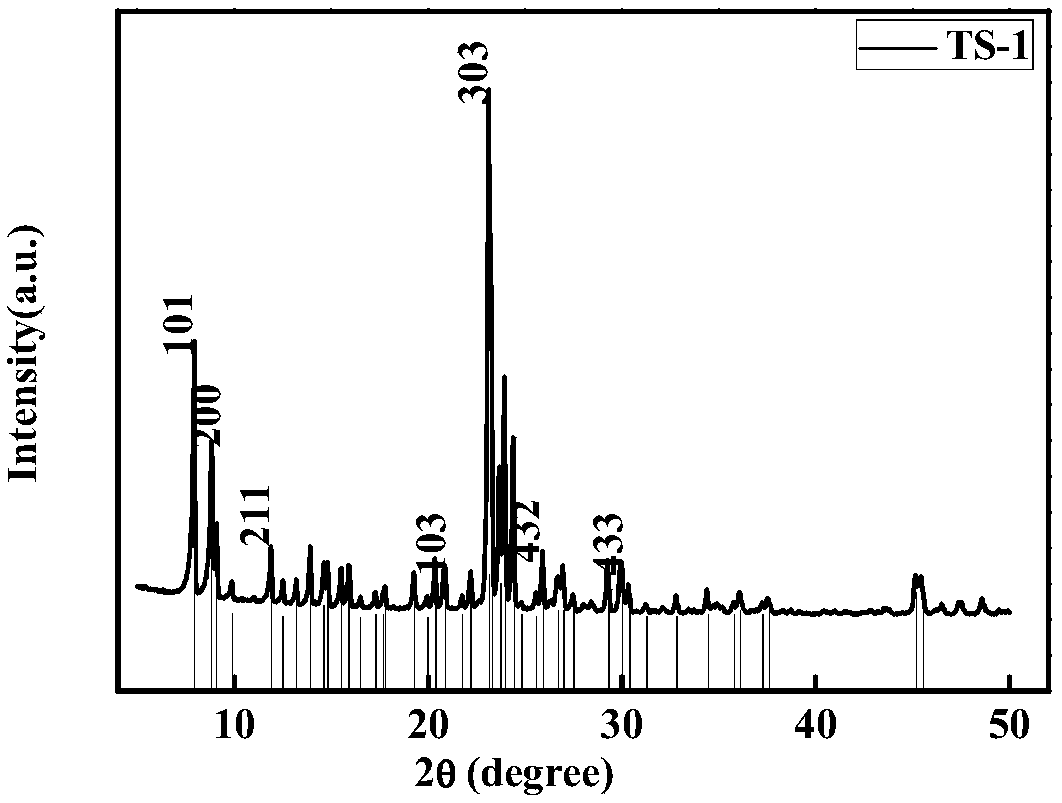

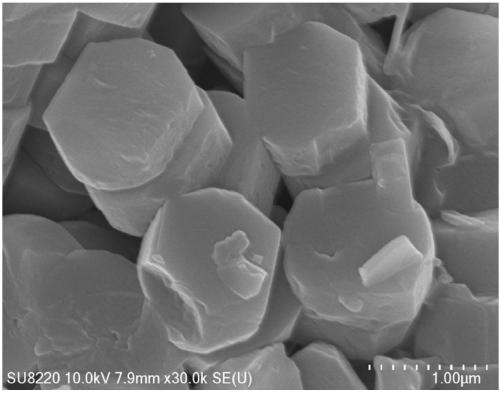

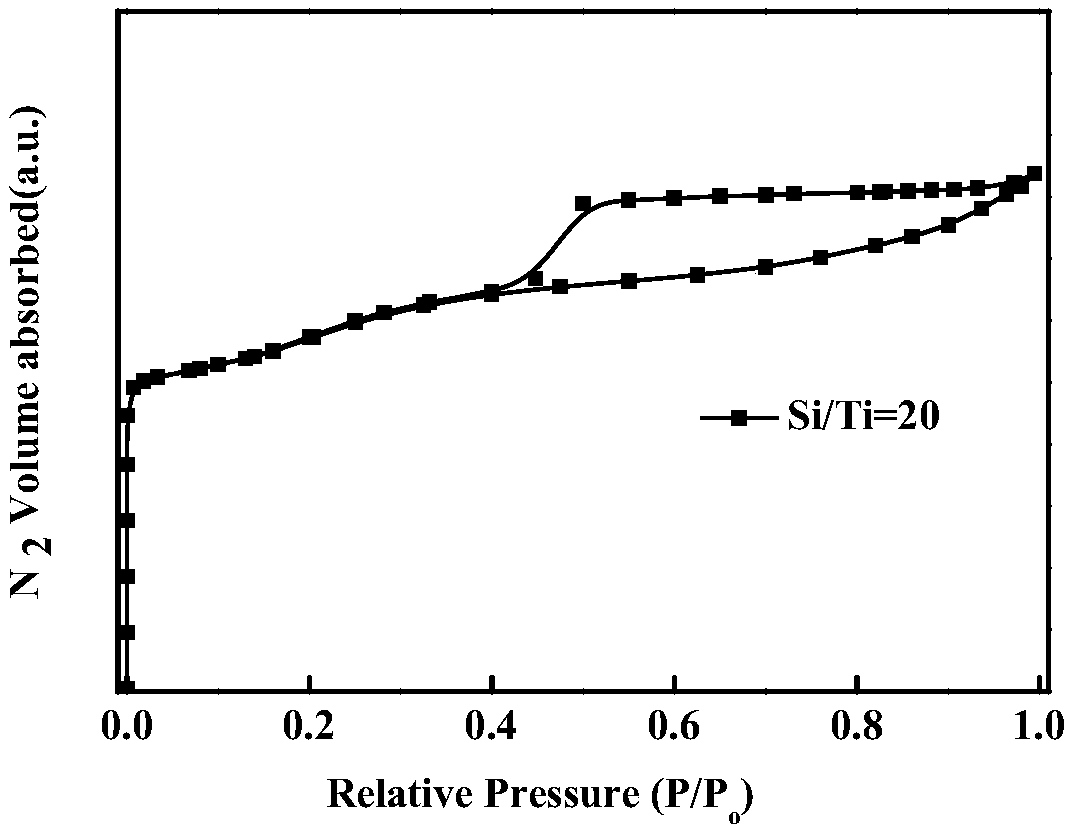

[0025] (1) Mix tetrapropylammonium hydroxide and deionized water evenly, then add ethyl silicate and butyl titanate dropwise together, and stir for 10 hours so that ethyl silicate and butyl titanate are completely decomposed; then The mixture was transferred to a 100 ml polytetrafluoroethylene-lined stainless steel autoclave, and dried in a dry box at 180 °C under static conditions for 2 days; the synthesized solid product was centrifuged at 500 rpm, and the volume Wash fully with a mixture of deionized water and ethanol at a ratio of 1:1, and then dry overnight in an oven at 80°C to obtain molecular sieve TS-1; the ethyl silicate, butyl titanate, tetrapropylammonium hydroxide and deionized The dosage of ionized water is 8.32 grams, 0.680696 grams, 8.785152 grams and 84.2751 grams respectively;

[0026] (2) ...

Embodiment 2

[0031] Embodiment 2: Carry out performance test to the TS-1 hierarchical porous molecular sieve obtained in embodiment 1

[0032] 1. Dissolve 0.2mmol (0.036852g) of dibenzothiophene in 15.0ml of acetonitrile solution, add 0.125ml (0.107g) of 1,3-diisopropylbenzene and 0.025g (25 mg) of the implementation Example 1 gained TS-1 hierarchical porous molecular sieve (mass ratio is dibenzothiophene / molecular sieve catalyst=15), then adding 2.0mmol (198.16mg) mass fraction is 35% H 2 o 2 Aqueous solution, the molar ratio is dibenzothiophene / H 2 o 2 =1 requires 30% hydrogen peroxide (226.67 mg) with a mass fraction equivalent to 204 microliters.

[0033] 2. Then start the reaction (the reaction should be at a higher dilution to prevent the crystallization of dibenzothiophene and the product, while cooling with condensed water) and heat to reflux at 60°C for 4h.

[0034] 3. Finally, take samples every half an hour and analyze them in gas chromatography (designed to take samples at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com