Method for quickly preparing silver/polypyrrole composite sol by adopting microwave method

A composite sol and polypyrrole technology, which is applied in the field of preparation of silver/polypyrrole composite sol materials, can solve problems such as slow kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

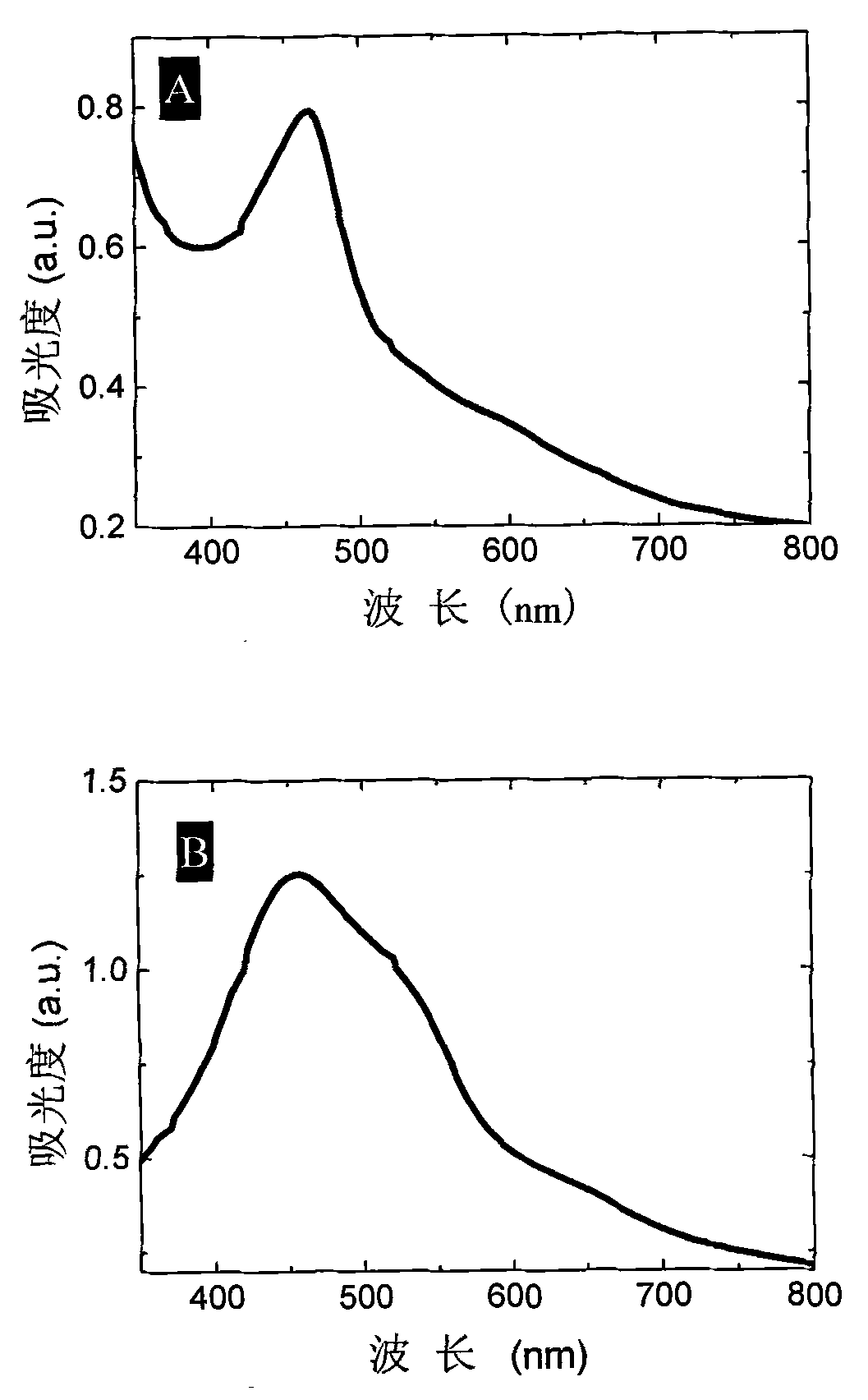

[0010] As in the above steps, weigh 300 mg of silver nitrate and 0.55 ml of pyrrole monomer, dissolve them in 40 ml of DMF respectively, and then mix the two solutions to form a mixed solution of silver nitrate + pyrrole. After stirring evenly, the mixed solution was placed in a microwave device. Under the condition of power of 500W and temperature of 70°C, Ag / PPy composite sol was obtained after microwave irradiation for 20 minutes. The UV-Vis absorption spectrum pattern is shown in figure 1 a.

Embodiment 2

[0012] As in the above steps, weigh 300 mg of silver nitrate and 0.55 ml of pyrrole monomer, dissolve them in 40 ml of DMF respectively, and then mix the two solutions to form a mixed solution of silver nitrate + pyrrole. After stirring evenly, the mixed solution was placed in a microwave device. Under the conditions of power of 600W and temperature of 70°C, Ag / PPy composite sol was obtained after microwave irradiation for 30 minutes. The UV-Vis absorption spectrum pattern is shown in figure 1 b.

Embodiment 3

[0014] As in the above steps, weigh 1.36g of silver nitrate and 5.7ml of pyrrole monomer, dissolve them in 40ml of DMF respectively, and then mix the two solutions to form a mixed solution of silver nitrate + pyrrole. After stirring evenly, the mixed solution was placed in a microwave device, and the Ag / PPy composite sol was obtained after microwave irradiation for 5 minutes at a power of 900W and a temperature of 80°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com