An energy-dissipating shear wall with limbs

A shear wall and connecting limb technology, applied in the direction of wall, building, building type, etc., can solve the problems of complex on-site construction, no structural system, uneconomical, etc. The effect of structural design freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

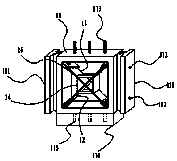

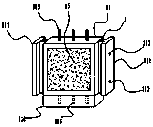

[0039] Such as Figure 5 As shown, a kind of energy dissipation shear wall with limbs is mainly composed of prefabricated shear wall panels 1, spiral double-step connecting beams 2 and steel frame connecting columns 3, such as figure 1 , 2 As shown, the prefabricated shear wall panel 1 includes a shear wall panel frame 11, a first web 12, a second web 13, a protective anti-shock component 14 and high-strength anti-shock concrete 15, and the left side of the shear wall panel frame 11 The rib and the right side rib are respectively provided with T-shaped ribs 111, and the T-shaped ribs 111 are positioned at the outer direction of the left side rib and the right side rib and are equal in length to the left side rib and the right side rib, and the vertical section of the T-shaped rib 111 There are several transverse through-holes 112 on the top, and three steel bar heads 113 are arranged on the upper edge of the shear wall panel frame 11. The steel bar heads 113 are perpendicular...

Embodiment 2

[0053] The difference with Example 1 is:

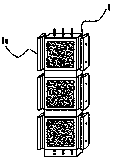

[0054] (1) if Figure 6a , 6b , 7a, and 7b, the steel frame connecting column 3 is a double T horizontal groove structure and a double T corner groove structure, which is used to connect such as Figure 12b , 12d , and 12e show two adjacent and at the same level and two adjacent and mutually perpendicular shear wall pier units 1a in the shape of a square, a concave, and a zigzag.

[0055] (2) The composition of high-strength impact-resistant concrete 15 includes by weight percentage: 27% sand and gravel, 18% cement powder, 7.5% silicon PU balls, 5.5% corundum powder, 3% explosion-proof clay, and 1.5% tempered glass beads , 0.5% binder, 0.3% dispersant, 1.5% asbestos mesh fiber, 1.5% high polyethylene fiber, 3.5% slag, 2% furnace ash, and the balance is water; among them, silicon PU balls have excellent elasticity, Added in concrete, it can make the concrete have a certain limit of self-buffering ability; the explosion-proof mortar...

Embodiment 3

[0057] The difference with Example 1 is:

[0058] (1) if Figure 6a , 6b , 6c, 7a, 7b, and 7c, the steel frame connecting column 3 is a double T horizontal groove structure, a double T corner groove structure and a triple T vertical groove structure, which are used to connect such as Figure 12c , 12f Shown are two adjacent and at the same level, two adjacent and perpendicular to each other, and three adjacent U-shaped and E-shaped shear wall pier units 1a arranged in a T-shape.

[0059] (2) The composition of high-strength impact-resistant concrete 15 includes, by weight percentage: 30% sand and gravel, 20% cement powder, 8% silicon PU balls, 6% corundum powder, 4% explosion-proof clay, and 2% tempered glass beads , 1% binder, 0.5% dispersant, 2% asbestos mesh fiber, 2% high polyethylene fiber, 4% slag, 3% furnace ash, and the balance is water; among them, silicon PU balls have excellent elasticity, Added in concrete, it can make the concrete have a certain limit of self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com