Preparation method of inner sealing phenolic foam composite air pipe with self-locking inserting strips

A technology of phenolic foam and composite air ducts, which is applied to pipes, rigid pipes, mechanical equipment, etc., and can solve problems affecting the use of air conditioners, cracking of iron sheets, aluminum foil or color steel, and peeling of inner layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages of the present invention from the content disclosed in this specification.

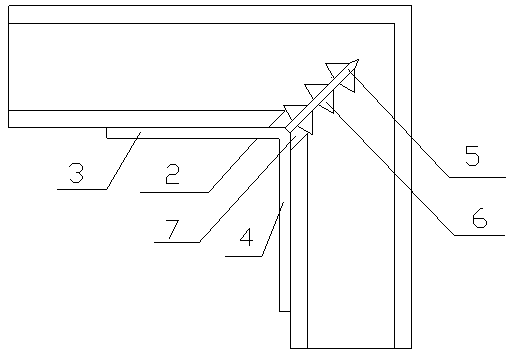

[0018] Such as figure 1 , the preparation method of the inner sealing phenolic foam composite air duct with self-locking inserts, the specific steps are as follows,

[0019] 1. Composite the phenolic foam board with the inner surface layer and the outer layer to form the main body of the air duct, and perform positioning and cutting treatment on the edge and crease surface of the air duct main body after the composite is completed, and form a gap 7 at the crease of the inner surface layer;

[0020] , Bending and splicing the main body of the air duct;

[0021] , Insert the slotting device 2 at the gap 7 on the inner surface of the air duct main body, the slotting device 2 is composed of the first welt 3, the second welt 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com