Multistage energy-saving large-impulse multifuel-combustion combustor

A burner and impulse technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of increasing production line equipment investment and operating costs, physical heat and chemical heat waste, etc., to achieve convenient operation and management, reduce Effects of equipment investment, land occupation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific drawings and embodiments.

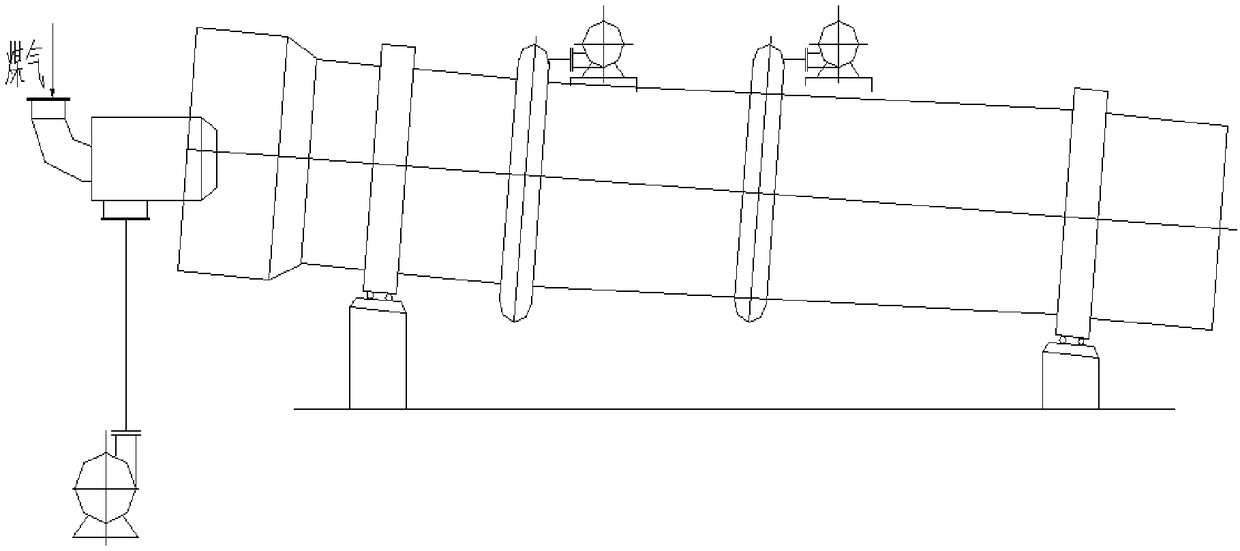

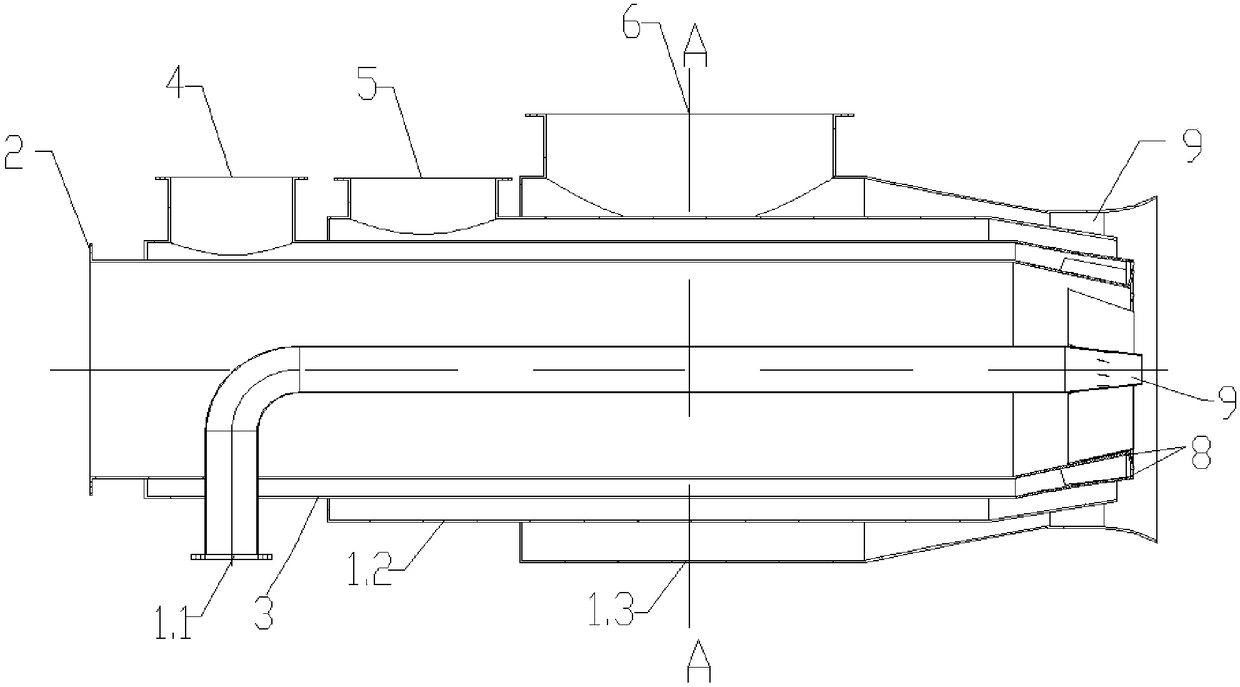

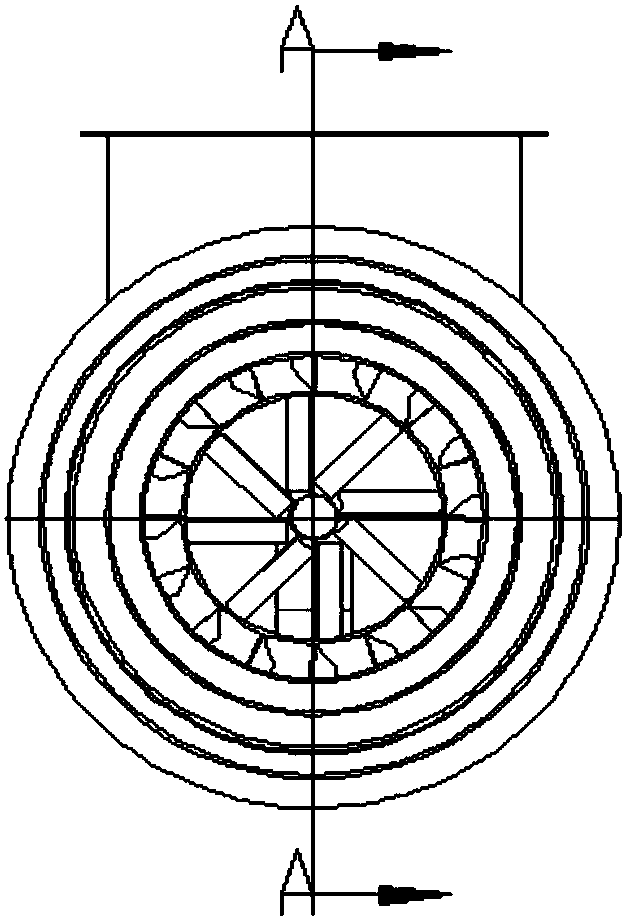

[0033] Such as Figure 1-5 Shown: a multi-stage energy-saving high-impact mixed combustion burner, characterized in that the burner includes a combustion shell 1, a tubular gas pipe 2 arranged on the combustion shell, a primary air duct 3, and a secondary air duct 4. Tertiary air pipe 5, flue gas pipe 6 and swirl blade 7;

[0034] Combustion air is divided into multiple stages to mix and burn. By setting three air ducts, the amount of each stage can be adjusted to obtain the best flame length and temperature. To ensure the rotary furnace temperature requirements.

[0035] The combustion casing 1 includes a first casing 1.1, a second casing 1.2 and a third casing 1.3;

[0036] Both the first shell and the second shell are hollow cylindrical structures; and the outer diameter of the cylinder of the second shell is larger than the outer diameter of the first sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com