Microstructure design method for capacitive pressure sensor with microstructure dielectric layer

A capacitive sensor and pressure sensor technology, applied in CAD circuit design, instrument, calculation, etc., can solve the problems that the deformation response is difficult to meet the accuracy requirements, the capacitive response curve is not presented, and the capacitive function is not calculated, etc., and the design process is convenient and fast. The design method is easy to master and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

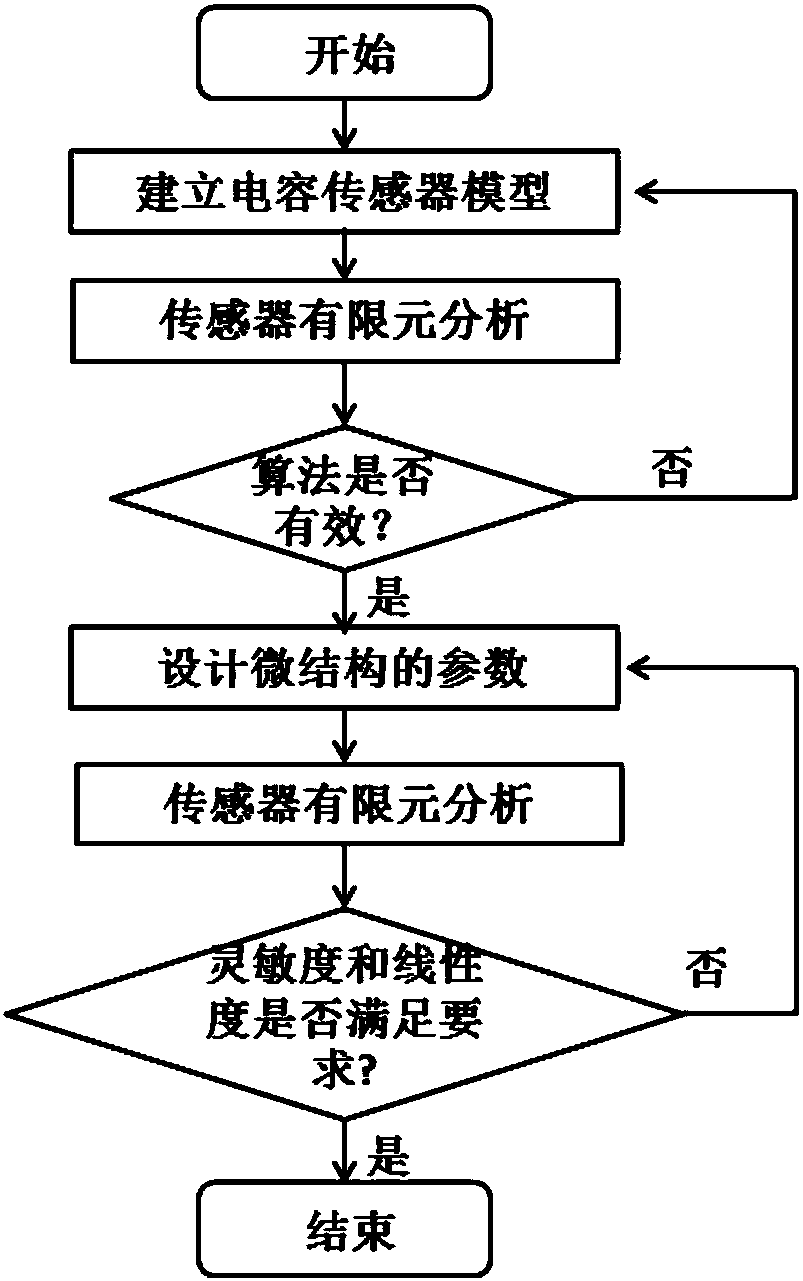

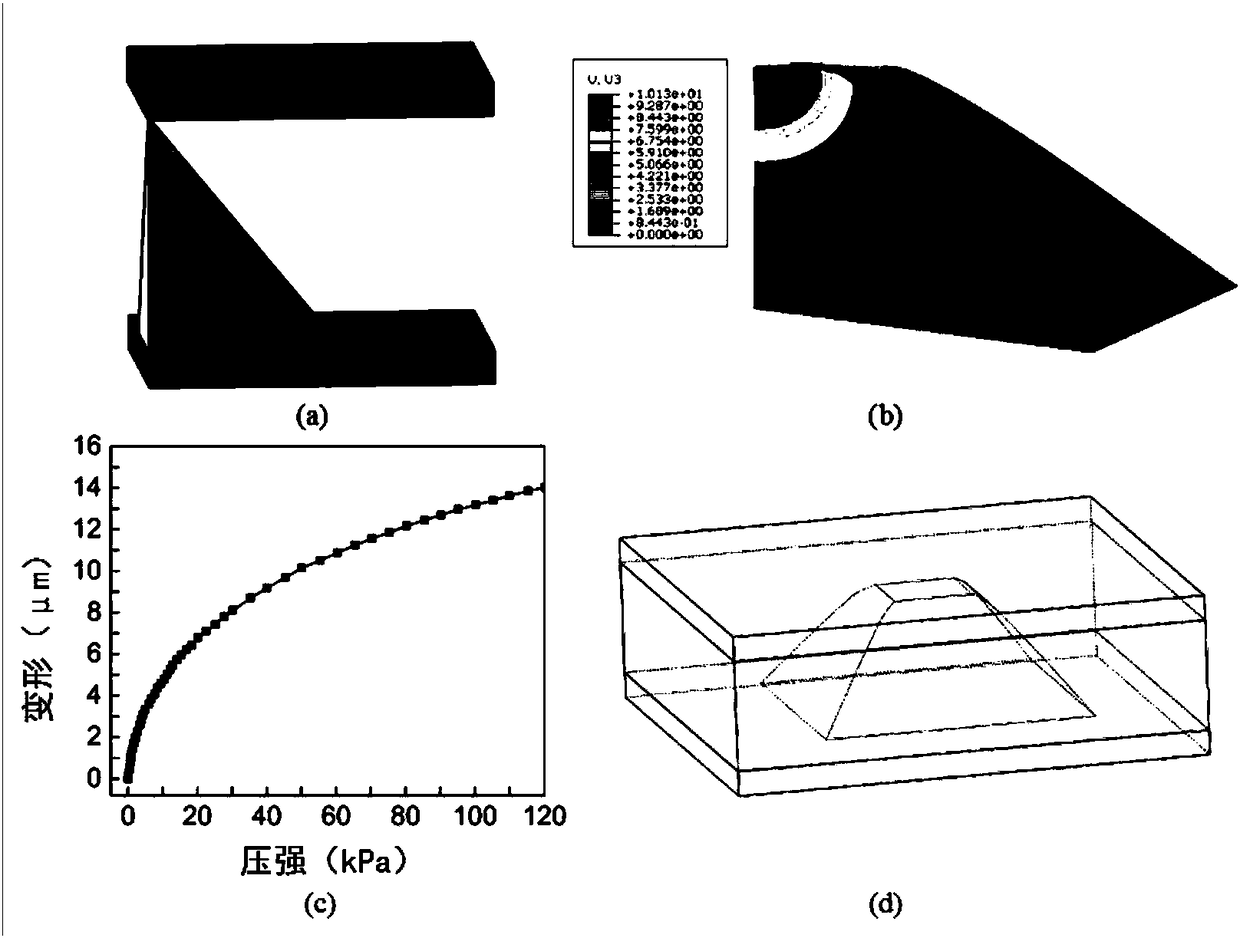

[0041] (1) First, a pyramid microstructure capacitive sensor model is established in ABAQUS to simulate the deformation response of the capacitor under pressure. Extract the geometric information of the model during the deformation process, build a new model with air domain, and simulate the capacitance in COMSOL.

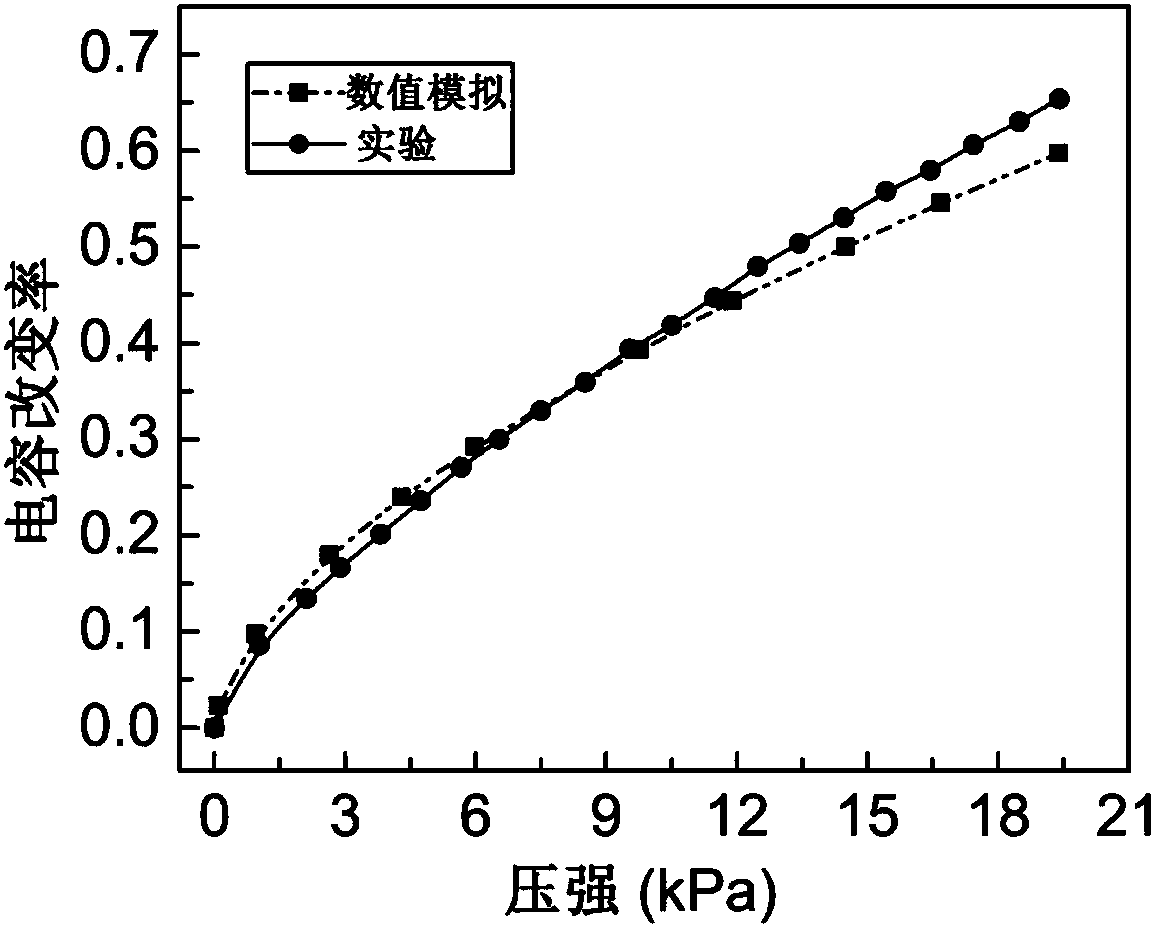

[0042] (2) The effectiveness of the algorithm is verified by comparing the simulated capacitance relative change curve with the experimental curve.

[0043] (3) Establish a capacitive sensor model, and set the material properties, shape and size of the pyramid microstructure. The design of material properties is realized by changing the elastic modulus E of the pyramid material PDMS; the pyramid shape design is realized by changing the base length L of the pyramid, the angle θ between the slope and the bottom surface and the height H of the pyramid; the pyramid size design is achieved by changing the overall Size to achieve, characterized by height h. The width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com