Scraper conveyor heavy-load adaptive start control device and start control method

An adaptive controller and self-adaptive technology, applied in the direction of conveyor control device, control electromechanical transmission device, motor control, etc., can solve the problem of mechanical structure damage such as scraper chain, uneven motor output, unbalanced power distribution, etc. problems, to achieve the effect of optimizing the startup process, reducing broken links, and improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

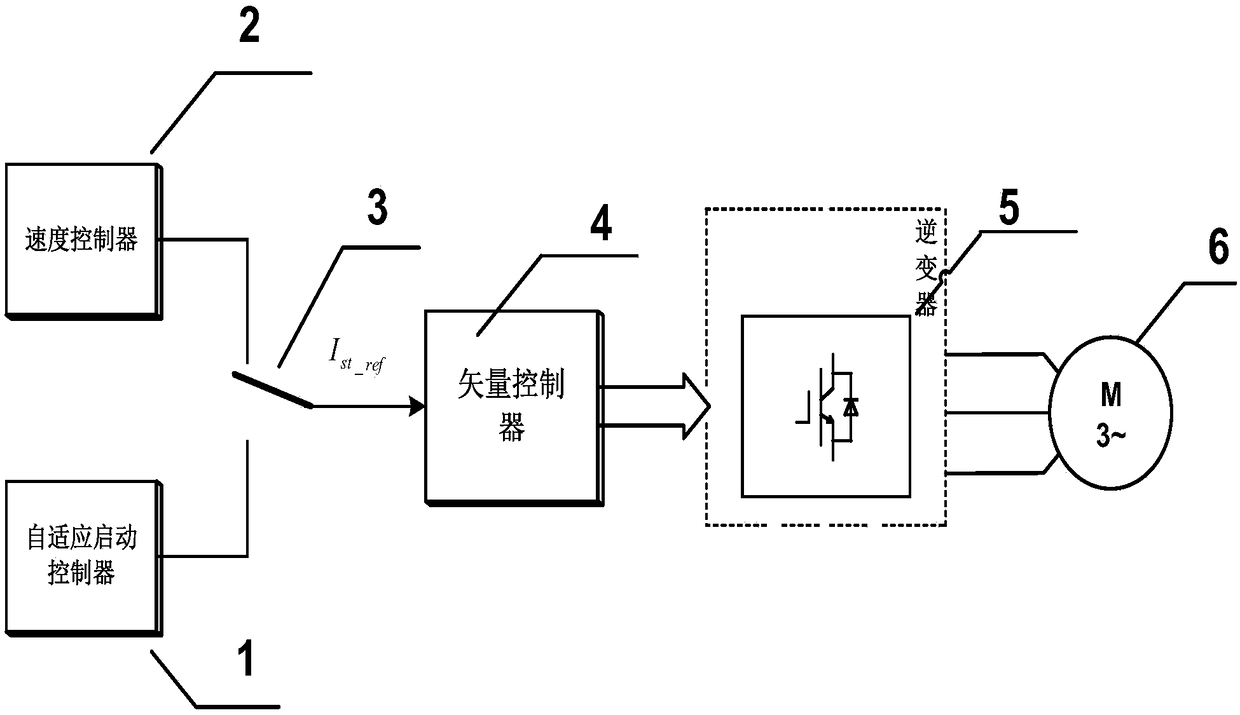

[0032] Embodiment 1: see figure 1 , image 3, a frequency converter control device for an adaptive starting controller of a scraper machine, the control device includes an adaptive controller 1, a speed controller 2, a digital switching switch 3, a vector controller 4, an inverter 5, and a motor 6. The adaptive controller 1 and the speed controller 2 are connected to the vector controller 4 through the digital switching switch 3, and the vector controller 4 is connected to the motor 6 through the inverter 5; the adaptive control The controller 1 is used to control the given torque of the vector controller 4. The speed controller 2 is used to adjust the speed feedback to track the speed given value. It receives the speed given and the speed feedback, and after the operation of the PI regulator, The output torque given value is given as the torque current given by the vector controller 4, and the digital switching switch 3 is used to select the torque and current given value of...

Embodiment 2

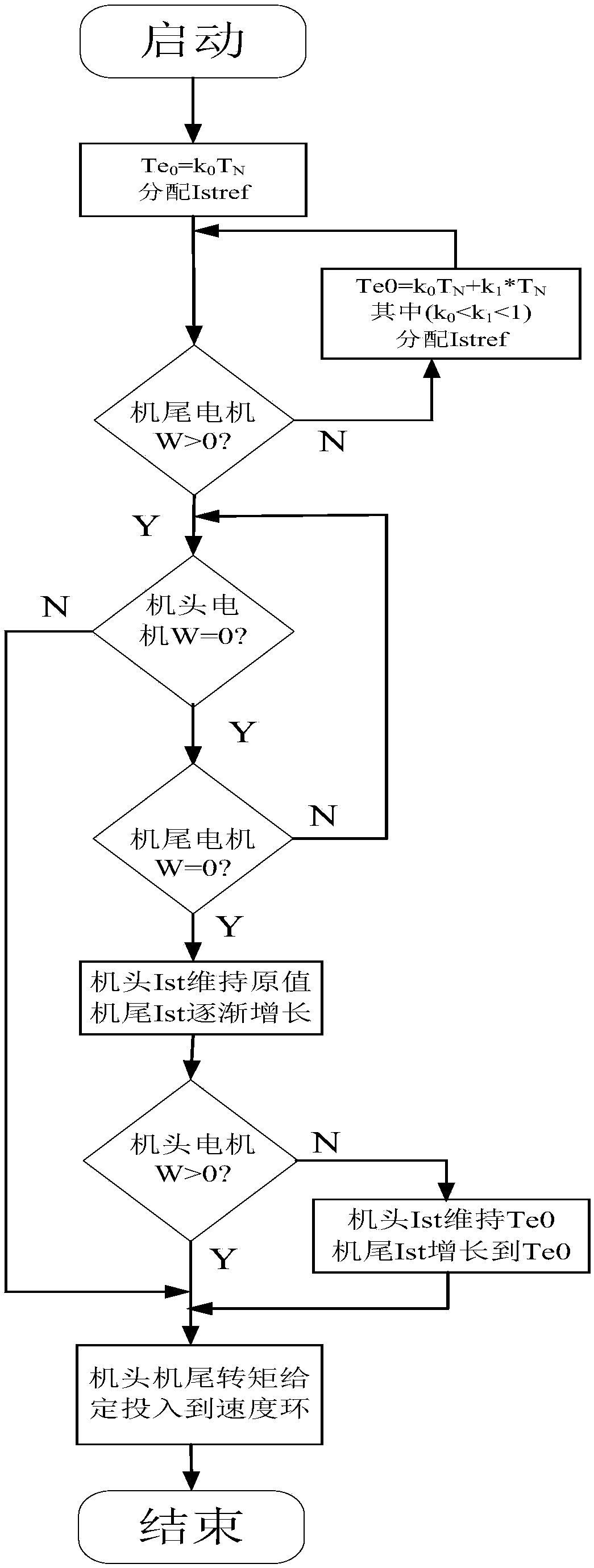

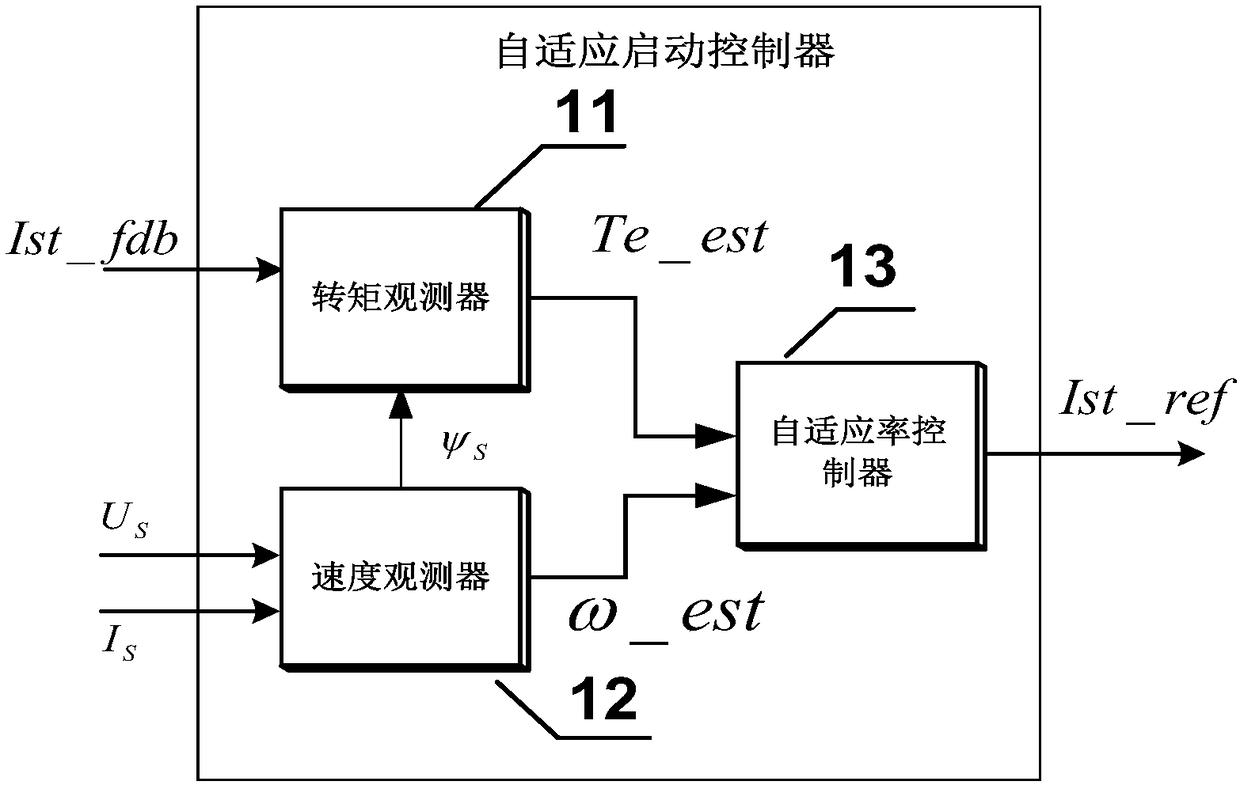

[0033] Example 2: see Figure 1-Figure 4 , a heavy-duty adaptive start-up control method for a scraper machine, comprising an adaptive start-up controller, the adaptive start-up controller including a torque observer, a speed observer and an adaptive rate controller, the torque observer Receive the torque feedback Ist_fdb output by the inverter vector control unit, and the flux linkage amplitude ψ s The real-time output torque Te_est is calculated by the torque formula, and the speed observer receives the output voltage and current Us, Is of the frequency conversion system, and through the MRAS sensorless speed estimator, calculates the real-time speed value ω_est of the motor, and the adaptive rate control By analyzing the real-time torque Te_est and real-time speed ω_est, combined with the starting strategy, the controller obtains the corresponding torque current given value Ist_ref, which is distributed to the vector control unit; the specific control steps are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com