Face cream production system

A production system, cream technology, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems of large skin damage, uneven products, irregular operation, etc., to reduce the size of particles, improve the comfort of application, improve The effect of production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

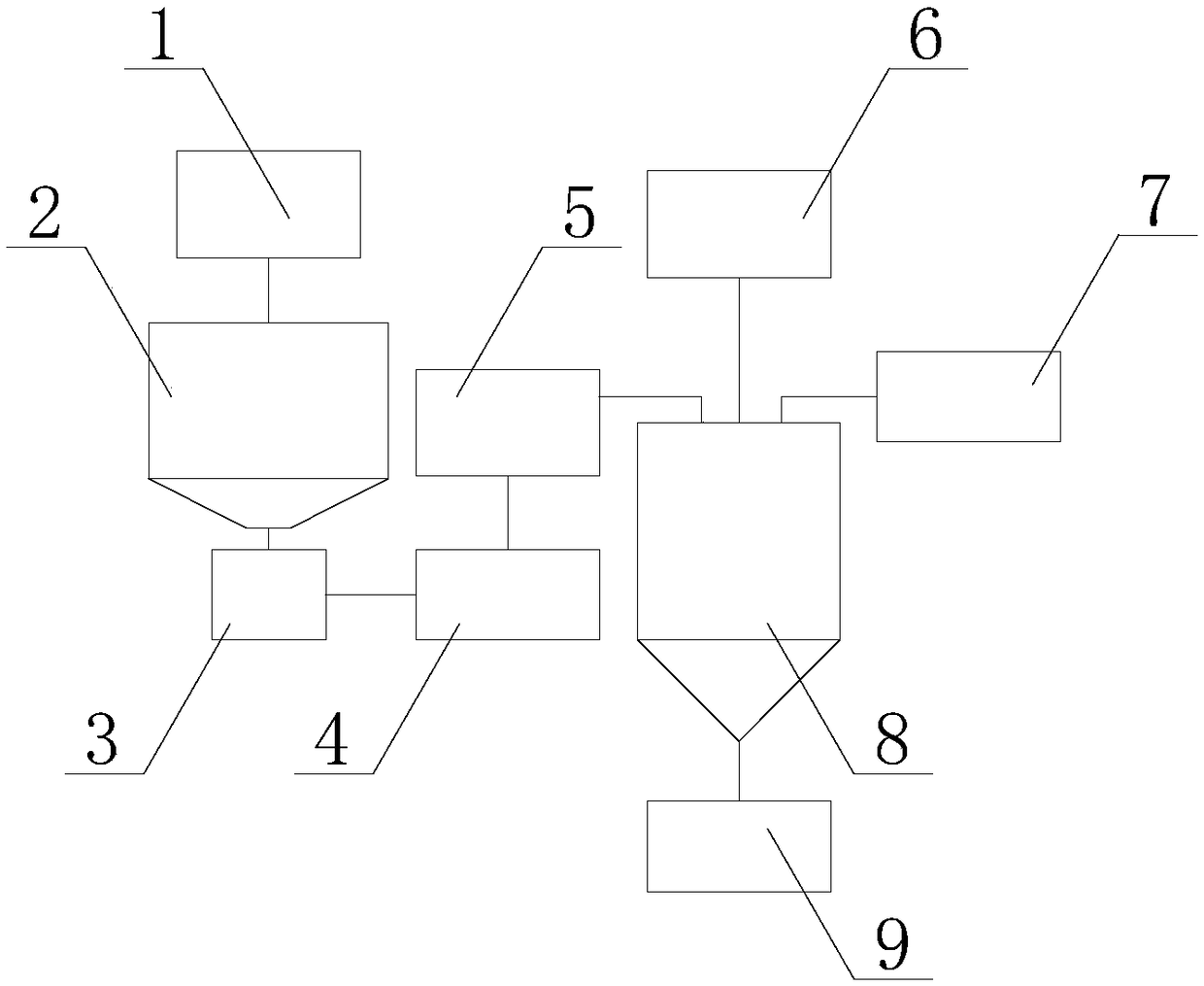

[0016] Embodiment 1: see figure 1 , a facial cream production system, mainly including high-speed pulverizer 1, stirring and separating equipment 2, multi-stage filtering device 3, dehydration device 4, fine grinding equipment 5, water phase processing equipment 6, oil phase processing equipment 7, three-phase mixing and stirring Equipment 8, the high-speed pulverizer 1, stirring and separating equipment 2, multi-stage filtering device 3, dehydration device 4, and fine grinding equipment 5 are connected in sequence through connecting pipes, and the fine grinding equipment 5, water phase processing equipment 6, oil phase The processing equipment 7 is respectively connected with the three-phase mixing and stirring equipment 8 through connecting pipes, and the production scale, specification and production volume of the face cream are greatly improved through the implementation and application of the mechanized production line.

[0017] It also includes static aging equipment 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com