Full cycle recycling method of urban construction waste and the prepared machine-made sand, concrete and blocks thereof

A technology of concrete blocks and construction waste, which is applied in the field of building materials, can solve problems such as pollution, large consumption of land expropriation fees, construction funds for garbage removal and transportation, and dust flying environment, so as to solve the shortage of sand, increase social wealth, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

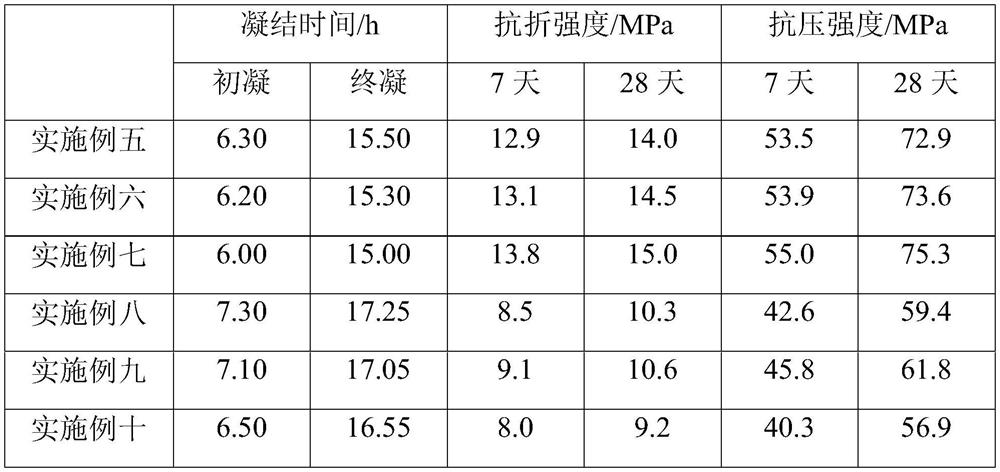

[0033] In addition, the applicant applies the building material provided by the present invention to concrete; specifically, the raw material components of the concrete include: 780-860 parts by weight of building materials, 200-340 parts by weight of cement, 1060-1100 parts by weight of stone 70-90 parts by weight of fly ash, 60-90 parts by weight of mineral powder, 6-11 parts by weight of admixture and 90-100 parts by weight of water. Among them, the preparation method of concrete includes the following steps: S301: weighing each raw material component in proportion, and then transporting building materials, cement, fly ash, mineral powder and admixtures to a mixer for stirring; S302: mixing in the product obtained in S301 Add the remaining raw material components and continue mixing to finally get concrete.

[0034] Preferably, the raw material components of the concrete further include: 10-30 parts by weight of tourmaline powder, 5-15 parts by weight of diatomite, 3-8 part...

Embodiment 1

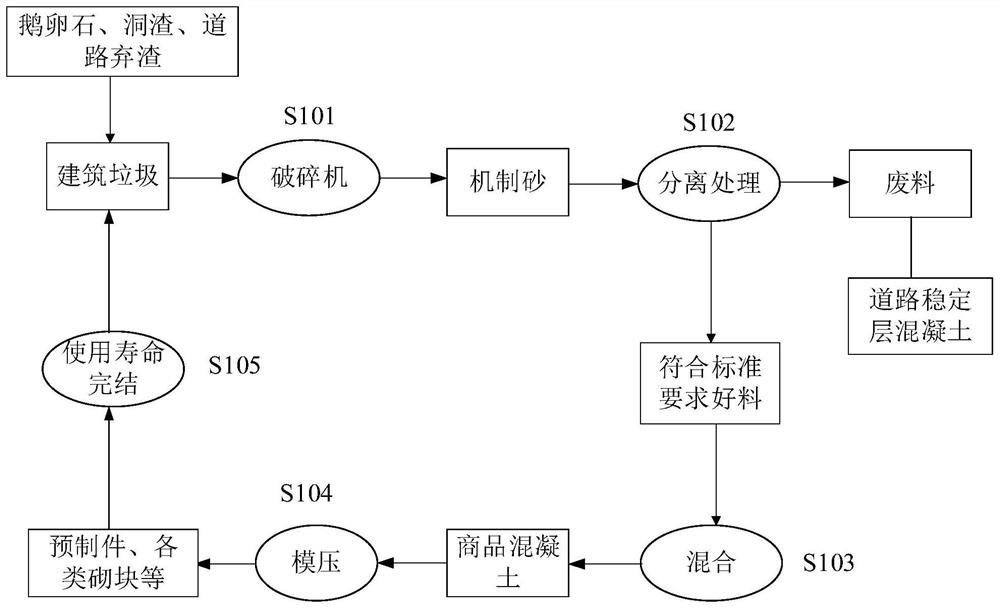

[0037] The invention provides a method for recycling construction waste, comprising the following steps:

[0038] S101: Process the construction waste with an impact crusher, specifically including: S201: Send the construction waste into a fine-toothed jaw crusher for coarse crushing, so that the particle size of the output is less than or equal to 80mm, and then remove it with a permanent magnet iron remover Iron filings in the discharged material; S202: Transport the material after removal of iron filings to the cone crusher for further crushing, and the fan blows the material continuously during the conveying process to clean out the light impurities in the material, and then crush the pellets Materials with a diameter less than or equal to 10mm are sent to the vibrating screen by the belt conveyor for screening; S203: The materials obtained in S202 are transported to the impact crusher through the bucket elevator, and then enter the mold-controlled screen through the vibrat...

Embodiment 2

[0044] The invention provides a method for recycling construction waste, comprising the following steps:

[0045] S101: Process the construction waste with an impact crusher, specifically including: S201: Send the construction waste into a fine-toothed jaw crusher for coarse crushing, so that the particle size of the output is less than or equal to 80mm, and then remove it with a permanent magnet iron remover Iron filings in the discharged material; S202: Transport the material after removal of iron filings to the cone crusher for further crushing, and the fan blows the material continuously during the conveying process to clean out the light impurities in the material, and then crush the pellets Materials with a diameter less than or equal to 10mm are sent to the vibrating screen by the belt conveyor for screening; S203: The materials obtained in S202 are transported to the impact crusher through the bucket elevator, and then enter the mold-controlled screen through the vibrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com