Method for preparing graphene-reinforced aluminum matrix composite material by injection molding

A technology for strengthening aluminum-based and composite materials, which is applied in the field of injection molding to prepare graphene-reinforced aluminum-based composite materials, can solve the problems of long production cycle, complex molding process, and difficult to control temperature accurately, and achieve strict procedures, advanced technology, and data Accurate and detailed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing:

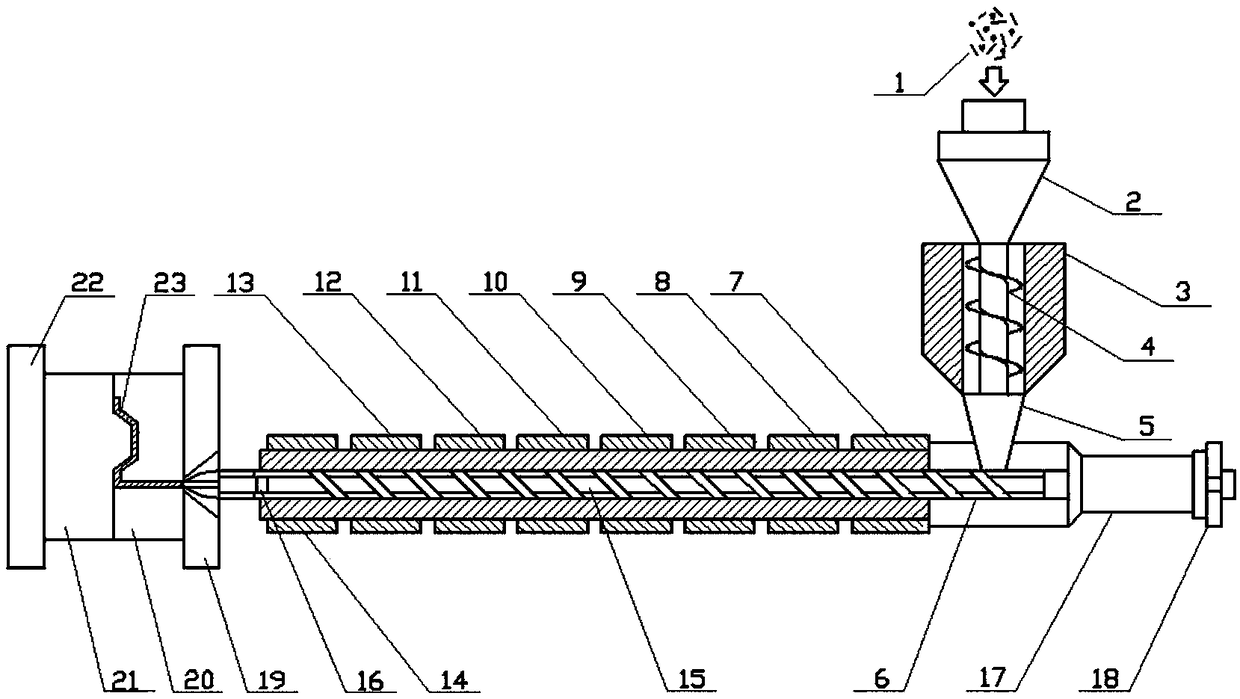

[0044] figure 1 As shown, it is the semi-solid thixotropic injection molding state diagram of the graphene-reinforced aluminum matrix composite material. The position and connection relationship of each part must be correct, and the ratio should be adjusted according to the quantity and operated in sequence.

[0045] The mixing treatment of graphene aluminum alloy semi-solid slurry is carried out in a semi-solid thixotropic injection molding device, which is completed in the process of feeding, quantitative transportation, heating, screw shearing, preparation of semi-solid slurry, and high-speed injection molding;

[0046] The mixed graphene / aluminum alloy mixed particles 1 are added to the storage hopper 2 of the device, and the storage hopper 2 is connected to the injection machine feeding hopper 3, and the hollow part of the injection machine feeding hopper 3 is the feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com