Functional test system based on minimum battery management system and test method thereof

A battery management system and functional testing technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of poor applicability, inconvenient operation, and high cost of testing equipment, and achieve low cost, small size, and simple operating system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

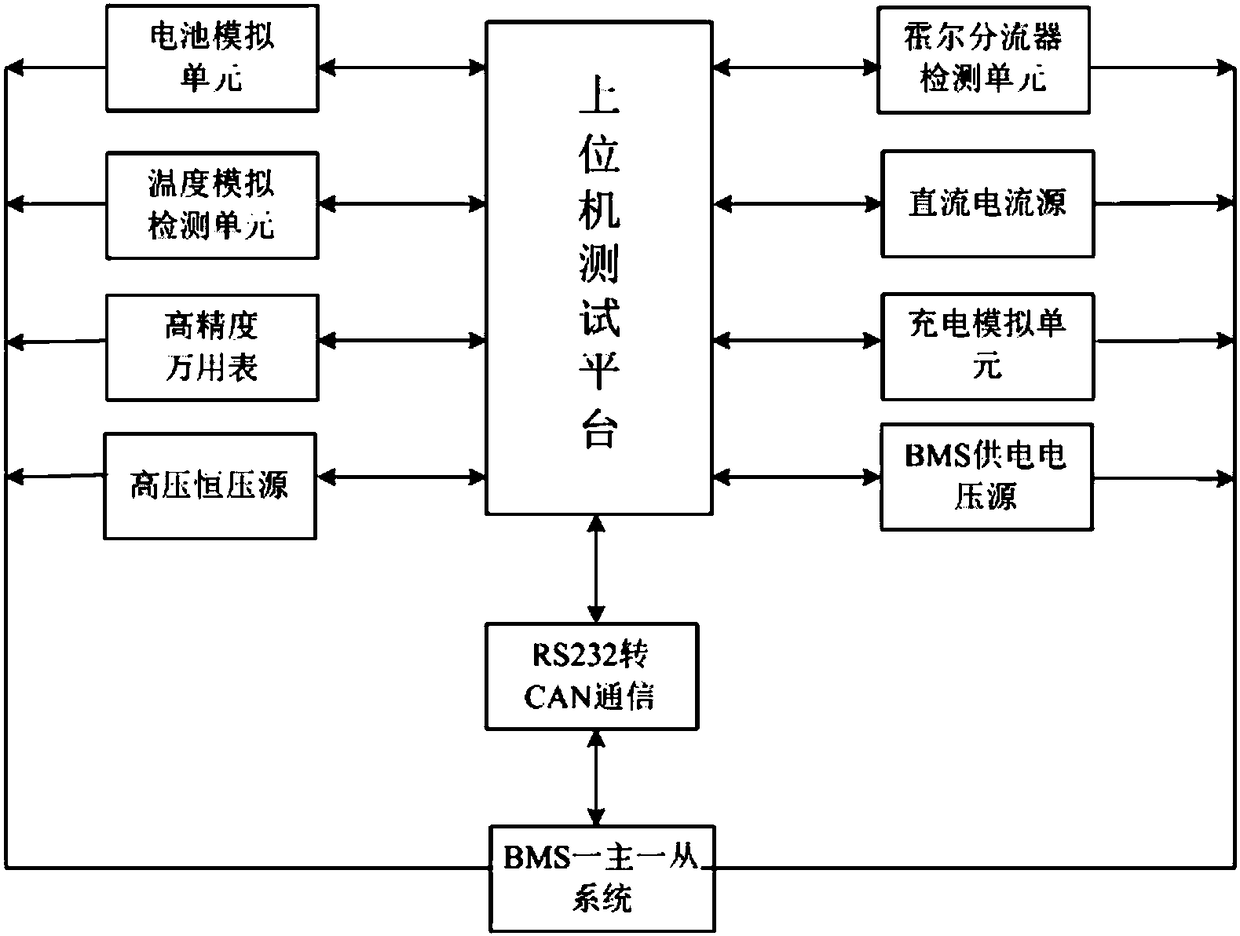

[0030] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0031] Such as figure 1 As shown, a functional test system based on the minimum battery management system of the present invention includes an upper computer test platform for parameter setting, display and simulation of at least one slave control module in the BMS battery management system and the upper computer test platform The connected BMS one-master-slave minimum system is used to provide the main control module and slave control module of the real BMS battery management system, collect the data of other modules and upload them to the host computer test platform for display;

[0032] The battery simulation unit is used to simulate the voltage signal of the single battery,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com