High-power gyrotron collecting stage

A gyrotron and high-power technology, which is applied to collectors of time-of-flight electron tubes, discharge tubes, and time-of-flight electron tubes. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

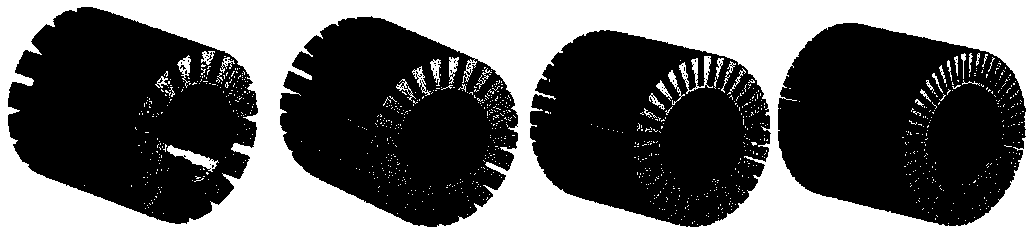

[0020] A high-power gyrotron collection stage, which includes a cylindrical inner wall and a plurality of cooling fins arranged outside the inner wall, is characterized in that each cooling fin is in a spiral structure around the outer side of the inner wall, and the gap between adjacent cooling fins The gap is a spiral coolant channel. The bottom of the spiral cooling liquid channel (that is, the outer side of the cylindrical inner wall) is a corrugated structure. Further, the collection stage includes 48 cooling fins, the cooling liquid channel is 1 mm wide, the helix angle of each cooling fin is 360 degrees, the cylindrical inner wall radius is 15 mm, the collection stage length is 50 mm, and the wall thickness is 1.5 mm. The coolant channels are 7.5mm deep.

Embodiment 2

[0022] A high-power gyrotron collection stage, which includes a cylindrical inner wall and a plurality of cooling fins arranged outside the inner wall, is characterized in that each cooling fin is in a spiral structure around the outer side of the inner wall, and the gap between adjacent cooling fins The gap is a spiral coolant channel. The bottom of the spiral cooling liquid channel (that is, the outer side of the cylindrical inner wall) is a corrugated structure. Further, the collection stage includes 36 cooling fins, the cooling liquid channel is 1.5mm wide, the helix angle of each cooling fin is 360 degrees, the cylindrical inner wall radius is 15mm, the collection stage length is 50mm, and the wall thickness is 1.5mm. The coolant channels are 7.5mm deep.

Embodiment 3

[0024] A high-power gyrotron collection stage, which includes a cylindrical inner wall and a plurality of cooling fins arranged outside the inner wall, is characterized in that each cooling fin is in a spiral structure around the outer side of the inner wall, and the gap between adjacent cooling fins The gap is a spiral coolant channel. The bottom of the spiral cooling liquid channel (that is, the outer side of the cylindrical inner wall) is a corrugated structure. Further, the collection stage includes 24 cooling fins, the cooling liquid channel is 2mm wide, the helix angle of each cooling fin is 360 degrees, the cylindrical inner wall radius is 15mm, the collection stage length is 50mm, and the wall thickness is 1.5mm. The coolant channels are 7.5mm deep.

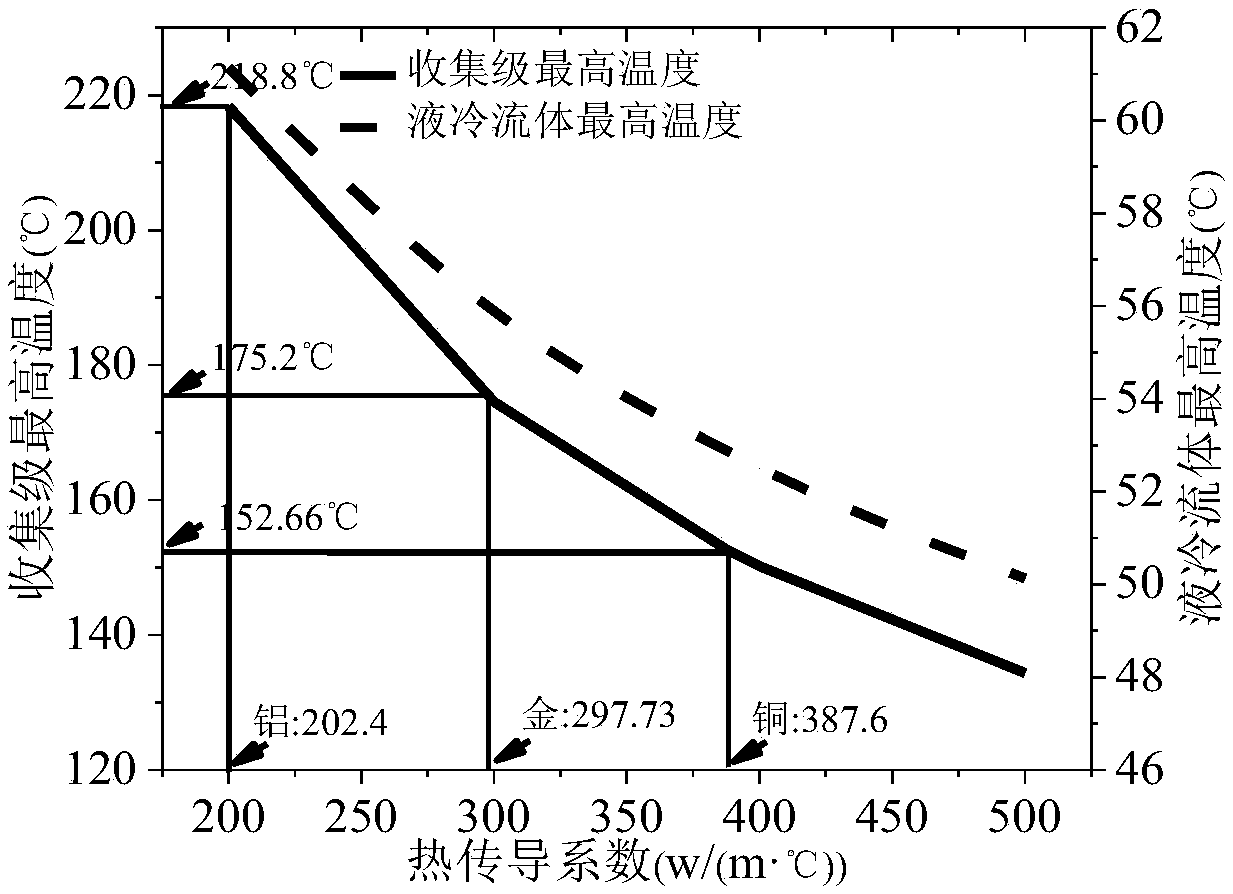

[0025] refer to figure 1 As shown in Fig. 1, increasing the thermal conductivity of the collection-level material can quickly transfer the dissipated power per unit area to the low-temperature region. When the dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com