Method for operating fuel cell system and setting relative humidity of cathode operating gas

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell control, fuel cell additives, etc., can solve the problems of not reaching the target humidity, inaccuracy, etc., and achieve the goal of avoiding the reduction of relative humidity and preventing temperature changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

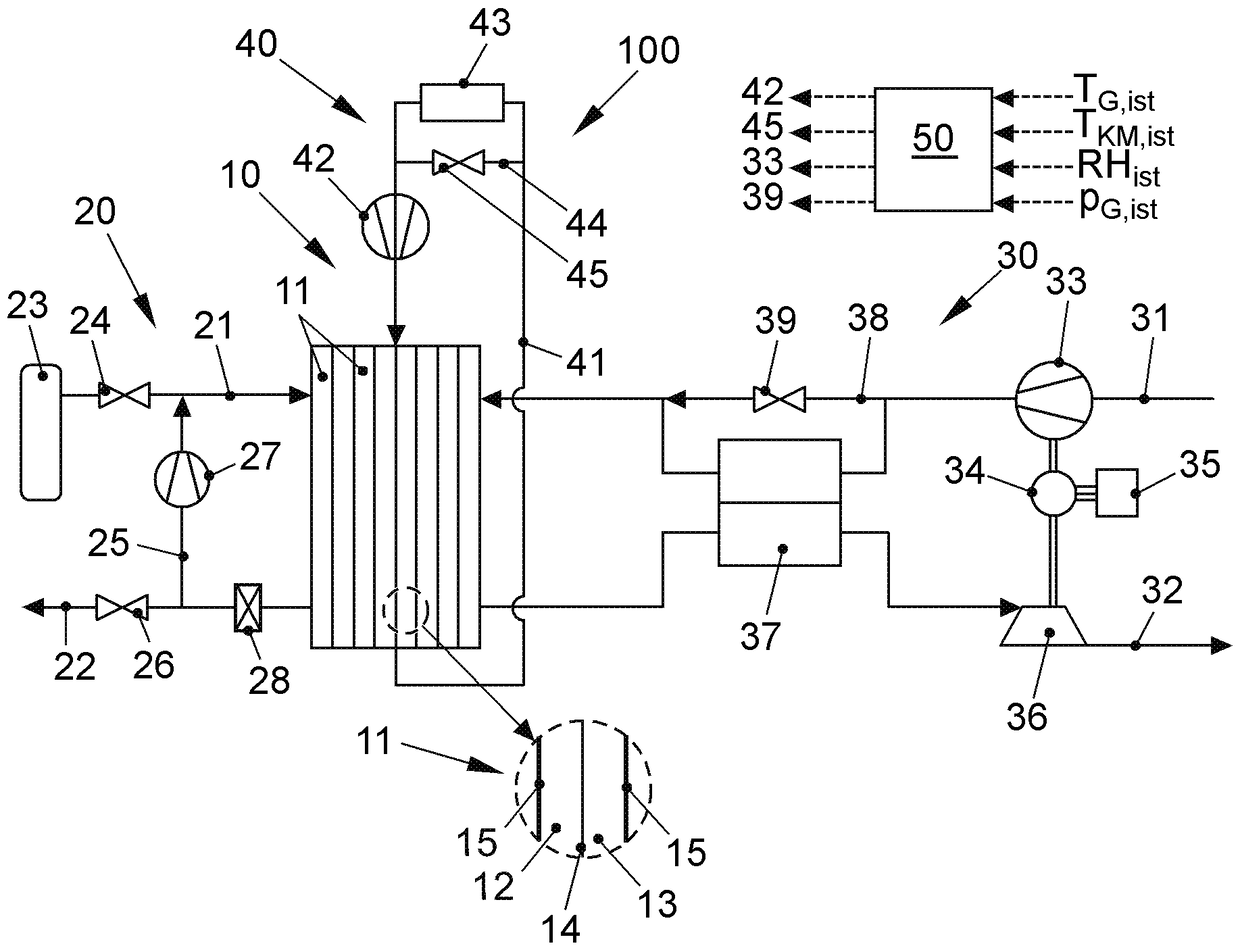

[0040] figure 1 A fuel cell system, generally designated 100 , according to a preferred embodiment of the invention is shown. The fuel cell system 100 may be part of a vehicle not shown further, in particular an electric vehicle having an electric traction motor which is supplied with electrical energy via the corresponding fuel cell system 100 .

[0041] The fuel cell system 100 comprises, as a core component, a fuel cell stack 10 having a plurality of individual cells 11 arranged in a stack shape through alternately stacked membrane-electrode-assemblies (MEAs) 14 and bipolar plates. 15 constructions (refer to snippet for details). Each individual cell 11 thus comprises an MEA 14 in each case and catalytic electrodes arranged on both sides, namely an anode and a cathode, which catalyze the respective partial reactions of the fuel cell conversion, wherein the MEAs 14 have here Ion-conducting polymer electrolyte membrane not shown further. The anode and cathode electrodes ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com