Acquisition method of coordinate of point position to be processed on arc segment workpiece surface on rotary workbench

A technology for rotating workbenches and workpiece surfaces, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., and can solve the problems of low manual marking efficiency, low efficiency, large manual marking errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

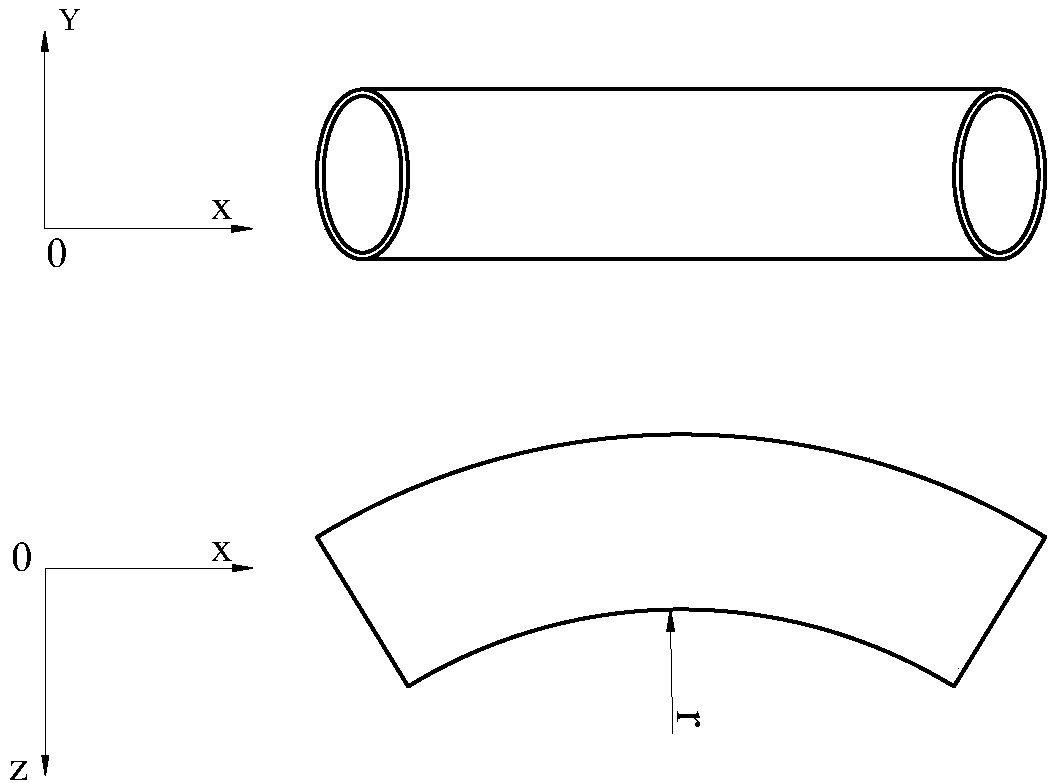

[0064] 1. will Figure 4 The arc-shaped elbow shown is in accordance with the figure 2 The method shown is placed on the rotary table of the CNC floor boring and milling machine, and the outer side of the workpiece arc faces the rotation center of the table.

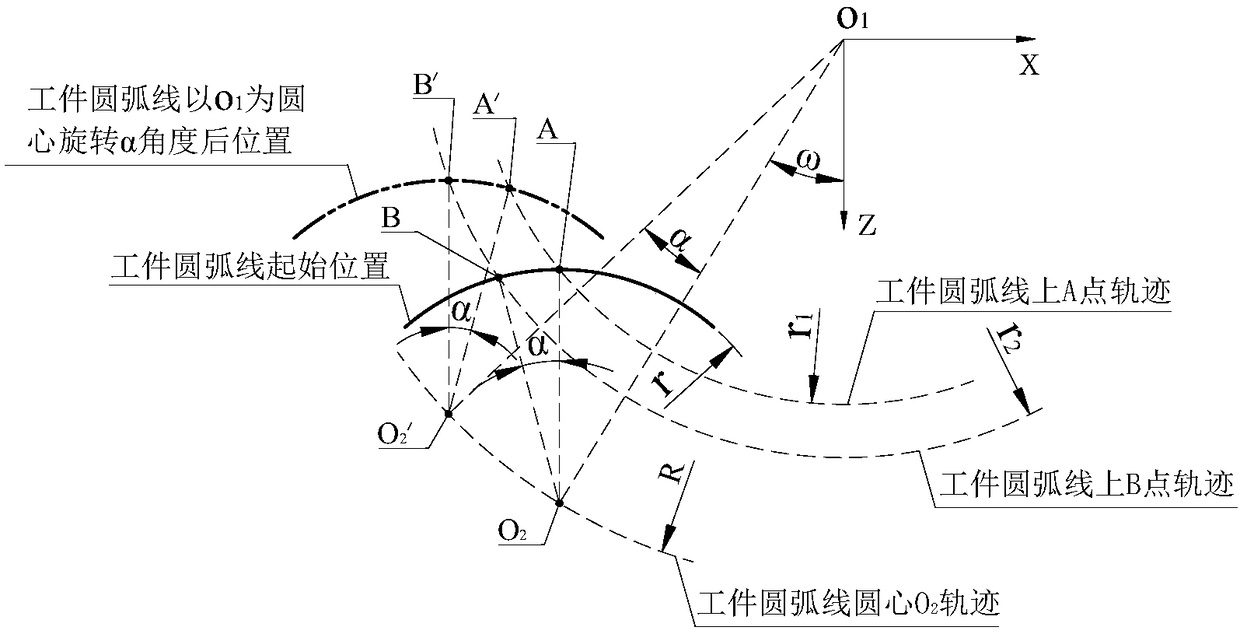

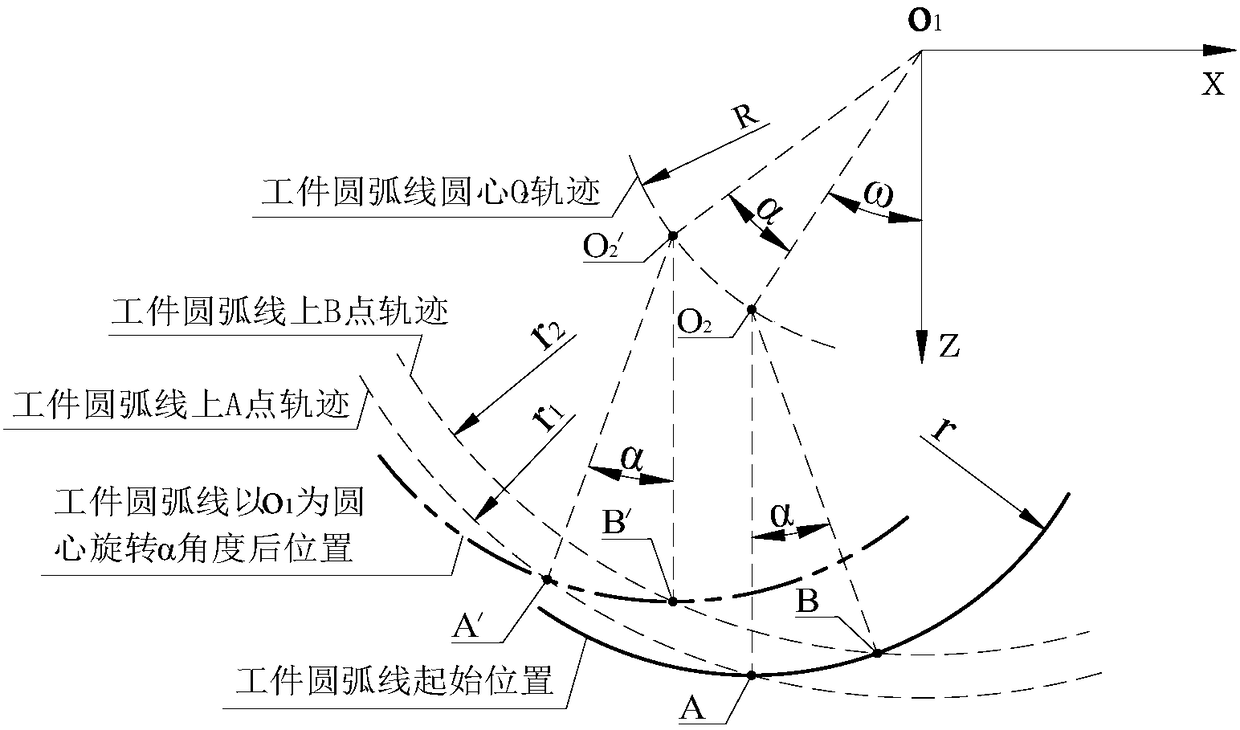

[0065] 2. There are 20 φ60 holes to be processed on the surface of the workpiece, and the radial angle between adjacent holes to be processed is 5°. Take a point to be processed on the arc line of R=1700 as the initial processing point A, and adjust the position of the workpiece , so that the radial direction of the initial processing point A on the workpiece coincides with the spindle direction of the CNC floor boring and milling machine, clamp the workpiece, and then collect the coordinate A (6154.79, -1601.9) of point A in the machine tool coordinate system, and then set it at R=1700 Randomly pick another point P on the arc line of , collect the coordinates of point P (7655.8, -700), and mark the two points A and P; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com