Method for preparing polypropylene/expanded graphite composite by water-assisted melting and mixing extrusion and application of method

A technology for melting, kneading and expanding graphite, applied in the field of polymer material/expanded graphite composite material and its preparation, can solve the problems of difficult industrialized production, long cycle, complex preparation process of composite material, etc., and achieves easy control and low production cost. , the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

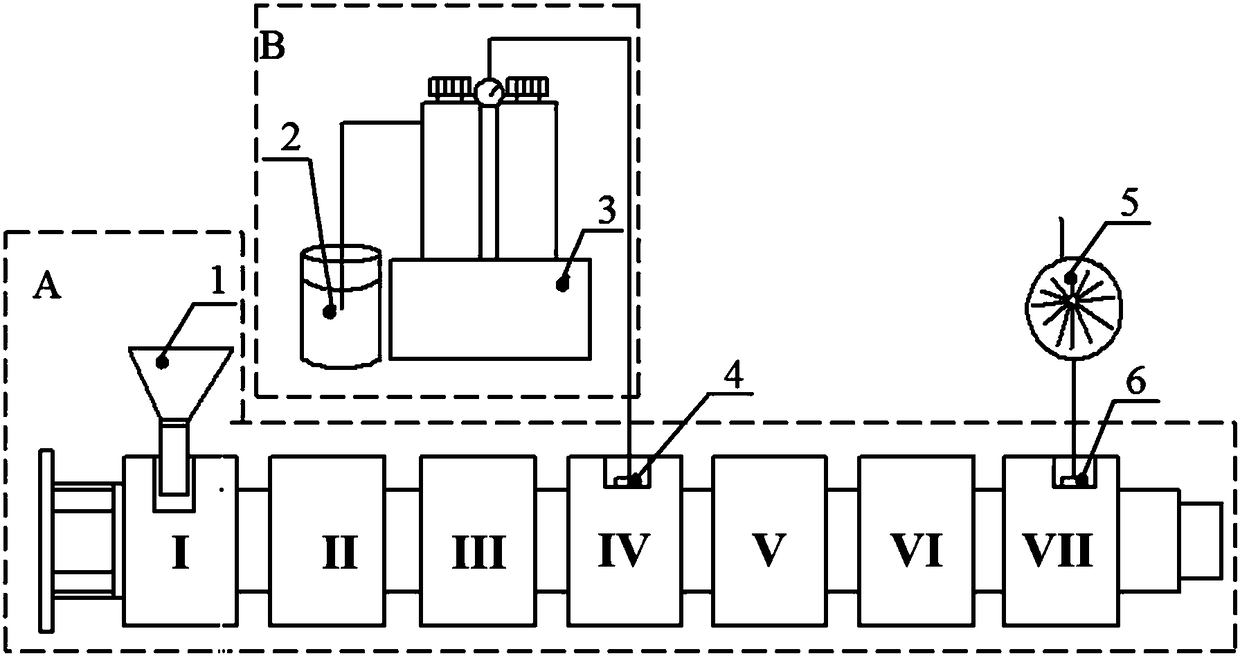

[0032] The water-assisted melting mixing extrusion equipment adopted in the present invention comprises an extruder, a set of water injection device, and a water ring vacuum pump. Along the flow direction of the material, the barrel of the extruder is provided with a feeding port, a water injection port and an exhaust port. The feeding port is used to add premixed PP, PP-g-MA and EG powder mixture, the water injection port is used to inject deionized water, and the exhaust port is used to extract water vapor. The water injection port is provided with a nozzle, and the nozzle is connected with a water injection device, and the water injection device includes a liquid storage cylinder and a metering pump. The exhaust port is connected with a water ring vacuum pump.

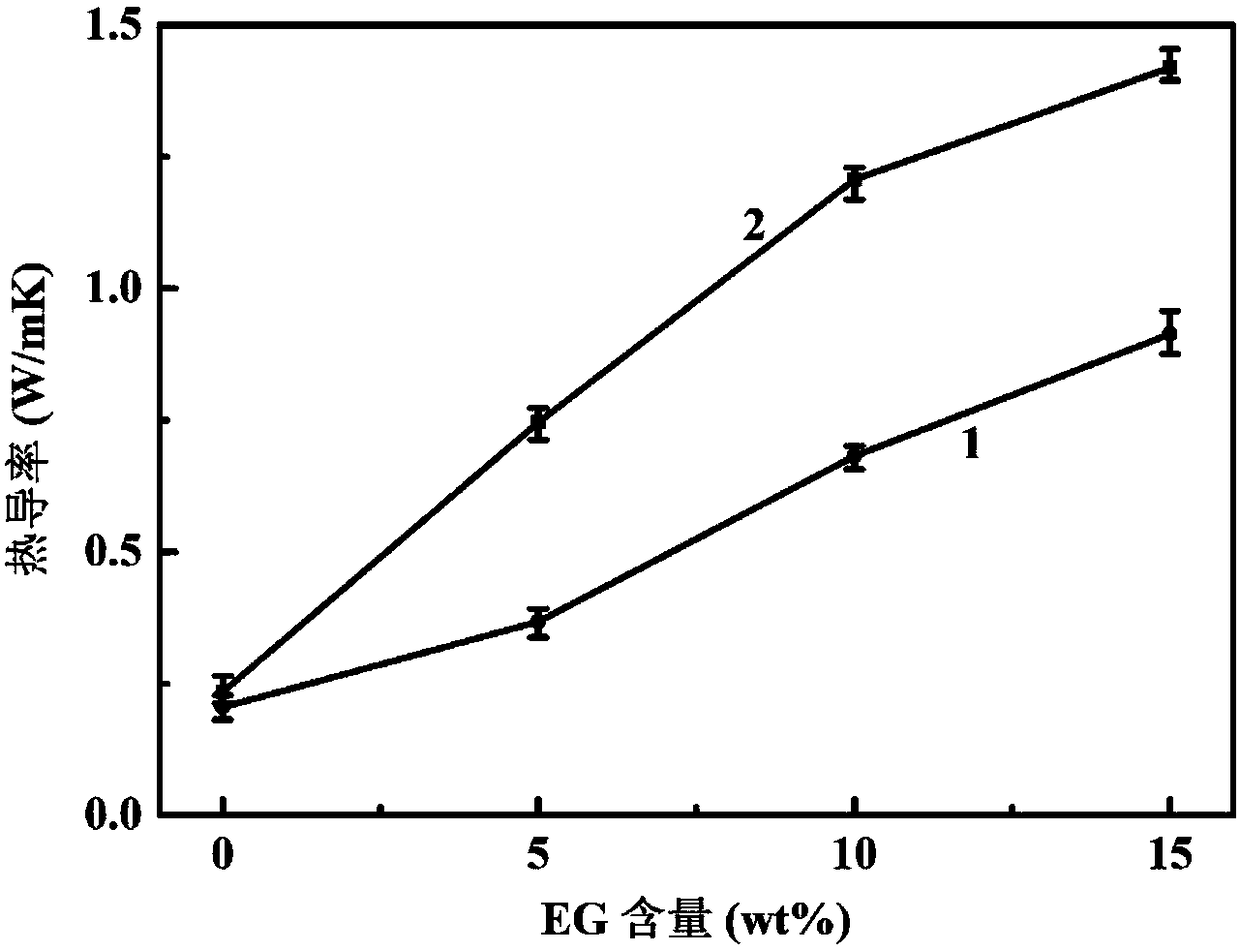

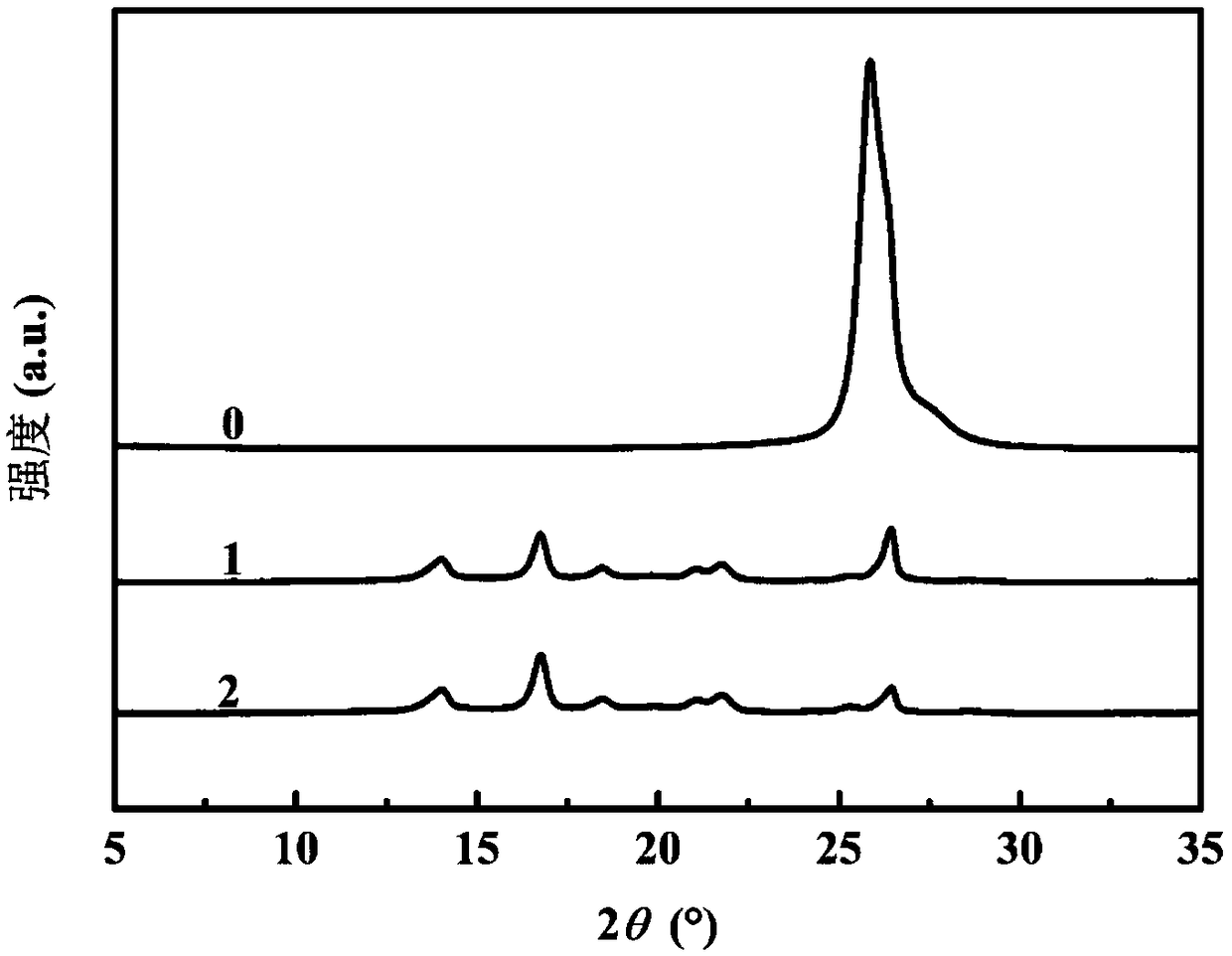

[0033] Premix PP and PP-g-MA pellets and EG powder according to the mass ratio of 85:10:5, and then feed from the feeding port ( figure 1 Section I) is added into the extruder for melting and kneading; when the me...

Embodiment 2

[0035] This embodiment adopts the water-assisted melt kneading extrusion equipment of embodiment 1.

[0036]Premix PP, PP-g-MA pellets and EG powder according to the mass ratio of 80:10:10, then put them into the extruder for melt mixing; when the melt pressure in the water injection section of the extruder reaches above 3MPa, Inject deionized water from the water inlet of the extruder into the melt by means of a metering pump. During the water-assisted melt mixing extrusion process, EG was well stripped and dispersed, and the PP / EG composite material with EG well stripped and dispersed was obtained by extruding at the outlet of the machine head.

[0037] The parts not mentioned are the same as in Example 1.

Embodiment 3

[0039] This embodiment adopts the water-assisted melt kneading extrusion equipment of embodiment 1.

[0040] Premix PP, PP-g-MA pellets and EG powder according to the mass ratio of 75:10:15, then put them into the extruder for melt mixing; when the melt pressure in the water injection section of the extruder reaches above 3MPa, Inject deionized water from the water inlet of the extruder into the melt by means of a metering pump. During the water-assisted melt mixing extrusion process, EG was well stripped and dispersed, and the PP / EG composite material with EG well stripped and dispersed was obtained by extruding at the outlet of the machine head.

[0041] The parts not mentioned are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com