Feeding adjuster of screw extruder

A technology of screw extruder and regulator, applied in the field of screw extruder, can solve the problems of bad influence of screw stability, unstable product quality, equipment and environmental pollution, etc., to solve the problem of extensive material control and avoid scattering and splashing , the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

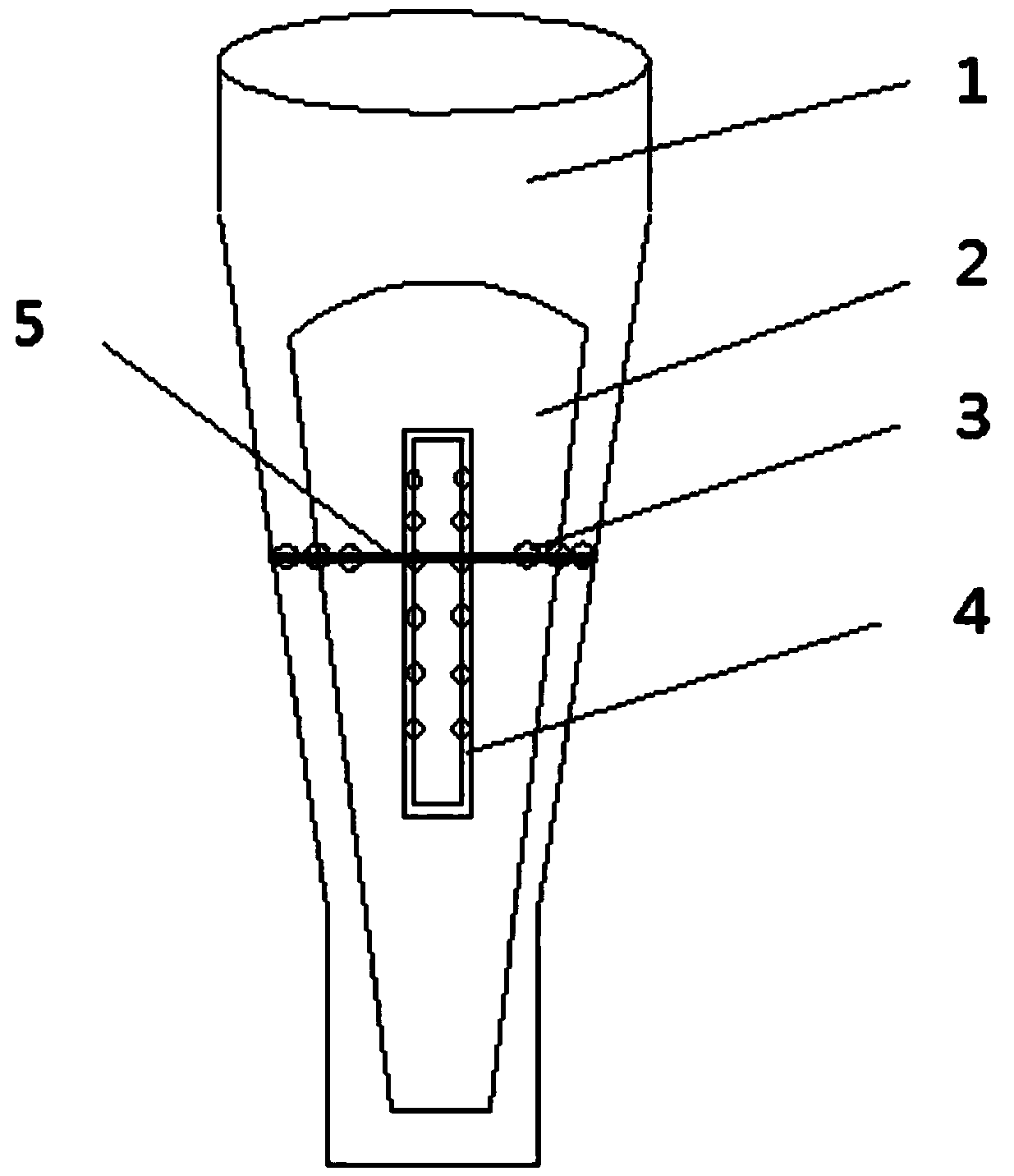

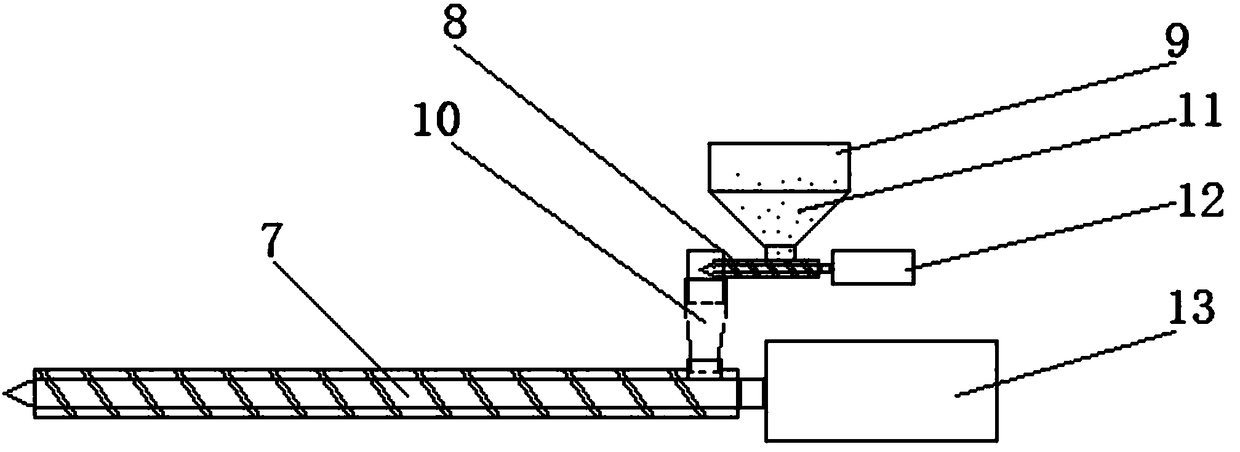

[0026] Example 1, see figure 1 and figure 2 , Invent a preferred embodiment of a feeding regulator for a screw extruder, its improvements are:

[0027] The upper end is used for connecting the sleeve 1 with the feeding screw, and the lower end of the sleeve 1 is used for connecting with the main feeding screw;

[0028] The adjustment piece 2 provided in the sleeve 1 through the transfer structure, the adjustment sheet 2 can rotate in the sleeve 1; the transfer structure includes The installation hole 3 on the 1 and the adjustment rod 5 connected with the installation hole 3, and the adjustment block 4 used to connect the adjustment sheet 2 and the adjustment rod 5, the front of the adjustment block 4 and the adjustment block 4 The back of the adjustment piece 2 is connected, the back of the adjustment block 4 is connected with the adjustment rod 5 through a height adjustment structure, and the adjustment rod 5 is connected with the installation hole 3 through a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com