Method and apparatus for swirling flow strengthened biodegradation treatment of sewage

A biodegradation and sewage technology, applied in the field of water treatment, can solve the problems of low sewage treatment efficiency and poor economy, and achieve the effects of improving nutrient removal rate, biodegradability, and denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

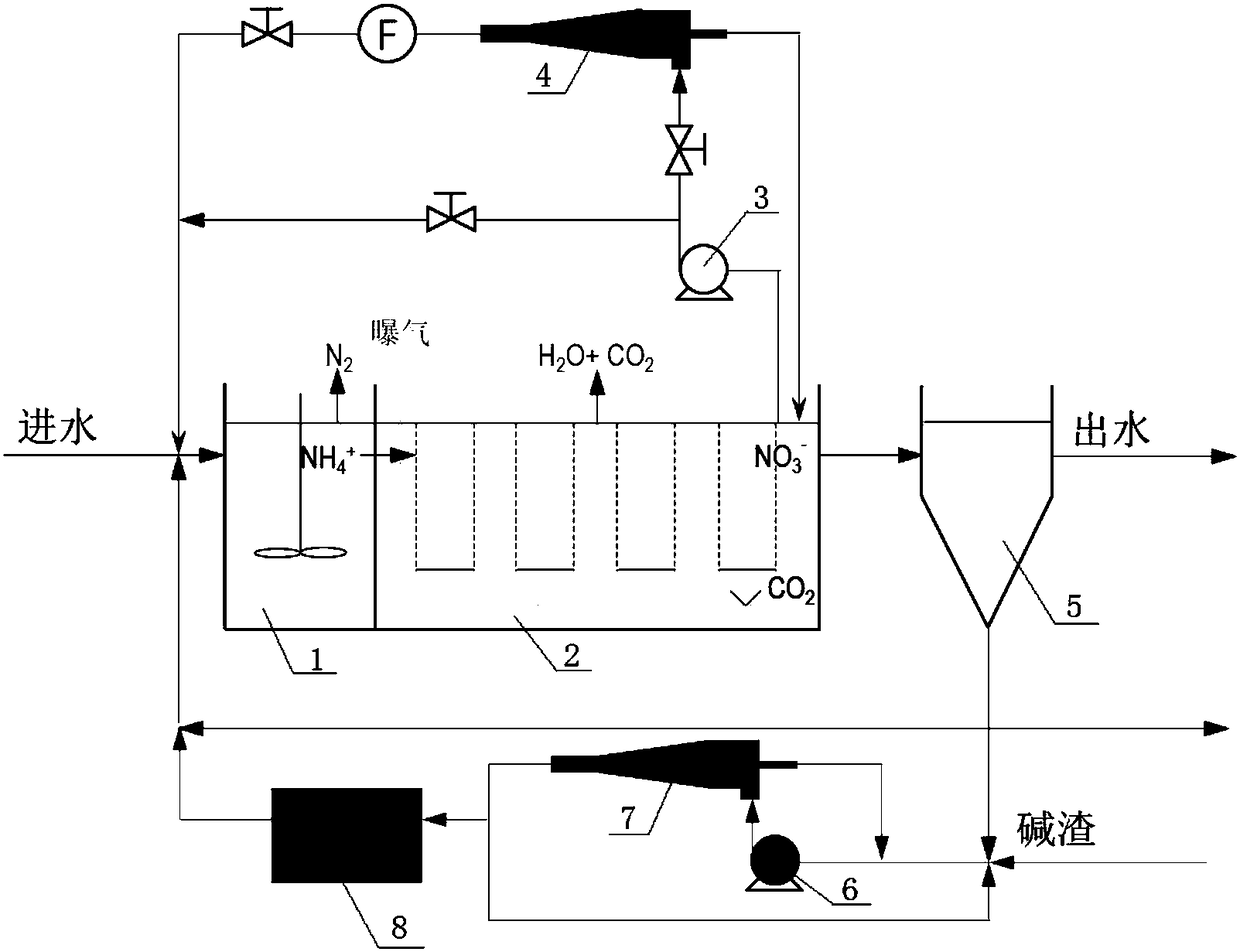

Image

Examples

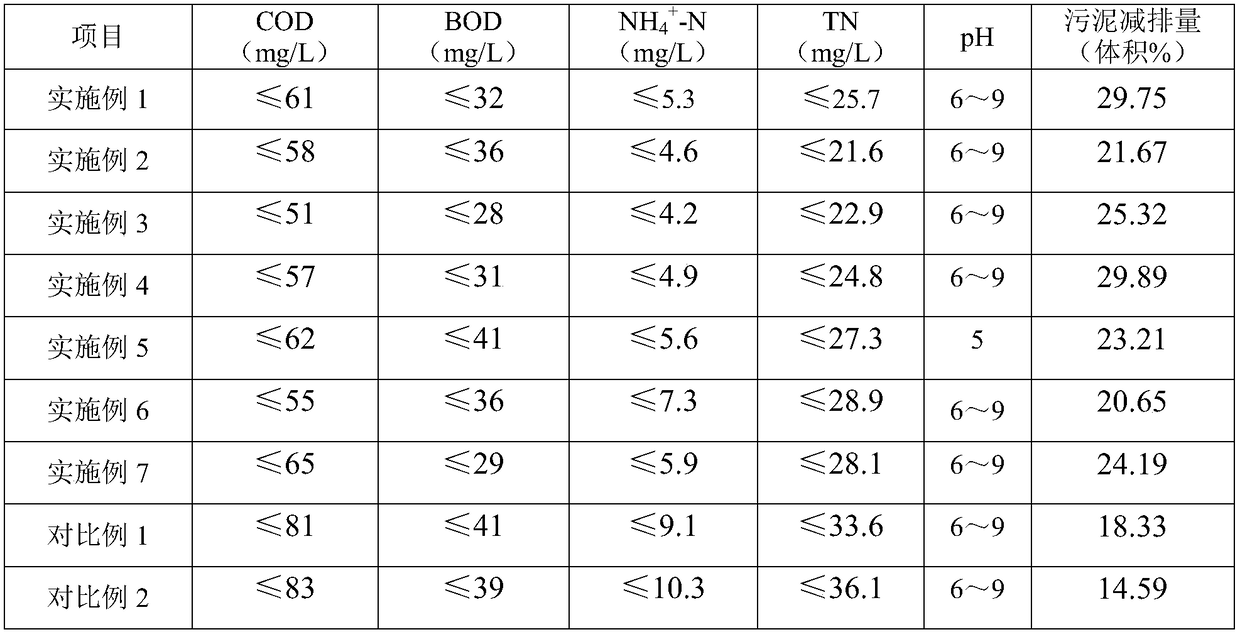

Embodiment 1

[0075] a. The mixture of sewage and activated sludge (the volume ratio of sewage and activated sludge is 300:1) is subjected to anoxic treatment in anoxic tank 1 (time is 2 hours, DO concentration is 0.5mg / L);

[0076] b. Carry out aerobic treatment (time is 6 hours, DO concentration is 2mg / L) in aerobic tank 2 with the mixture obtained after anoxic treatment, obtain mixed material A;

[0077] c. Part of the mixed material A enters the sludge breaking cyclone 4 (pressure drop is 0.1MPa) through the circulating reflux pump 3 for cyclone breaking treatment, and the overflow of the sludge breaking cyclone 4 The reflux ratio is 4% by volume, the DO concentration in the material obtained after the cyclone breaking treatment is 1 mg / L, and the median particle diameter of the activated sludge in the material is 46.23 μm. After the cyclone breaking treatment The material returned in the anoxic tank 1, the circulation reflux ratio of the reflux process in the cycle is 5; the mixed mate...

Embodiment 2

[0079] a. The mixture of sewage and activated sludge (the volume ratio of sewage and activated sludge is 100:1) is subjected to anoxic treatment in anoxic tank 1 (time is 3 hours, DO concentration is 0.1mg / L);

[0080] b. Carry out aerobic treatment (time is 5 hours, DO concentration is 3mg / L) in aerobic tank 2 with the mixture obtained after anoxic treatment, obtain mixed material A;

[0081] c. Part of the mixed material A enters the sludge breaking cyclone 4 (pressure drop is 0.1MPa) through the circulating reflux pump 3 for cyclone breaking treatment, and the overflow of the sludge breaking cyclone 4 The reflux ratio is 4% by volume, the DO concentration in the material obtained after the cyclone breaking treatment is 0.8 mg / L, and the median particle size of the activated sludge in the material is 25 μm. After the cyclone breaking treatment The material returned in the anoxic tank 1, the circulation reflux ratio of the reflux process in this cycle is 10; the mixed material ...

Embodiment 3

[0083] a. The mixture of sewage and activated sludge (the volume ratio of sewage and activated sludge is 500:1) is subjected to anoxic treatment in anoxic tank 1 (time is 1 hour, DO concentration is 0.6mg / L);

[0084] b. Carry out aerobic treatment (time is 9 hours, DO concentration is 4mg / L) in aerobic tank 2 with the mixture obtained after anoxic treatment, obtain mixed material A;

[0085] c. Part of the mixed material A enters the sludge breaking cyclone 4 (pressure drop is 0.1MPa) through the circulating reflux pump 3 for cyclone breaking treatment, and the overflow of the sludge breaking cyclone 4 The reflux ratio is 3% by volume, the DO concentration in the material obtained after the cyclone breaking treatment is 0.9 mg / L, and the median particle diameter of the activated sludge in the material is 60 μm. After the cyclone breaking treatment The material returned in the anoxic tank 1, the circulation reflux ratio of the reflux process in the cycle is 2; the mixed materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com