Preparation method for edible enzyme-modified chitosan/walnut protein composite film

A technology of walnut protein and chitosan, applied in flexible coverings, packaging, wrapping paper, etc., can solve the problem of poor mechanical properties, less research on chitosan/walnut protein composite films, mechanical properties and barrier properties of ordinary protein films Poor and other problems, to achieve the effect of enhanced mechanical properties and barrier properties, high health care function and food value, and excellent natural antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

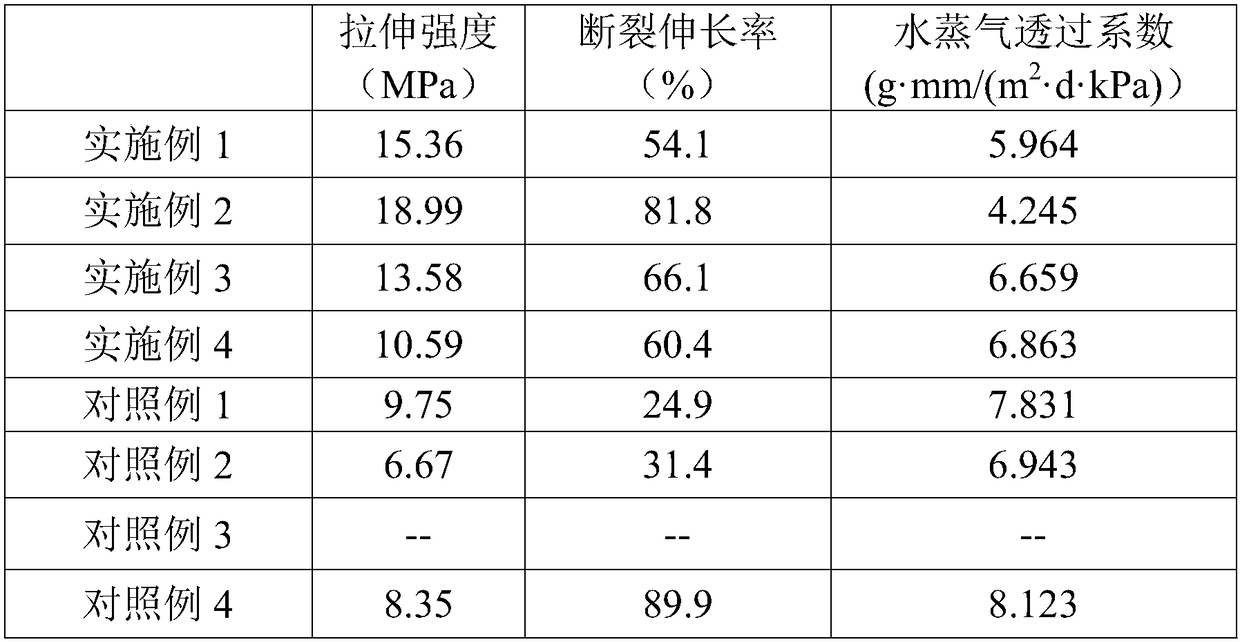

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of enzyme modified chitosan / walnut protein composite film

[0029] Configure 5% walnut protein solution to stir well, and add 3% chitosan to mix, add 3% glycerin to mix, add 0.09% glutaraldehyde to mix, and the amount of transglutaminase added is 15U / g protein, Adjust the pH to 8, heat in a water bath at 50°C for 3h, inactivate the enzyme at 85°C for 3min after the reaction is complete, and sonicate at 200W for 15min after cooling, then filter to remove air bubbles. Pour the filtered membrane solution into a flat container, air-dry it in an oven at 60°C for 3 hours, put it in an environment with a relative humidity of 50% and 25°C for 48 hours after drying, and tear off the film after equilibrium.

Embodiment 2

[0030] Embodiment 2: the preparation of enzyme modified chitosan / walnut protein composite film

[0031] Prepare 4% walnut protein W solution and stir well, add 4% V chitosan for mixing, add 2.5% glycerin for mixing, add 0.09% glutaraldehyde for mixing, and the amount of transglutaminase added is 15U / g For the protein, adjust the pH to 8, heat in a water bath at 50°C for 3 hours, inactivate the enzyme at 85°C for 3 minutes after the reaction is completed, sonicate at 200W for 15 minutes after cooling, and then filter to remove air bubbles. Pour the filtered membrane solution into a flat container, air-dry it in an oven at 60°C for 3 hours, put it in an environment with a relative humidity of 50% and 25°C for 48 hours after drying, and tear off the film after equilibrium.

Embodiment 3

[0032] Embodiment 3: the preparation of enzyme modified chitosan / walnut protein composite film

[0033] Configure 3% walnut protein solution to stir well, and add 5% chitosan for mixing, add 2.5% glycerin for mixing, add 0.08% glutaraldehyde for mixing, and the amount of transglutaminase added is 25U / g protein, Adjust the pH to 9, heat in a water bath at 60°C for 2h, inactivate the enzyme at 85°C for 3min after the reaction is complete, and sonicate at 200W for 15min after cooling, then filter to remove air bubbles. Pour the filtered membrane solution into a flat container, air-dry it in an oven at 60°C for 3 hours, put it in an environment with a relative humidity of 50% and 25°C for 48 hours after drying, and tear off the film after equilibrium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com