Method for extracting millipede protein hydrolysates and application thereof

A technology of hydrolyzing protein and extracting methods, applied in the direction of peptide preparation methods, applications, chemical instruments and methods, etc., to achieve the effect of high nutritional value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

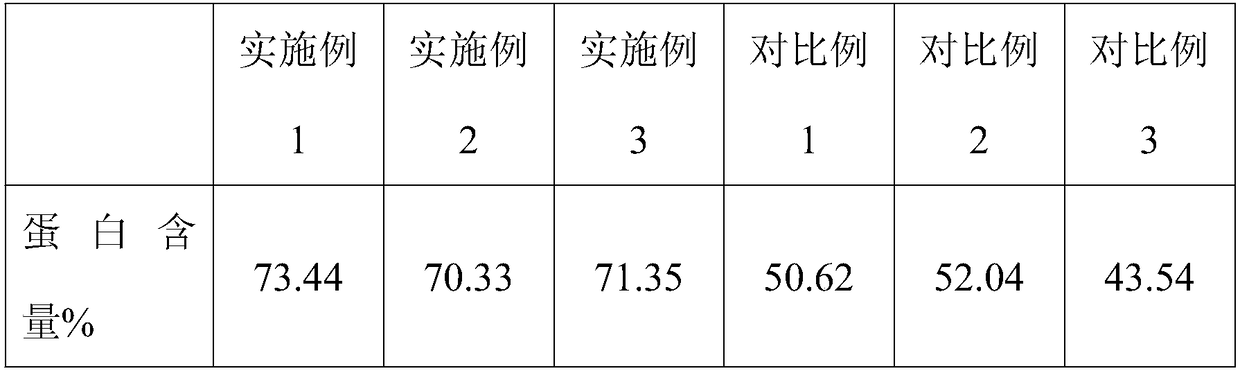

Examples

Embodiment 1

[0024] A method for extracting hydrolyzed protein from millipede, comprising the steps of:

[0025] (1) Collect millipede, after cleaning, process with a high-speed tissue grinder, and the speed of the grinder is 12000r / min;

[0026] (2) Add 12.5 times of distilled water to the crushed millipede tissue in step (1), and then add 4% protease to carry out enzymolysis in a 48°C water bath for 6.5 hours. The protease is composed of papain and subtilisin in proportion to 1 :2 composition;

[0027] (3) Put the millipede tissue after enzymolysis in step (2) into an 88°C water bath and heat for 13 minutes to inactivate the enzyme, and filter to obtain an enzymolysis solution;

[0028] (4) The enzymolysis solution in step (3) is first filtered by an ultrafiltration membrane with a molecular weight of 30,000 Daltons, and then filtered and concentrated by an ultrafiltration membrane with a molecular weight of 500 Daltons to obtain a hydrolyzed protein of millipede of concentrate.

Embodiment 2

[0030] A method for extracting hydrolyzed protein from millipede, comprising the steps of:

[0031] (1) Collect millipede, after cleaning, process it with a high-speed tissue grinder, and the speed of the grinder is 10000r / min;

[0032] (2) Add 10 times of distilled water to the crushed millipede tissue in step (1), then add 2% protease and carry out 5h enzymolysis in a 45°C water bath, the protease is composed of papain and subtilisin in proportion 1: 1 composition;

[0033] (3) Put the millipede tissue after enzymatic hydrolysis in step (2) into an 85°C water bath and heat for 10 minutes to inactivate the enzyme, and filter to obtain an enzymatic hydrolysis solution;

[0034] (4) The enzymolysis solution of step (3) is first filtered by an ultrafiltration membrane with a molecular weight of 40,000 Daltons, and then filtered and concentrated by an ultrafiltration membrane with a molecular weight of 500 Daltons to obtain a hydrolyzed protein of millipede of concentrate.

Embodiment 3

[0036] A method for extracting hydrolyzed protein from millipede, comprising the steps of:

[0037] (1) Collect millipede, after cleaning, process it with a high-speed tissue grinder, and the speed of the grinder is 13000r / min;

[0038] (2) Add 15 times of distilled water to the crushed millipede tissue in step (1), then add 6% protease and carry out 8h enzymolysis in a water bath at 50°C, the protease is composed of papain and subtilisin in proportion 1: 3 composition;

[0039] (3) Put the millipede tissue after enzymolysis in step (2) into a 90°C water bath and heat for 15 minutes to inactivate the enzyme, and filter to obtain an enzymolysis solution;

[0040] (4) The enzymolysis solution of step (3) is first filtered by an ultrafiltration membrane with a molecular weight of 50,000 Daltons, and then filtered and concentrated by an ultrafiltration membrane with a molecular weight of 500 Daltons to obtain a hydrolyzed protein of millipede of concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com