Connection nodes and connection methods of vertically distributed steel bars in prefabricated circular hole plate shear walls

A technology for distributing steel bars and connecting nodes, applied to walls, buildings, building reinforcements, etc., can solve problems such as inconvenient transportation, difficult inspection, and reduced production efficiency, so as to reduce transportation and storage space, improve storage and transportation efficiency, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

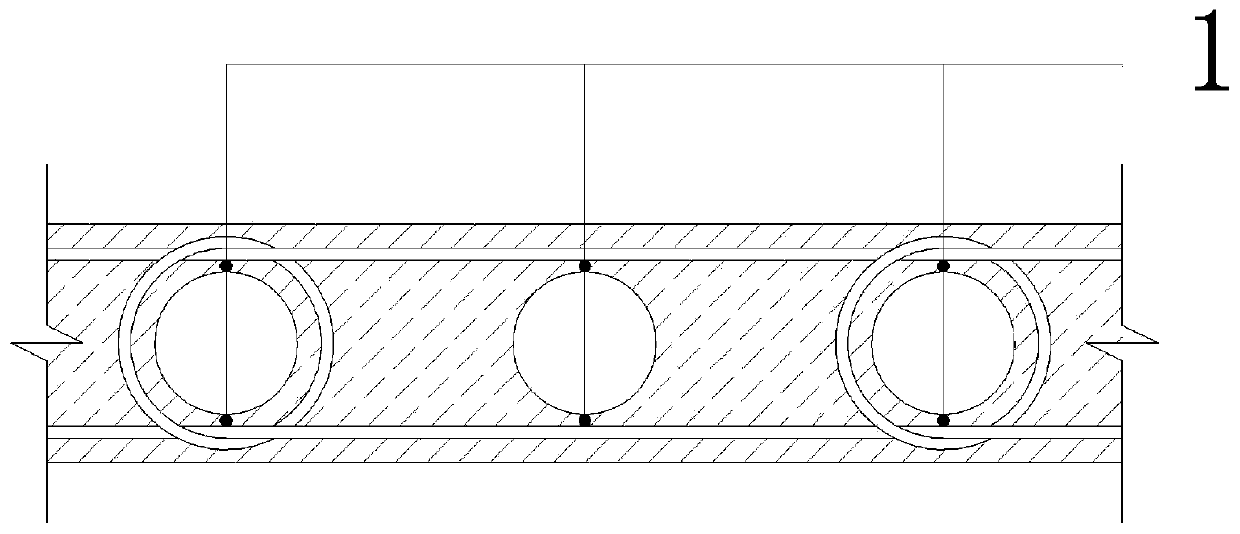

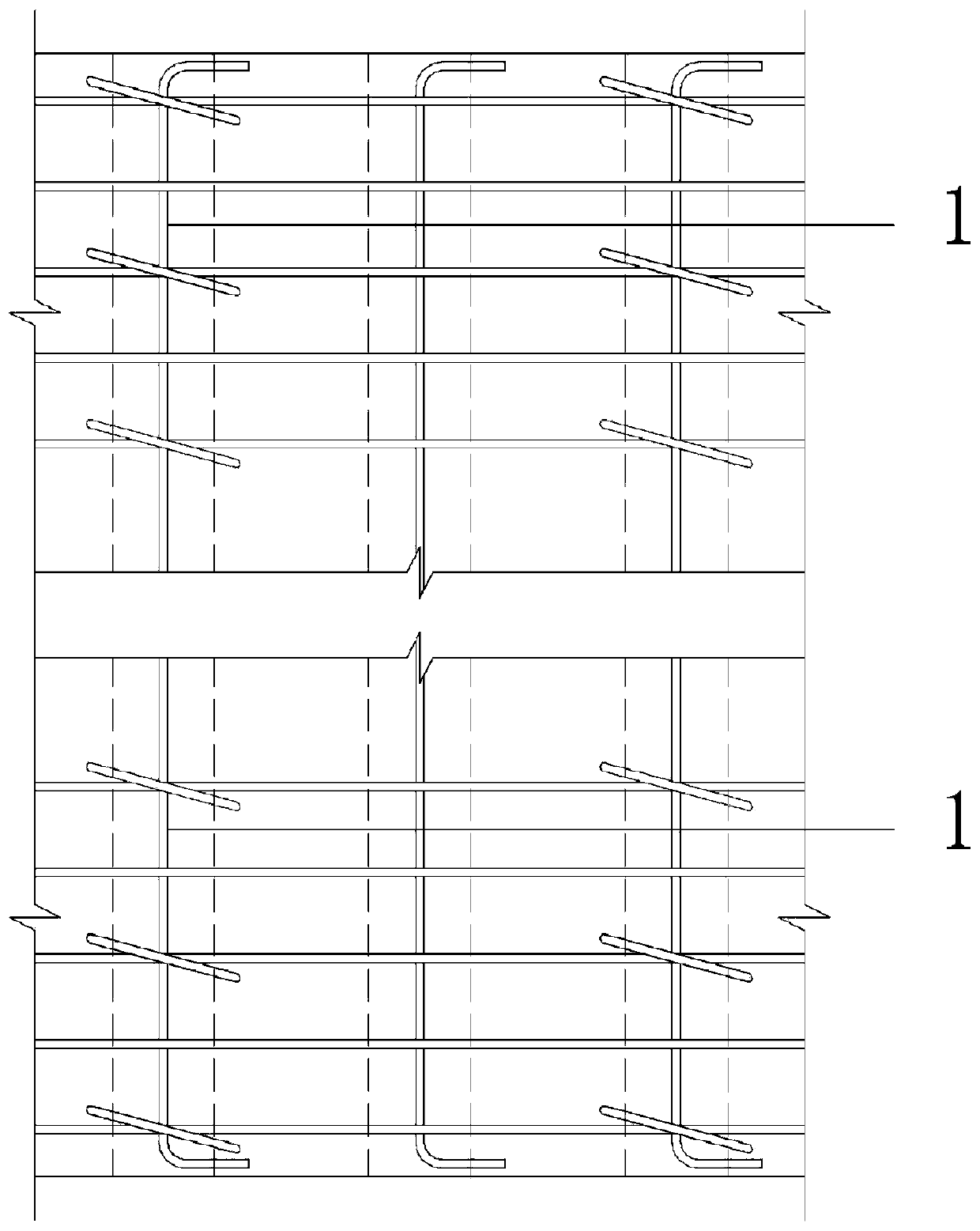

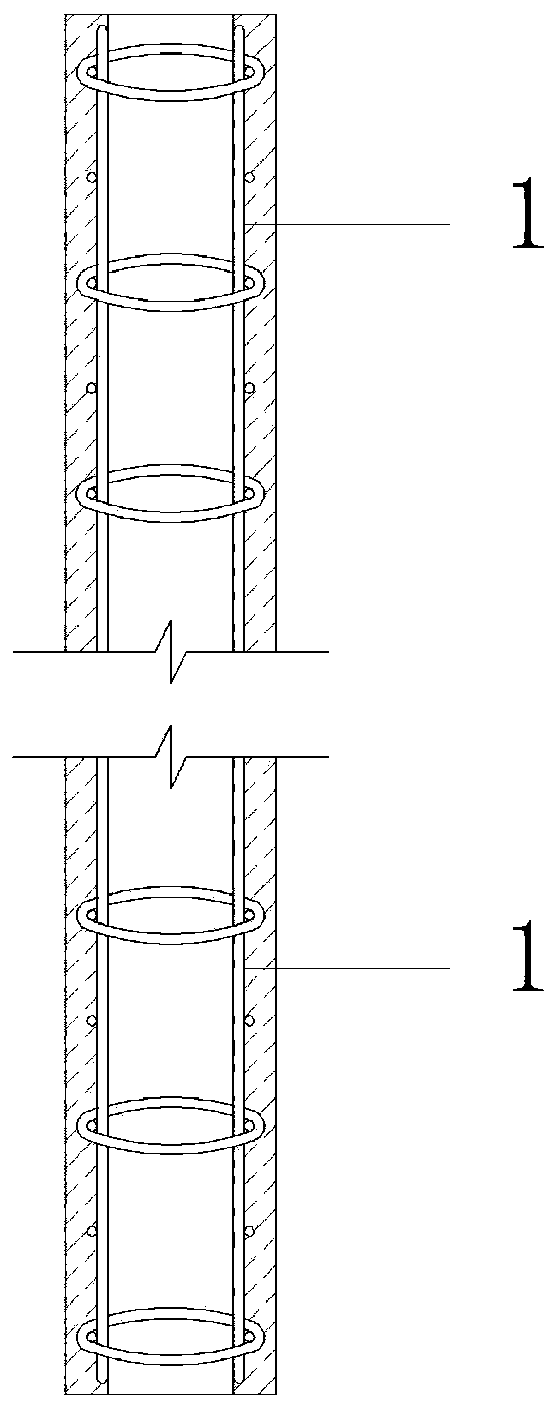

[0043] The connection node of the vertically distributed reinforcement of the prefabricated circular hole plate shear wall, such as Figure 1 to Figure 13As shown, it includes vertically distributed reinforcing bars 1, initial installation layer connecting reinforcing bars 2, connecting reinforcing bars 3, long positioning reinforcing bars 4, short positioning reinforcing bars 5, prefabricated concrete 6, and post-cast concrete 7. The vertically distributed reinforcing bars 1 are placed in The inside of the precast concrete 6 is located closest to the surface of the precast concrete shear wall and is close to the surface of the internal hollow hole; the connecting steel bar 3 is used to connect the upper and lower layers of the prefabricated circular hole plate shear wall vertically distributed steel bars The steel bars are arranged inside the post-cast concrete 7, close to the vertically distributed steel bars 1, and arranged on the same plane along the vertical direction perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com