Remote sensing type material tower weighing device and weighing method

A material tower and remote sensing technology, which is applied to remote sensing material tower weighing equipment and weighing fields, can solve the problems of lack of high-frequency and accurate material tower remaining data, and the inability to track the feed-to-meat ratio information in the whole process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

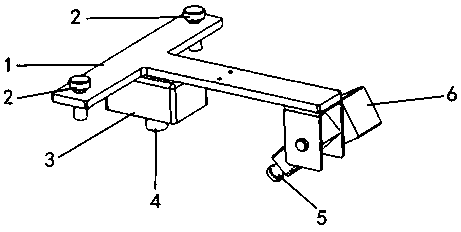

[0090] like figure 1 , Figure 4 , Figure 5 and Figure 7 As shown, a remote-sensing material tower weighing device 20 is installed on the top of the material tower 13, including a T-shaped mounting frame 1, a line laser source 2, an echo receiver 4, a CCD camera 5, a steering gear 6, a central Processor, clock circuit and remote communication transceiver circuit, T-shaped mounting frame 1 is in the shape of "T" in the horizontal direction, and the vertical plane where the central axis of T-shaped mounting frame 1 is located and other vertical planes parallel to it are vertical planes A, namely Figure 4 In the xz plane, set the vertical plane perpendicular to the vertical plane A as the vertical plane B, that is Figure 4 in the yz plane, Figure 4 The xy plane in is a horizontal plane, and two identical line laser sources 2 are symmetrically installed on both ends of the cross bar at the end of the T-shaped mounting bracket 1. There can be only two line laser sources 2...

Embodiment 2

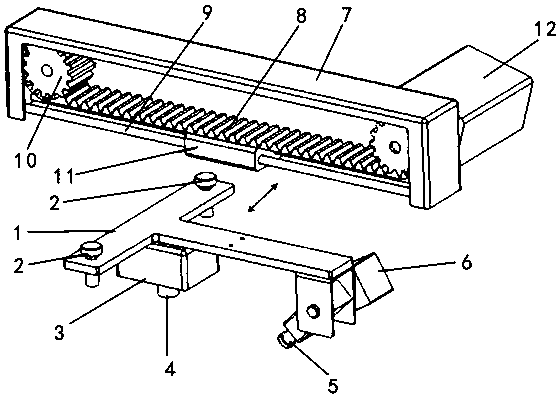

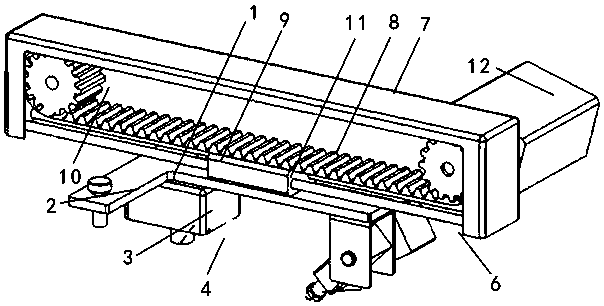

[0107] like figure 2 , image 3 , Figure 4 , Figure 6 and Figure 7 As shown, a remote-sensing material tower weighing device 21 is installed on the top of the material tower 13, including a guide rail mounting bracket 7, a guide rail stepping motor 12, a guide rail gear 10, a guide rail toothed belt 8, a guide rail cross bar 9, and a guide rail Sliding block 11, T-shaped mounting frame 1, line laser source 2, echo receiver 4, CCD camera 5, steering gear 6, central processing unit, clock circuit and remote communication transceiver circuit, two guide rail gears 10 are respectively installed in the closed Inside the two ends of the guide rail toothed belt 8, one of the guide rail gears 10 is installed on the rotating shaft of the guide rail stepper motor 12, and the guide rail sliding block 11 is set outside the horizontal guide rail cross bar 9 and can slide freely and is located on the guide rail tooth belt 8. Below, the top of the guide rail sliding block 11 is connec...

Embodiment 3

[0126] A kind of remote-sensing material tower weighing equipment, on the basis of embodiment 1, a temperature and humidity sensor (not shown in the figure) is added, the signal output end of the temperature and humidity sensor is connected with the temperature and humidity signal input end of the central processing unit connect.

[0127] combine figure 1 , Figure 4 , Figure 5 and Figure 7 , the weighing method adopted by the remote-sensing material tower weighing equipment described in this embodiment includes the following steps:

[0128] Step (6.1): Calculate the wet material density in the material tower 13: the central processing unit obtains the nearby air temperature T and relative humidity h from the temperature and humidity sensor, and the evaporation resistance t of material particles such as feed particles can be obtained through physical experiments. The tower 13 is in a state of heat balance and water vapor balance, and the water content ratio of the wet ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com