Long-stator winding grounding sleeve

A winding grounding, long stator technology, applied in the winding, connection with the grounding device, electric components, etc., can solve the problems of cable surface damage, air breakdown, sleeve loosening, etc., to avoid damage, eliminate gap changes, close contact big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

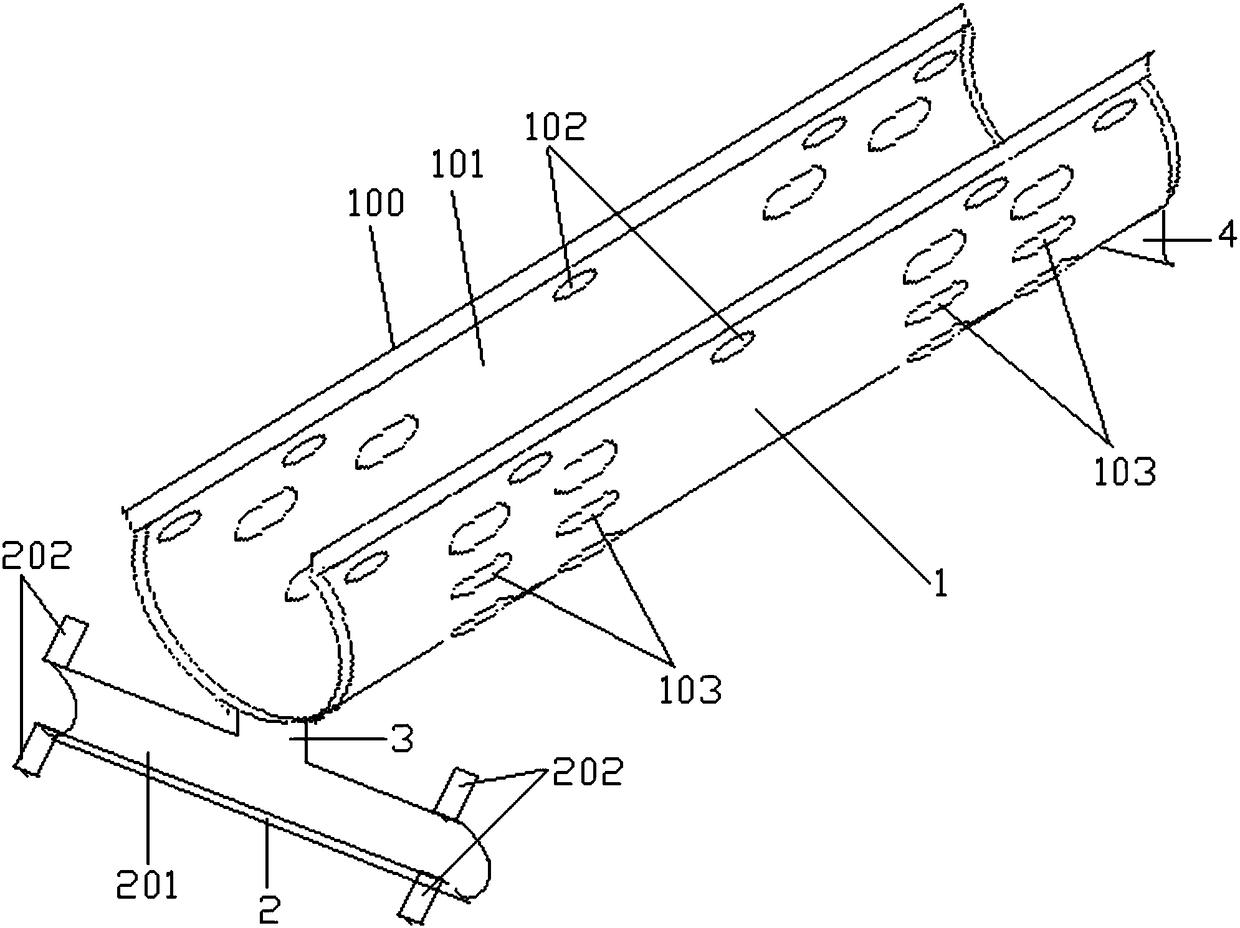

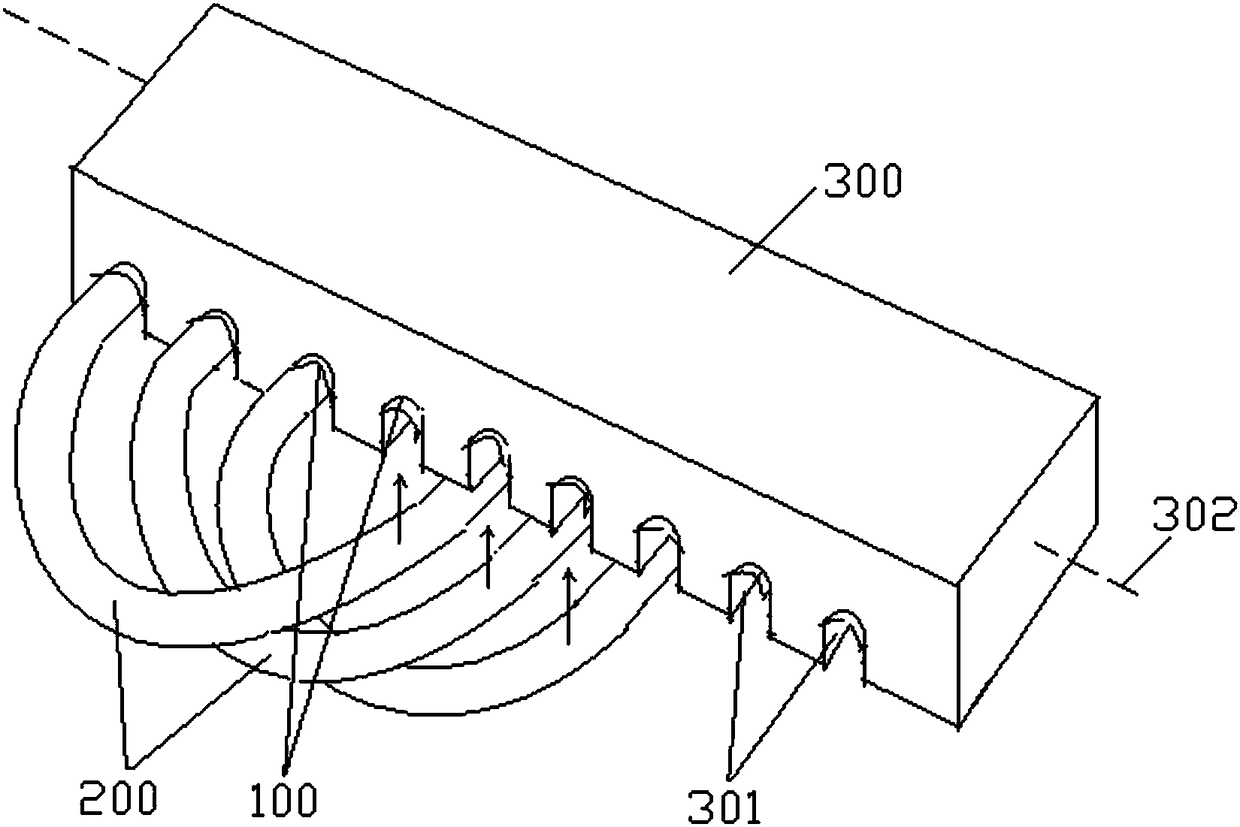

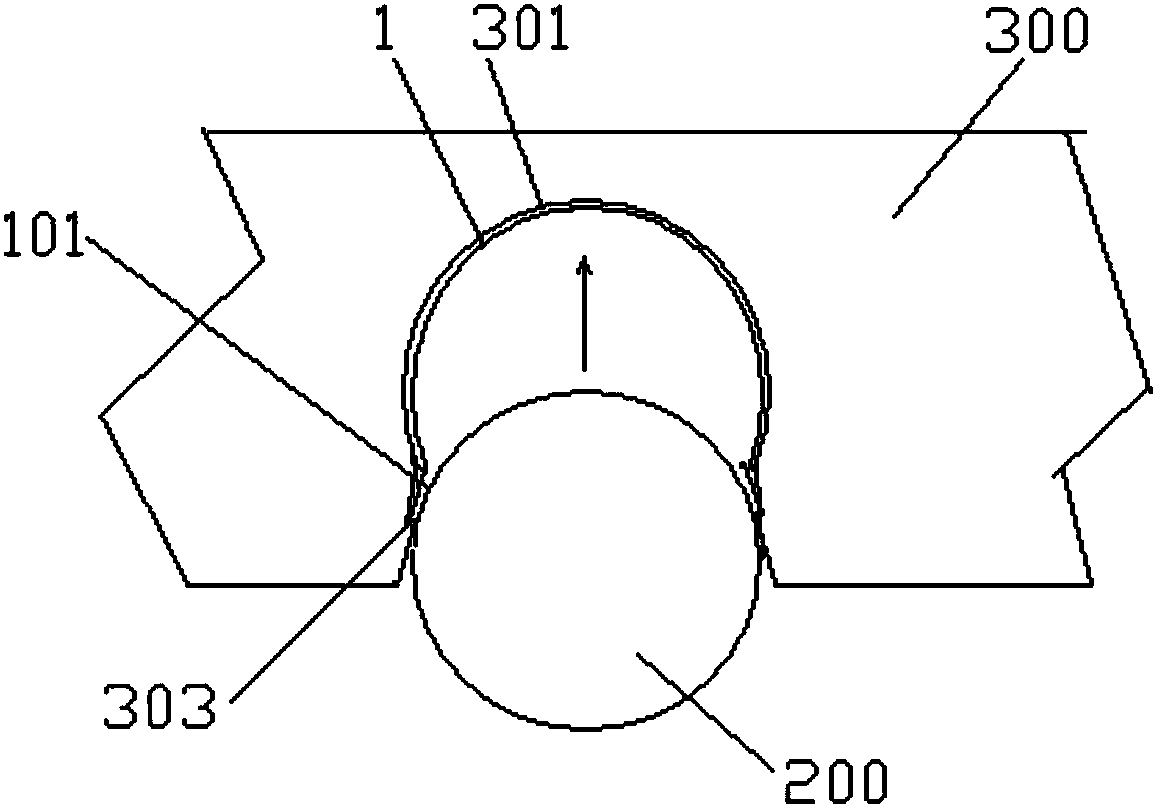

[0042] Such as Figure 1 to Figure 8 As shown, an embodiment of the long stator winding grounding bushing of the present invention. As known to those skilled in the art, in the long stator linear motor structure, a plurality of grooves 301 are opened on the lower surface of the long stator 300, and the grooves 301 extend in a direction perpendicular to the longitudinal axis 302 of the long stator 300 and traverse the long stator 300, all the grooves 301 are arranged at intervals along the extending direction of the longitudinal axis 302 of the long stator 300 to accommodate the three-phase AC windings, that is, the winding cables 200 are accommodated in the grooves 301, and the grounding wire 400 is arranged along the longitudinal direction of the long stator 300 The extension direction of the axis 302 is arranged. The long stator winding grounding bushing 100 in the first embodiment is used to realize the connection between the surface layer of the winding cable 200 and the ...

Embodiment 2

[0057] Such as Figure 9 and Figure 10 Shown is another embodiment of the long stator winding grounding sleeve of the present invention. This second embodiment is basically the same as the above-mentioned first embodiment, and the similarities will not be repeated. The difference is: in this second embodiment, see Figure 9 The opening direction of the opening groove 201 of the connection element 2 is opposite to that of the opening 101 of the sleeve body 1 . see Figure 10 , when the bushing body 1 is placed in the groove 301 of the long stator 300, its opening 101 faces downward, and the opening of the opening slot 201 of the connecting element 2 faces upward, so when the ground wire 400 is accommodated in the opening slot 201, the connecting element 2 Covering the ground wire 400 under the ground wire 400 can play a role in supporting the ground wire 400, so that the ground wire 400 can be placed in the open slot 201 very conveniently.

[0058] In addition, in the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com