Vector control method of open-winding permanent magnet synchronous motor with suppressed zero-sequence current

A technology of permanent magnet synchronous motor and zero-sequence current, which is applied to the vector control of open-winding permanent magnet synchronous motor and needs wide speed regulation. It can solve the problem that the voltage output capacity of the inverter is not fully utilized and affects the stability of the motor. and operating efficiency, not conforming to the compact layout of electric vehicles, etc., to achieve the effect of improving voltage utilization, reducing loss and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

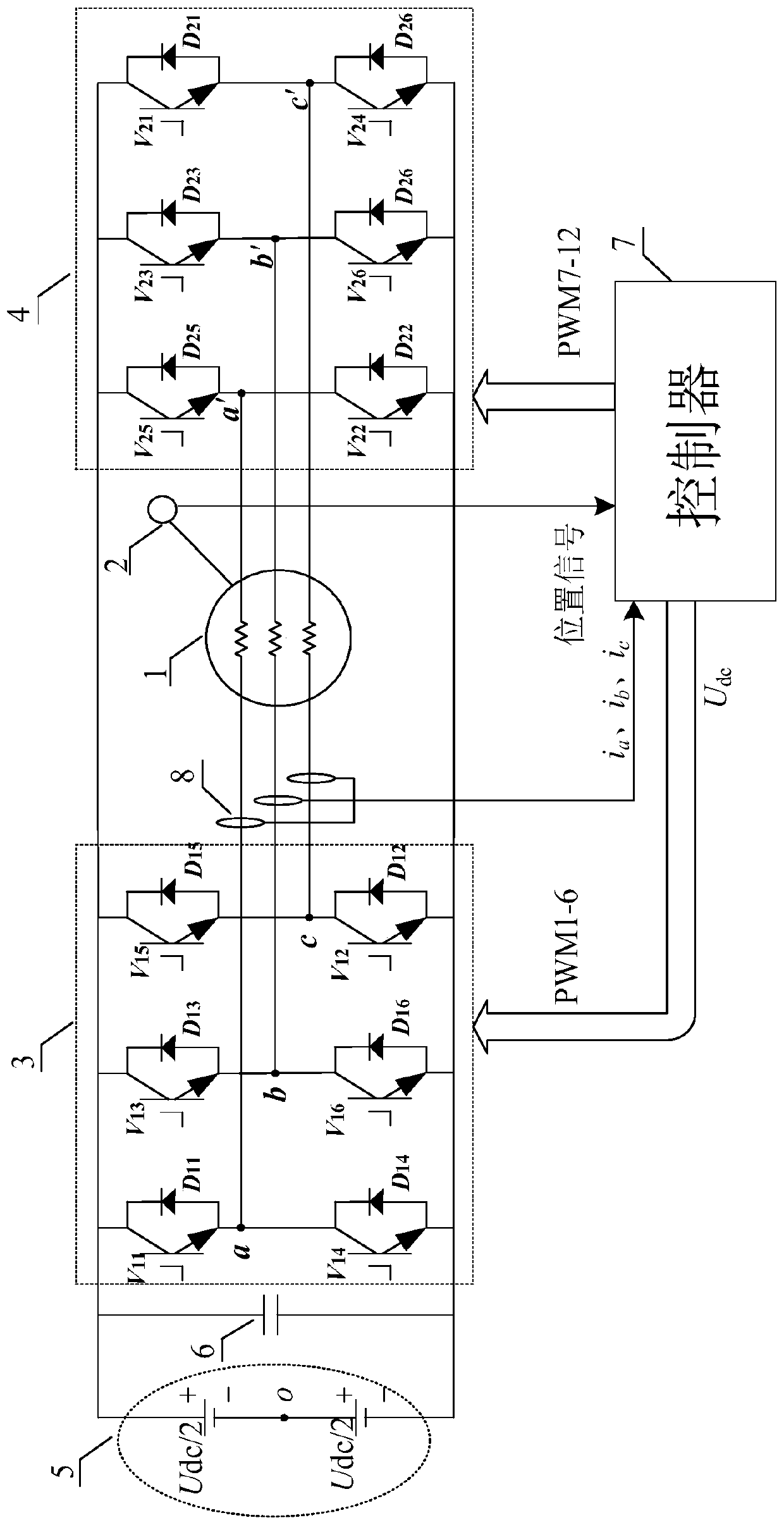

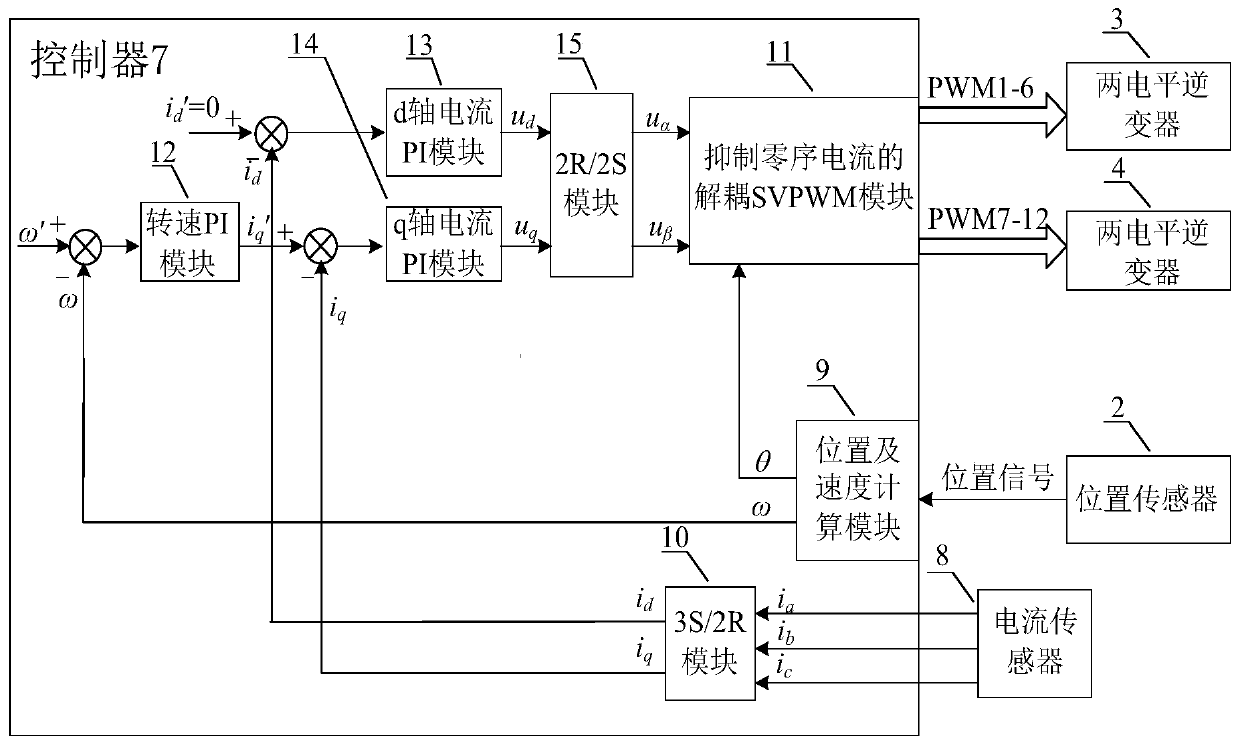

[0025] figure 1 A permanent magnet synchronous motor vector control drive system with open winding structure for electric vehicle zero-sequence current suppression, including a controller 7 and two identical two-level inverters 3, 4, two identical two-level inverters Devices 3 and 4 both have a three-leg structure, and each bridge arm is composed of two IGBT switching devices (V 11 , V 13 , V 15 , V 14 , V 16 , V 12 , V 21 , V 23 , V 25 , V 24 , V 26 , V 22 ) and reverse diodes (D 11 、D 13 、D 15 、D 14 、D 16 、D 12 、D 21 、D 23 、D 25 、D 24 、D 26 、D 22 )composition. The two two-level inverters 3 and 4 are simultaneously powered by a DC power supply 5 , and electrolytic capacitors 6 are connected in parallel at both ends of the DC power supply 5 . The neutral point of the winding of the permanent magnet synchronous motor 1 is opened, leading to 6 output terminals respectively a, b, c, a', b', c'; aa', bb', cc' are the permanent magnet synchronous motor 1 Ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com