Method and device for controlling temperature drop in rough rolling process

A rough rolling and control unit technology, applied in the field of metallurgy, can solve problems such as affecting the surface quality of strip steel, affecting the yield of slabs, and unstable rolling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

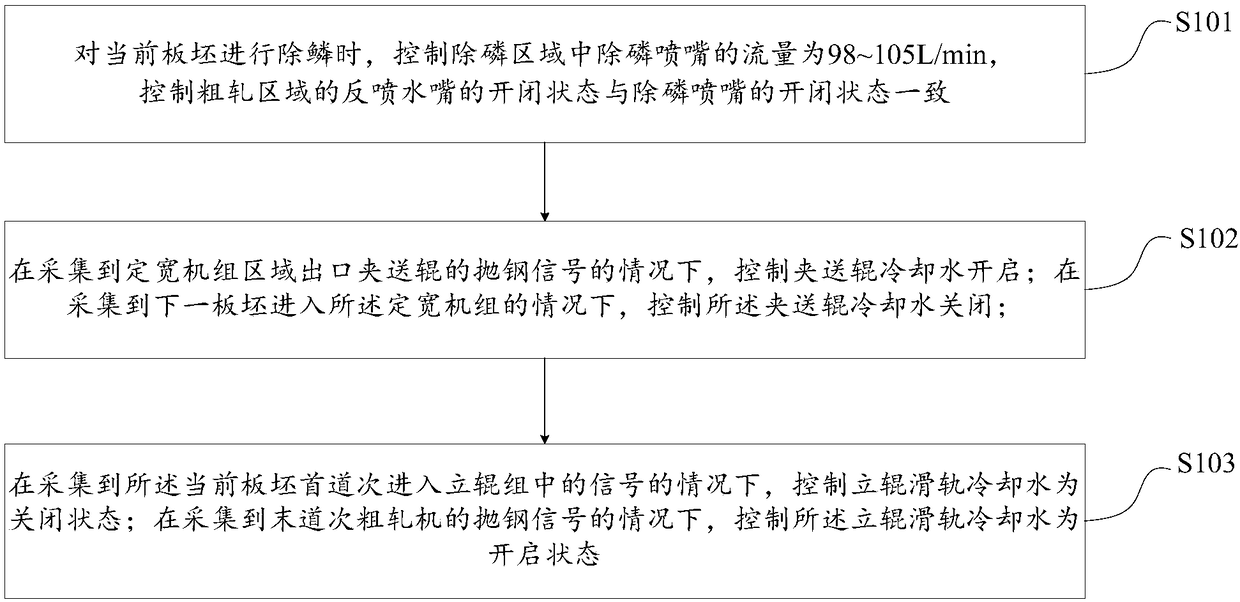

[0052] Corresponding to Embodiment 1, this embodiment also provides a device for controlling the temperature drop in the rough rolling process, such as Image 6 As shown, the device includes: a first control unit 51, a second control unit 52, a third control unit 53, and a fourth control unit 54; wherein,

[0053] Before rolling the slab, it is first necessary to descale the slab. In order to avoid heat conduction between the low-pressure water and the slab when the descaling and rolling is not in use (only the low-pressure water is turned on), the descaling nozzle is provided with a stop valve , the nozzle of the shut-off valve is closed. The first control unit 51 is used to control the flow rate of the descaling nozzle in the descaling area to be 98-105 L / min; preferably 100-102 L / min. Here, the nozzle striking force of the upper header is 0.78N / mm 2 , the impact force of the nozzle of the lower header is 0.84N / mm 2 .

[0054] Of course, not all descaling nozzles have sh...

Embodiment 3

[0065] In practical applications, when using the method provided in Embodiment 1 and the device provided in Embodiment 2 to perform rough rolling temperature drop on a certain type of slab, the specific implementation is as follows:

[0066] Before the slab is rolled, it is first necessary to descale the slab. In order to avoid the heat conduction between the low-pressure water and the slab when the descaling and rolling are not put into use (only the low-pressure water is turned on), the descaling nozzle is provided with a cut-off valve, the nozzle of the shut-off valve is closed.

[0067] During descaling and rolling, the flow rate of the descaling nozzle in the descaling area is controlled to 101.82L / min under the condition of ensuring the striking force. Here, the nozzle striking force of the upper header is 0.78N / mm 2 , the impact force of the nozzle of the lower header is 0.84N / mm 2 .

[0068] Of course, not all descaling nozzles have shut-off valves. There is a nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com