Flexible main splicing system for automobile manufacturing production line

A technology of automobile manufacturing and production line, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of reducing welding work efficiency, increasing working hours, and large floor space, so as to improve space utilization and shorten switching strokes , the effect of shortening the space distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

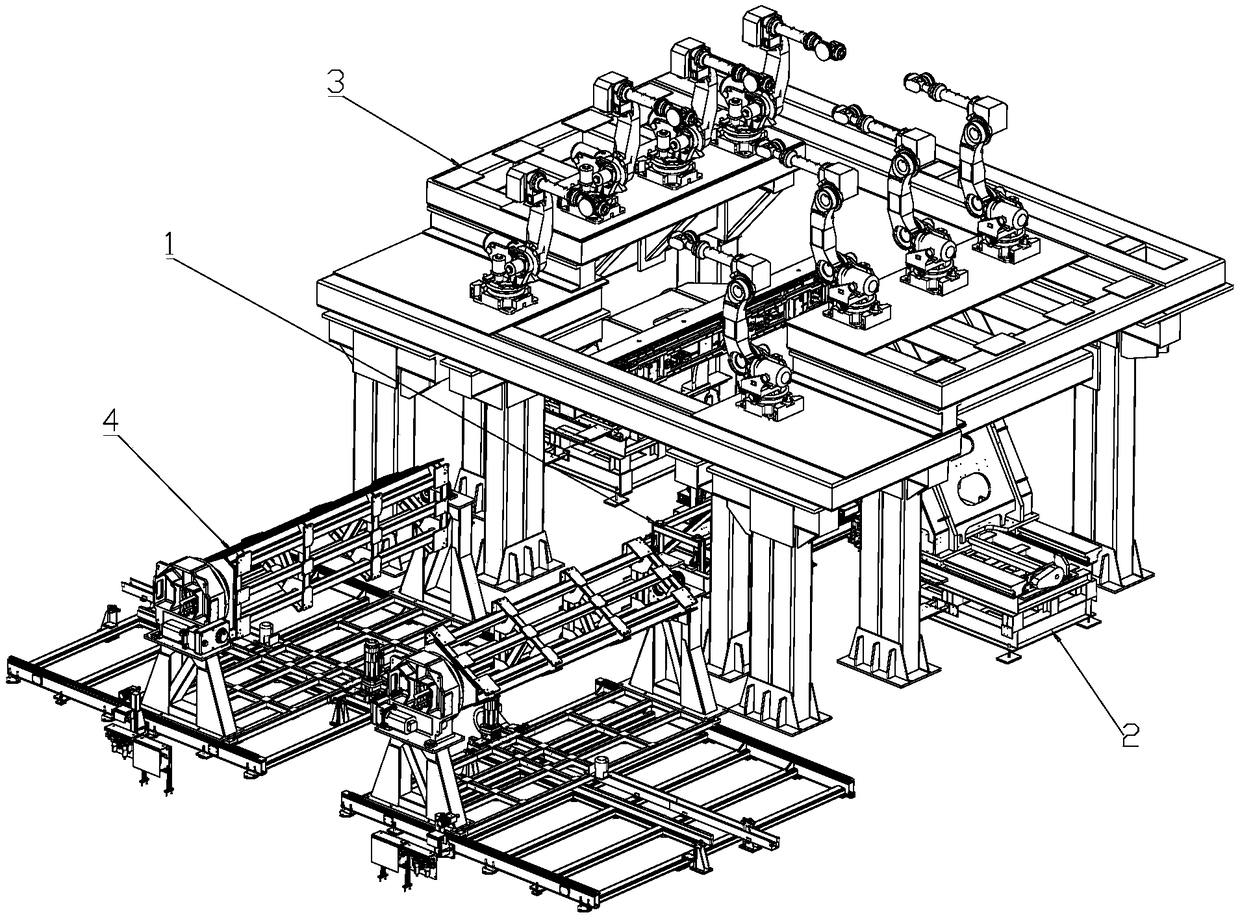

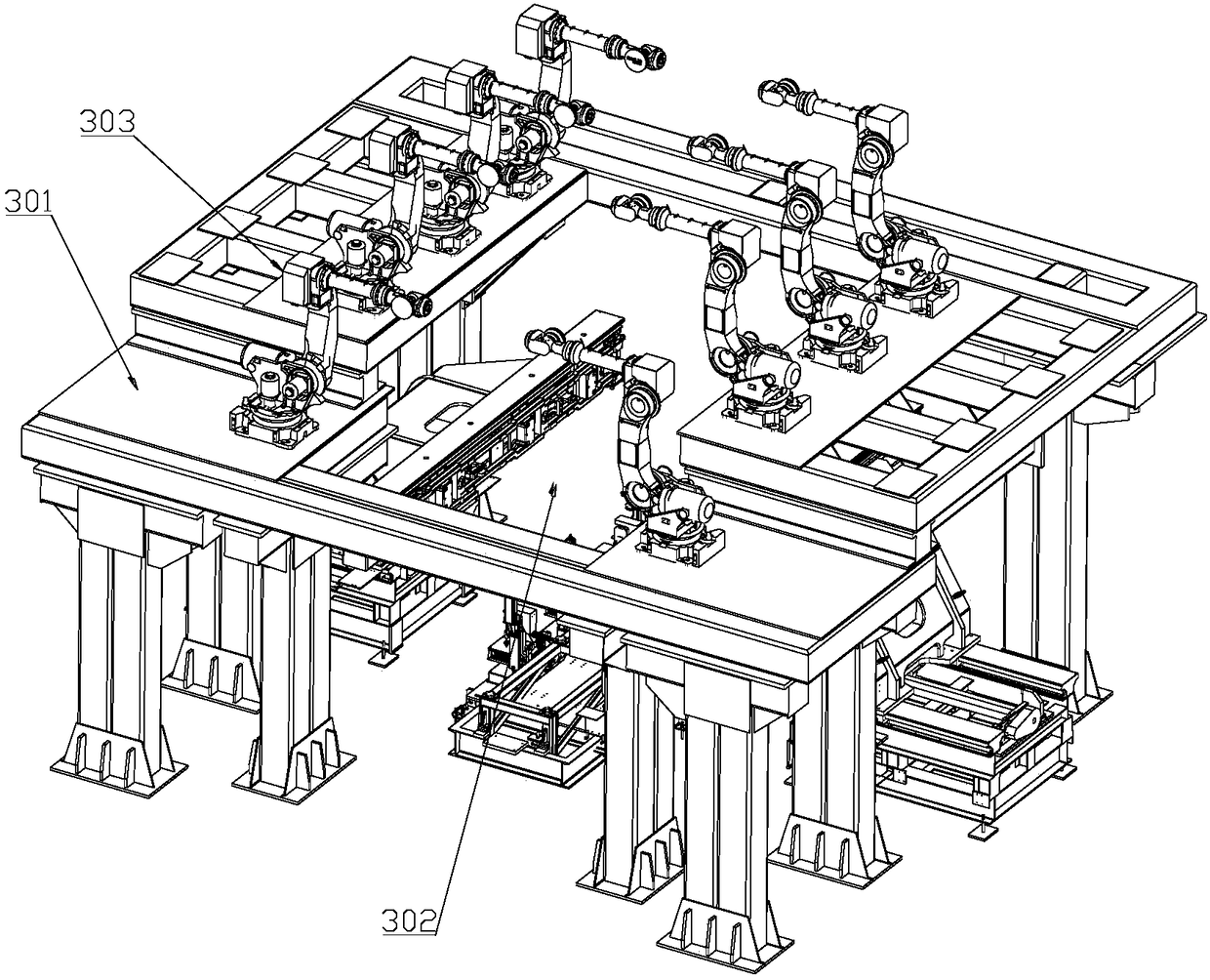

[0018] Such as Figure 1-4 As shown in the figure, a flexible main assembly system of an automobile manufacturing production line is used for automatic welding and assembly of white bodies of different models, including a reciprocating rod type body handling system 1, and side enclosure joints are provided on both sides of the reciprocating rod type body handling system 1 In system 2, a compound robot welding subsystem 3 is provided above the reciprocating rod body handling system 1 , and a clamp storage subsystem 4 is provided on one side of the side enclosure assembly subsystem 3 .

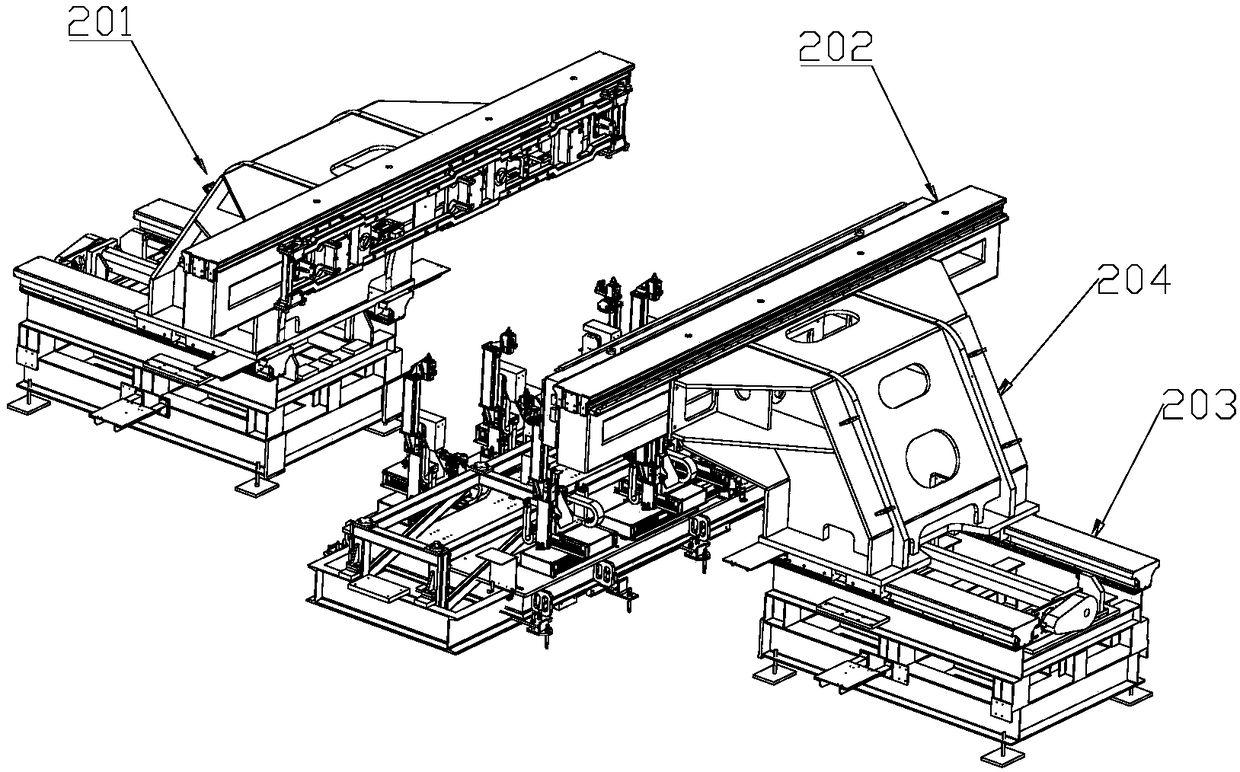

[0019] The side enclosure joining subsystem 2 includes a first side enclosure joining together slide table 201, a second side enclosure joining together slide table 202, the first side enclosure joining together slide table 201...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap