Composite floor and processing method thereof

A technology of a composite floor and a processing method, applied in the field of flooring, can solve the problems of low bonding strength between a surface decoration layer and a plywood base material, poor scratch resistance of the composite floor, easy generation of air bubbles on the board surface, etc. Foaming, not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

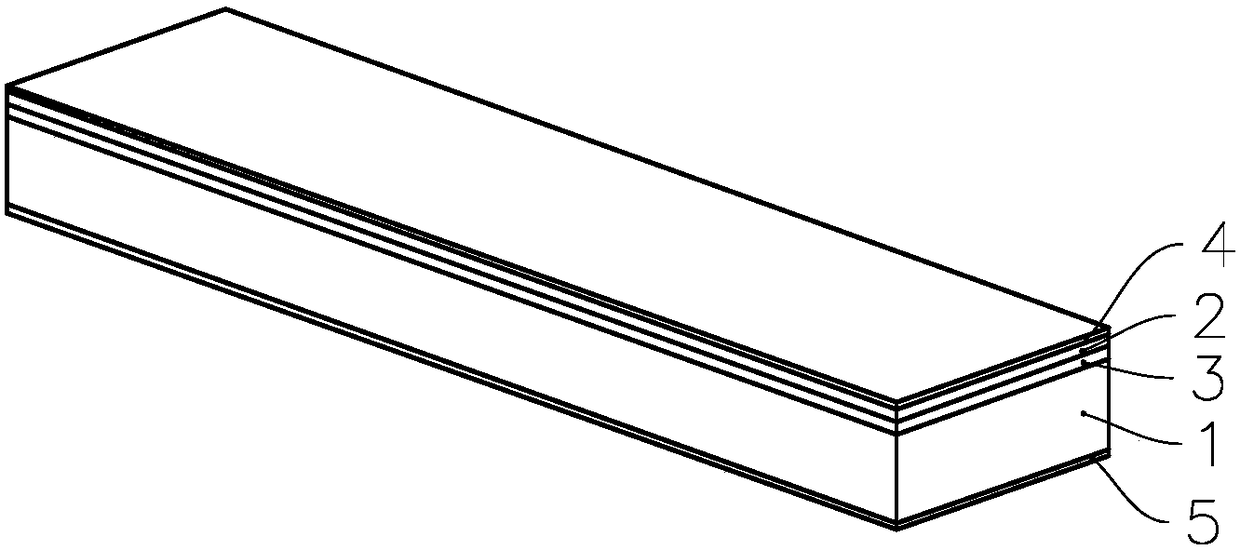

[0019] see figure 1 , figure 1 It is a structural diagram of an embodiment of a composite floor of the present invention. The composite floor of the present invention comprises a base material layer 1 and a decorative surface layer arranged on the front of the base material layer, wherein the base material layer 1 is selected from multi-layer plywood, the decorative surface layer includes a wear-resistant layer 2 and a color film layer 3, the plywood and the color film layer The film layers 3 are connected by an adhesive, and a paint protection layer 4 is arranged on the surface of the wear-resistant layer 2, and the paint protection layer is one of UV light-curing paint, scratch-resistant paint, geothermal-resistant paint or negative ion paint. A protective layer 5 is provided on the back of the plywood, and the protective layer 5 is one of UV light curing paint, balance paper, PE moisture-proof film, EVA static floor mat or aluminum foil. For the convenience of laying, int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com