Reverse osmosis water purifier raw water and backwater mixing ratio control method and water purifier

A technology of reverse osmosis water purifier and mixing ratio, which is applied in the direction of osmosis/dialysis water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. Promotion and other issues to achieve the effect of convenient installation and solving the waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

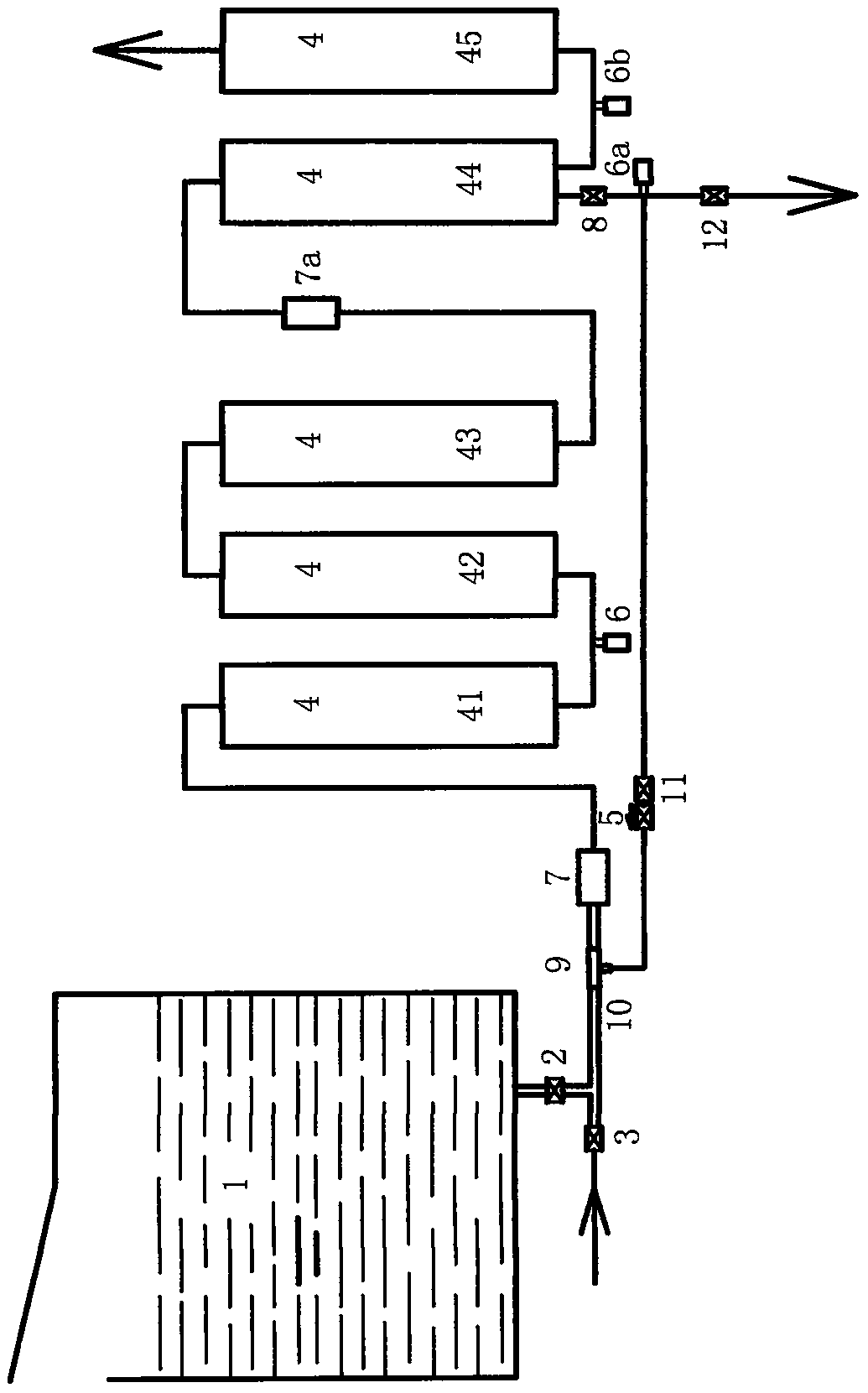

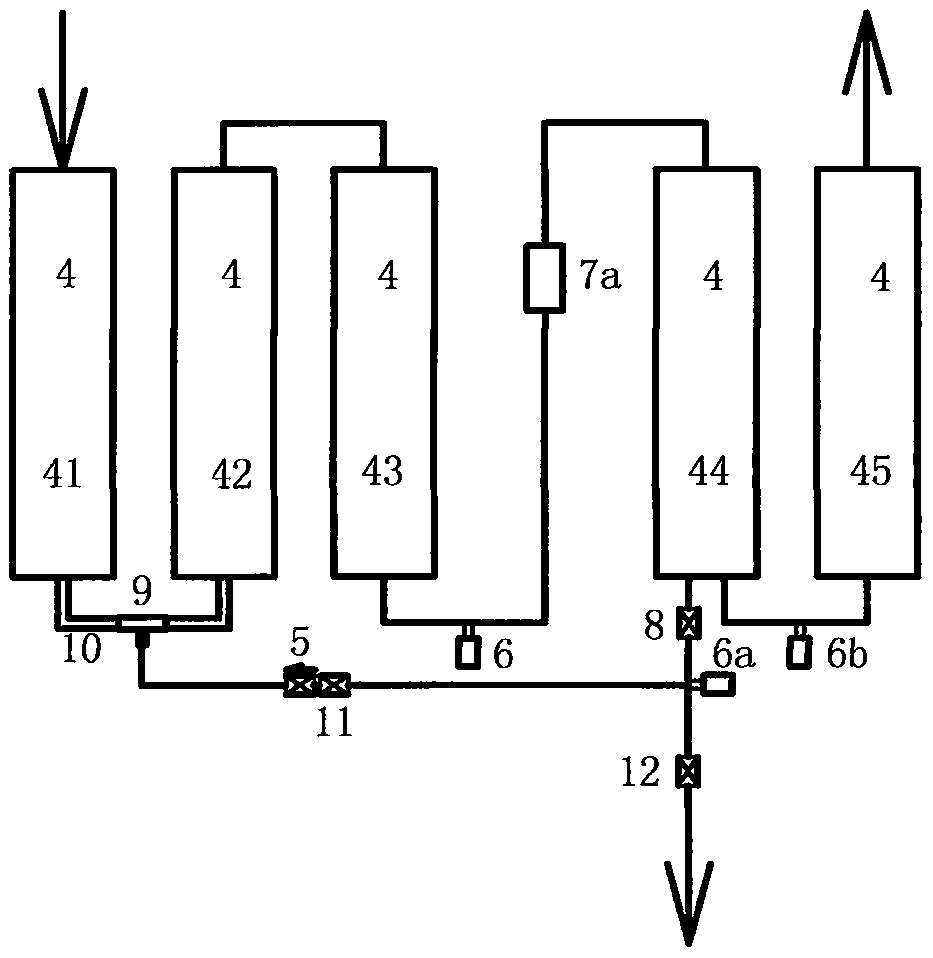

[0018] Example 1. A method for controlling the mixing ratio of raw water and return water in a reverse osmosis water purifier. The reverse osmosis membrane filter 44, the pre-filter 4 connected in series in the pre-pipeline, and the booster pump form a pre-filter channel, wherein the reverse osmosis The water outlet end of the permeable membrane filter gall 44 is connected to the water outlet pipeline, and its concentrated water discharge end is connected to the concentrated water discharge pipeline provided with the concentrated water flow control device 8 and the electric drainage valve 12 in sequence; The water end is connected to the machine in the concentrated water pipeline between the concentrated water flow control device 8 and the electric drain valve 12 . A mixed water ratio control structure with two water inlets and one water outlet connected in series in the pre-filter channel 9: the mixed water outlet and the large-diameter raw water inlet are respectively connec...

Embodiment 2

[0026] Example 2. On the basis of embodiment 1, the water purifier applying the above-mentioned reverse osmosis water purifier raw water and return water mixing ratio control method also includes the RO pump 7a for the reverse osmosis membrane filter gall 44; The RO pump 7a is positioned at the reverse osmosis membrane The water inlet end of the filter gall 44; a plurality of pre-filter galls are arranged between the self-priming pump 7 and the RO pump 7a.

Embodiment 3

[0027] Example 3. On the basis of the above-mentioned embodiments 1 and 2, the water purifier applying the above-mentioned reverse osmosis water purifier raw water and return water mixing ratio control method also includes a raw water pipeline switching valve 2 and an external pipeline valve 3; The water inlet of the first pre-filter 41 of the filtration system is connected with the raw water pipeline switching valve 2 and the external pipeline valve 3, and the water outlet of the raw water pipeline switching valve 2 is connected with the water outlet of the external pipeline valve 3; After closing the external pipeline valve 3 and turning on the raw water pipeline switching valve 2, the water inlet end of the first pre-filter is communicated with the water outlet of the raw water tank 1. When the external pipeline valve 3 is turned on and the raw water pipeline switching valve 2 is closed, the water inlet end of the first pre-filter is communicated with the external pipeline ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap