A kind of method for removing manganese dithionate in manganese ore desulfurization liquid

A technology of manganese dithionate and desulfurization liquid is applied in the field of removing manganese dithionate in the wet desulfurization liquid of manganese ore, which can solve the problems of large investment, large heat consumption, increase the difficulty of cleaning and utilization, etc. The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

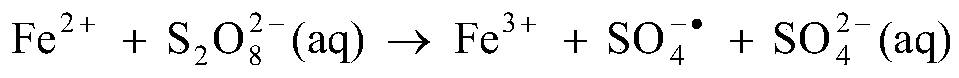

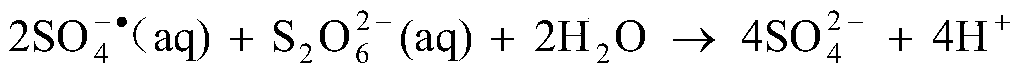

Method used

Image

Examples

Embodiment 1

[0029] MnSO in the manganese ore desulfurization liquid to be treated 4 The content is 125.1g / L, MnS 2 o6 Content 7.35g / L, temperature 10°C, pH=7.0. Add 4.0g sodium persulfate therein, stir 2 minutes and make it dissolve completely; Then add 1.28g ferrous sulfate heptahydrate, stirring speed is 50r / min, reacts 0.5 hour, records MnS in the solution after reaction 2 o 6 The content is 2.95g / L.

Embodiment 2

[0031] MnSO in the manganese ore desulfurization liquid to be treated 4 The content is 139g / L, MnS 2 o 6 The content is 15.90g / L, the temperature is 70°C, and the pH=1.0. Add 12.0g sodium persulfate wherein, stir 2 minutes and make it dissolve completely; Then add 0g ferrous sulfate heptahydrate, stirring speed 400r / min, react 5 hours, record the MnS in the solution after reaction 2 o 6 The content is 3.82g / L.

Embodiment 3

[0033] MnSO4 content in the manganese ore desulfurization liquid to be treated is 133.5g / L, MnS 2 o 6 The content is 16.89g / L, the temperature is 10°C, and the pH=7.0. Add 14.0g potassium persulfate wherein, stir 5 minutes and make it dissolve completely; Then add 2.89g ferrous sulfate heptahydrate, stirring speed is 50r / min, reacts 0.5 hour, records MnS in the solution after reaction 2 o 6 The content is 1.86g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com