Austenitic steel material having excellent hydrogen-embrittlement resistance

A technology of resistance to hydrogen embrittlement and austenite, applied in the field of austenitic steel, can solve the problems of reducing the stability of austenite, reducing ductility and toughness, disadvantageous cost, etc., and achieving the effect of excellent resistance to hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

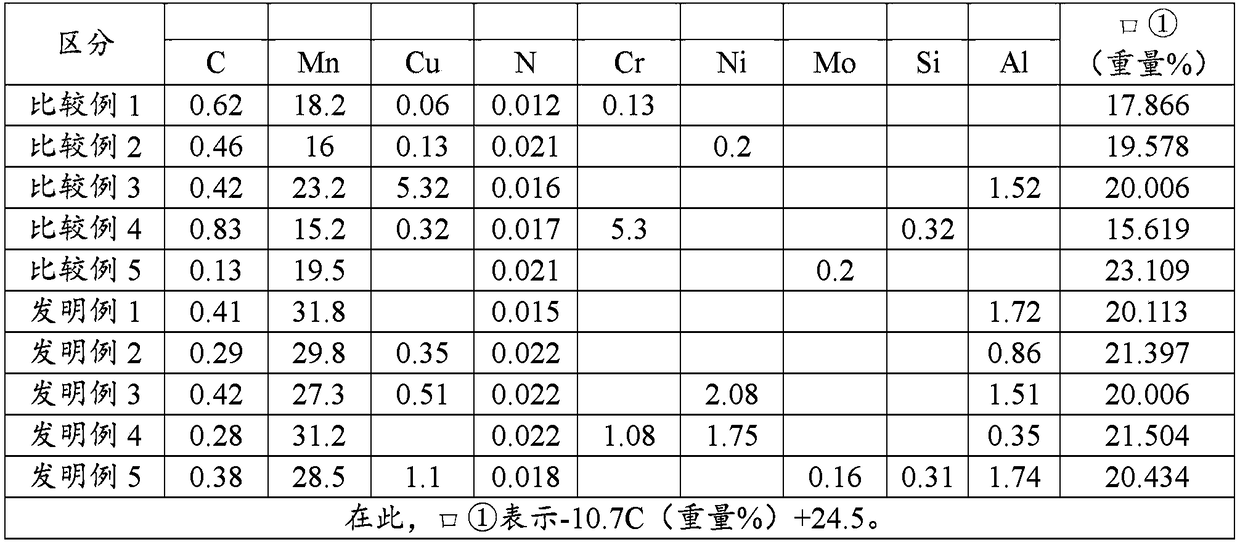

[0054] Hereinafter, the present invention will be described in more detail through examples. However, the descriptions of such examples are only for illustrating the practice of the present invention, and the present invention is not limited by the descriptions of such examples. This is because the scope of the rights of the present invention is determined based on the contents of the claims and the contents reasonably deduced therefrom.

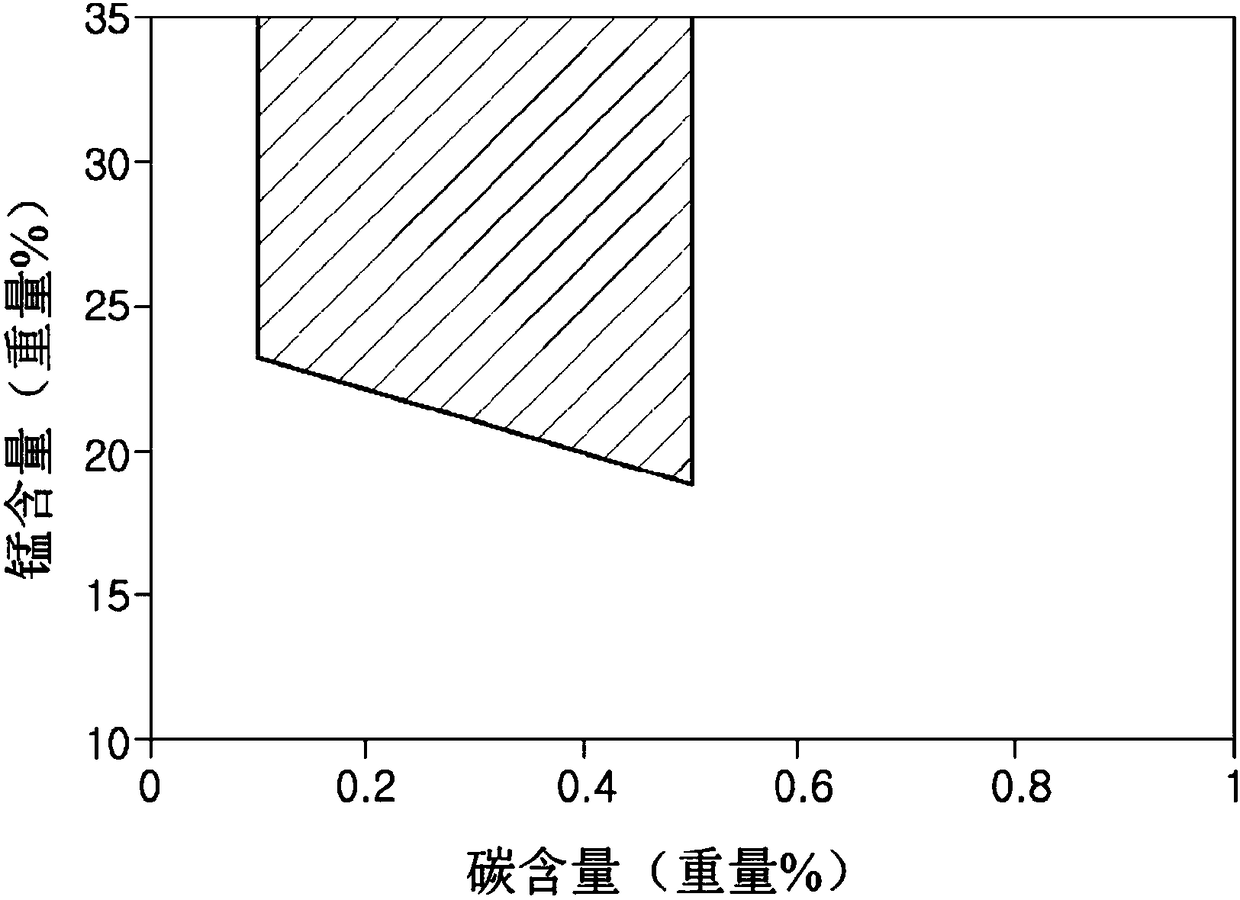

[0055] After preparing a slab having the composition of Table 1 below, it was hot rolled and cooled to prepare a rolled material. At this time, all the process conditions except the finish rolling finish temperature and cooling rate were controlled in the same way in all examples, and the finish rolling finish temperature and cooling rate are shown in Table 2 below. Please refer to Comparative Example 5, which does not describe the cooling rate in Table 2, indicating that simple air cooling was implemented.

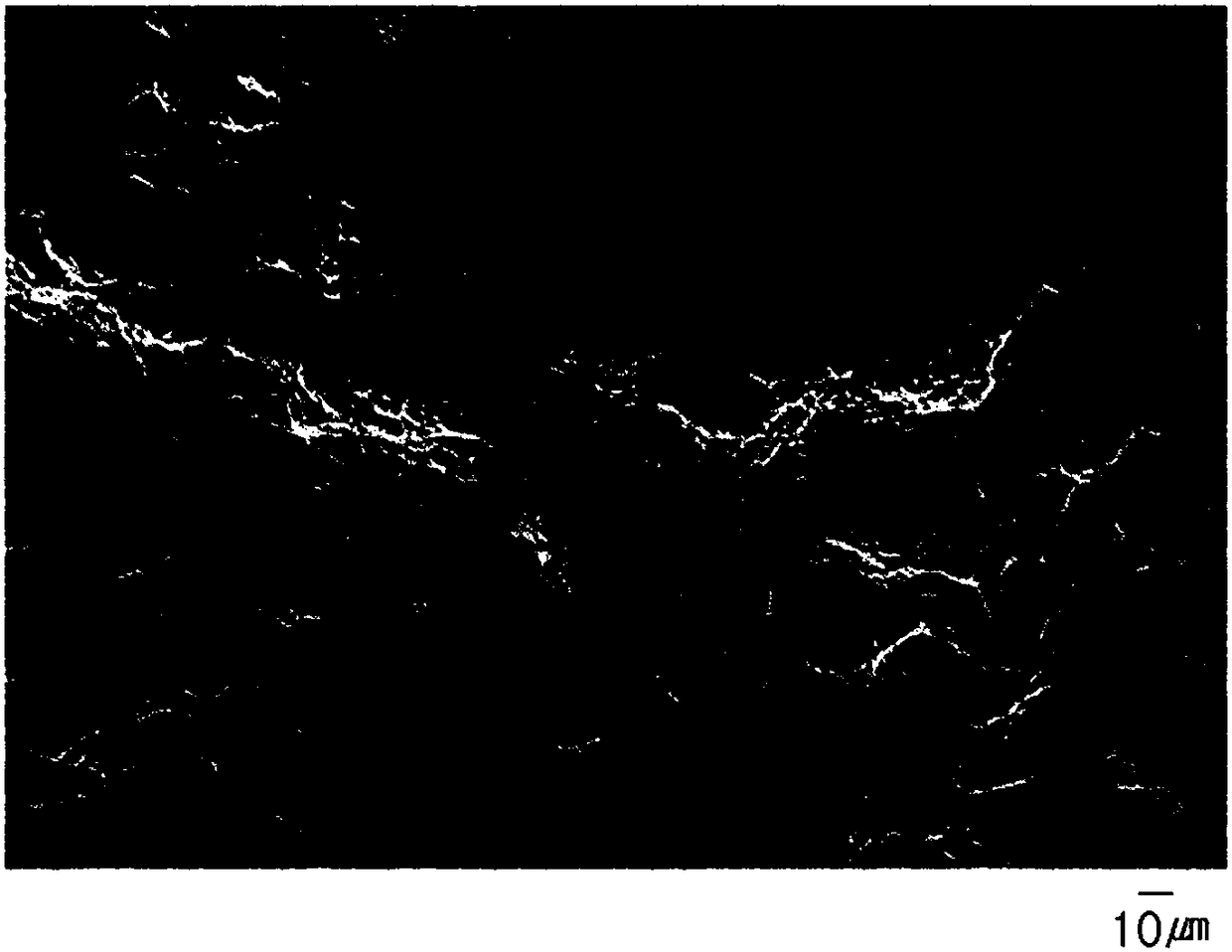

[0056] Then, the microstructur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com