Laser control deep scarification, land preparation and residue plastic film pickup all-in-one machine

A technology of residual film picking and integrated machine, which is applied in the direction of collectors, agricultural machinery and implements, shovels, etc., can solve the problems of shallow picking depth, single function, and difficulty in picking up broken and residual films, so as to ensure flatness and avoid Effect of secondary pollution and improvement of farmland environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

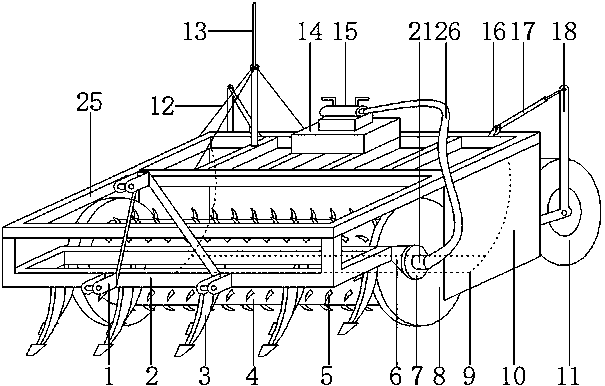

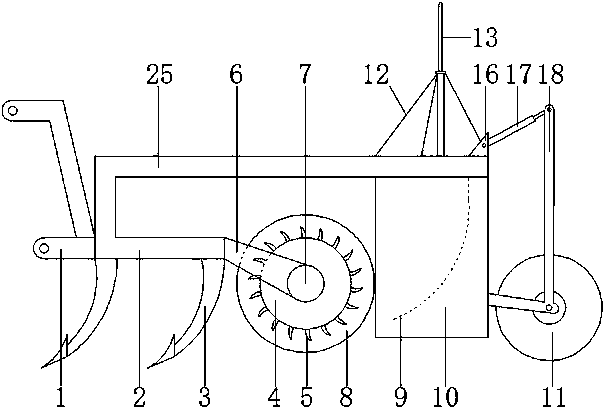

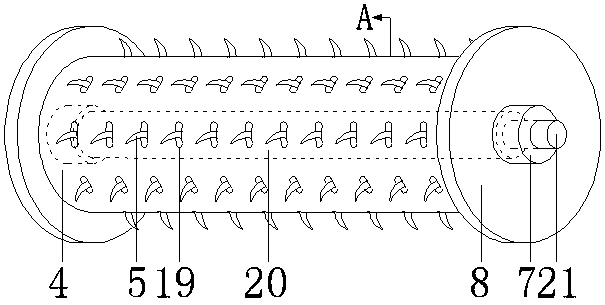

[0025] Such as figure 1 , 2 , A kind of laser-controlled subsoiling and soil preparation residual film picking machine shown in 3 and 4 includes a frame 25 and a subsoiling mechanism. The front part of the frame 25 is fixedly connected with a traction mechanism 1. The subsoiling shovel 3 is fixedly connected below it, and the top of the subsoiling frame 2 is fixedly connected to the bottom of the frame 25. The laser-controlled subsoiling and land preparation residual film picking machine also includes a picking mechanism, a leveling mechanism 10, a pressing roller 11, and a laser receiver. 13 and a hydraulic control device 14, the pick-up mechanism includes a pick-up roller 4 and a road wheel 8, the road wheel 8 is coaxially connected to the two ends of the pick-up roller 4 through the wheel shaft 20, and the two ends of the wheel shaft 20 are connected with bearings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com