Sowing furrowing profiling device

A profiling device, seeding and ditching technology, applied in the direction of excavation/covering trenches, fluid pressure actuation devices, planting methods, etc., can solve problems such as difficulty in reaching the sowing depth, affecting crop planting yield, and field emergence rate , to achieve the effects of displacement control, good field adaptability, and precise displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

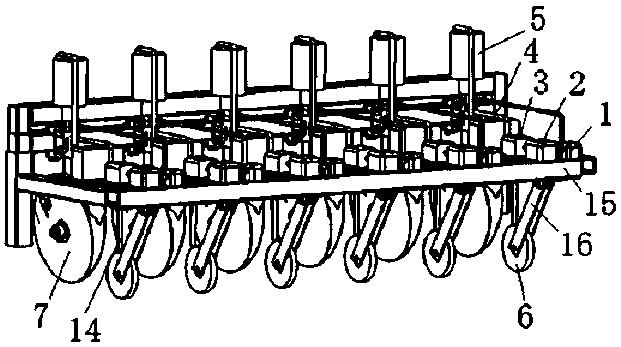

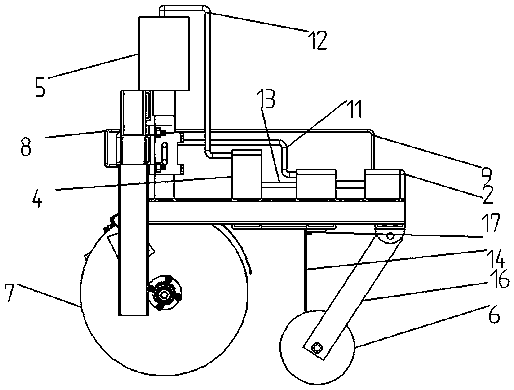

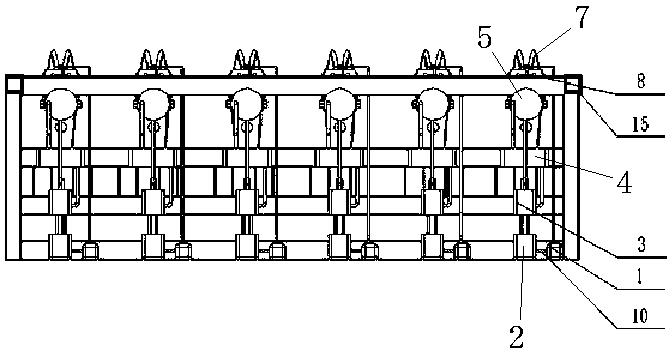

[0015] Such as figure 1 - Figure 4 As shown, an embodiment of a sowing ditching profiling device of the present invention is mainly composed of 1. controller, 2. motor, 3. variable pump, 4. servo cylinder, 5. hydraulic cylinder, 6. profiling wheel, 7. Disc opener, 8. Rear displacement sensor, 9. First signal pipeline, 10. Second signal pipeline, 11. First hydraulic pipeline, 12. Second hydraulic pipeline, 13. Third hydraulic pressure Pipeline, 14. variable pump moving servo slide valve slide rod, 15. frame, 16. profiling wheel support frame, 17. front displacement sensor, 18. two-position four-way solenoid valve. Wherein the front bottom of frame 15 is pivotally connected to the profiling wheel support frame 16, the bottom of the profiling wheel support frame 16 is pivotally connected to the profiling wheel 6, and the rear bottom of frame 15 is pivotally equipped with disc ditch opener 7, and the bottom of frame 15 Motor 2, variable pump 3, servo cylinder 4 and hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com